Printer hotend temperature lower than indicated and causing jams and under extrusion

The problem,

print jobs fail due to extreme under extrusion or nozzle jams.

I have disassembled the extruder, cleaned everything and replaced the PEFT tube and nozzle. Reinstalled it all with proper clearances and thermal paste IAW the prusa guide. Tried printing, this is what I found.

PLA will not print efficiently with any temperature below an indicated temperature 240C.

PETG will not print correctly below and indicated temperature of 260C

This is 25C higher than those I've used for over 2 years.

Anyone know why this would happen?

I have printed two projects at these higher temperature with no problems, but I'm concerted the temperature error will continue to be a problem.

Anyone have any ideas?

nd temperatue below 240C. PETG

Best Answer by Lynn:

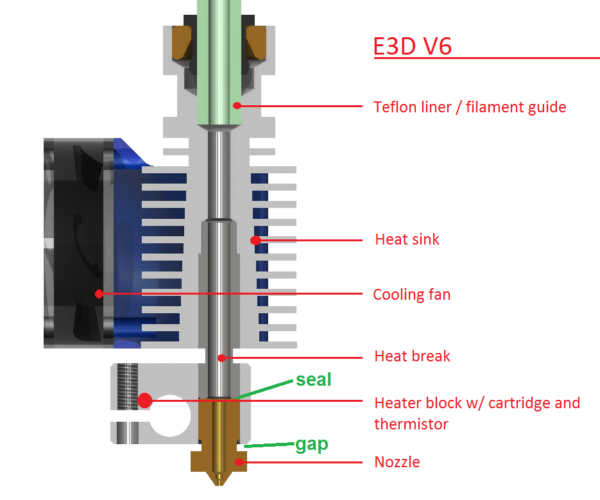

As it turned out, I found that the nozzle block was not fully engaged with with the heat break tubing. This caused the nozzle to bottom out against the nozzle block instead of contacting heat break. This allowed an air gap between the nozzle and the heat break, which collected filament and jammed up the works. I didn't discover this until I again dissembled the entire hot end and noticed how loose the nozzle block was, and there was a wad of plastic between the nozzle and the hotend.

Anyway, after I tightened everything up it worked normally again.

RE: Printer hotend temperature lower than indicated and causing jams and under extrusion

The problem,

print jobs fail due to extreme under extrusion or nozzle jams.

I have disassembled the extruder, cleaned everything and replaced the PEFT tube and nozzle. Reinstalled it all with proper clearances and thermal paste IAW the prusa guide. Tried printing, this is what I found.

PLA will not print efficiently with any temperature below an indicated temperature 240C.

PETG will not print correctly below and indicated temperature of 260C

This is 25C higher than those I've used for over 2 years.

Anyone know why this would happen?

I have printed two projects at these higher temperature with no problems, but I'm concerted the temperature error will continue to be a problem.

Anyone have any ideas?

nd temperatue below 240C. PETG

Do you use the original E3D hotend with brass nozzle? You might want to check the thermistor. It should have an internal resistance of 100k ohms at an ambient temperature of 25 degrees C.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Printer hotend temperature lower than indicated and causing jams and under extrusion

@karl-herbert

I have the original hotend supplied from Prusa, except for the nozzle which I've replaced multiple times.

I haven't checked the thermistor resistance at 25c because when it is cold the hot-end and bed temperatures on the display are the same. This morning they both read 26C. But I will, just for the data point

I thought maybe some temperature offset was being enforced by software. My last printer had a setting to offset temperature(don't know why), but I couldn't find any setting in the slicer or on the printer menu to do this.

Any solution yet?

Hello, I think that I am having the same issue. Have you discovered a solution to this yet?

Any solution yet?

You could make corrections in the firmware (temperature table), but this might be a bit difficult for most users. The easiest way is to simply set the temperature in the slicer 10-20 degrees higher.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

As it turned out

As it turned out, I found that the nozzle block was not fully engaged with with the heat break tubing. This caused the nozzle to bottom out against the nozzle block instead of contacting heat break. This allowed an air gap between the nozzle and the heat break, which collected filament and jammed up the works. I didn't discover this until I again dissembled the entire hot end and noticed how loose the nozzle block was, and there was a wad of plastic between the nozzle and the hotend.

Anyway, after I tightened everything up it worked normally again.