Re: Playing with the air nozzle design

Hi Stahlfabrik, and thank you for your comments.

When I designed the nozzle, I searched 5-6 different manufacturers of this fan type to see what dimensions they had.

Almost all manufacturers had the same measure of fan outlet, 15.0 ± 0.5 x 20.0 ± 0.5 mm. I also measured on my own fan and used these.

If I decrease the measurements a further 0.1 mm, I do not think my fan would fit anymore. With the current dimensions, I have to push it into the collar.

It may be that different fans have some different dimensions, or my filament shrinks a bit more than the filament you used.

The Gcode file I attach has a different setting of cooling than Prusa ABS use, and it may decrease the string formation.

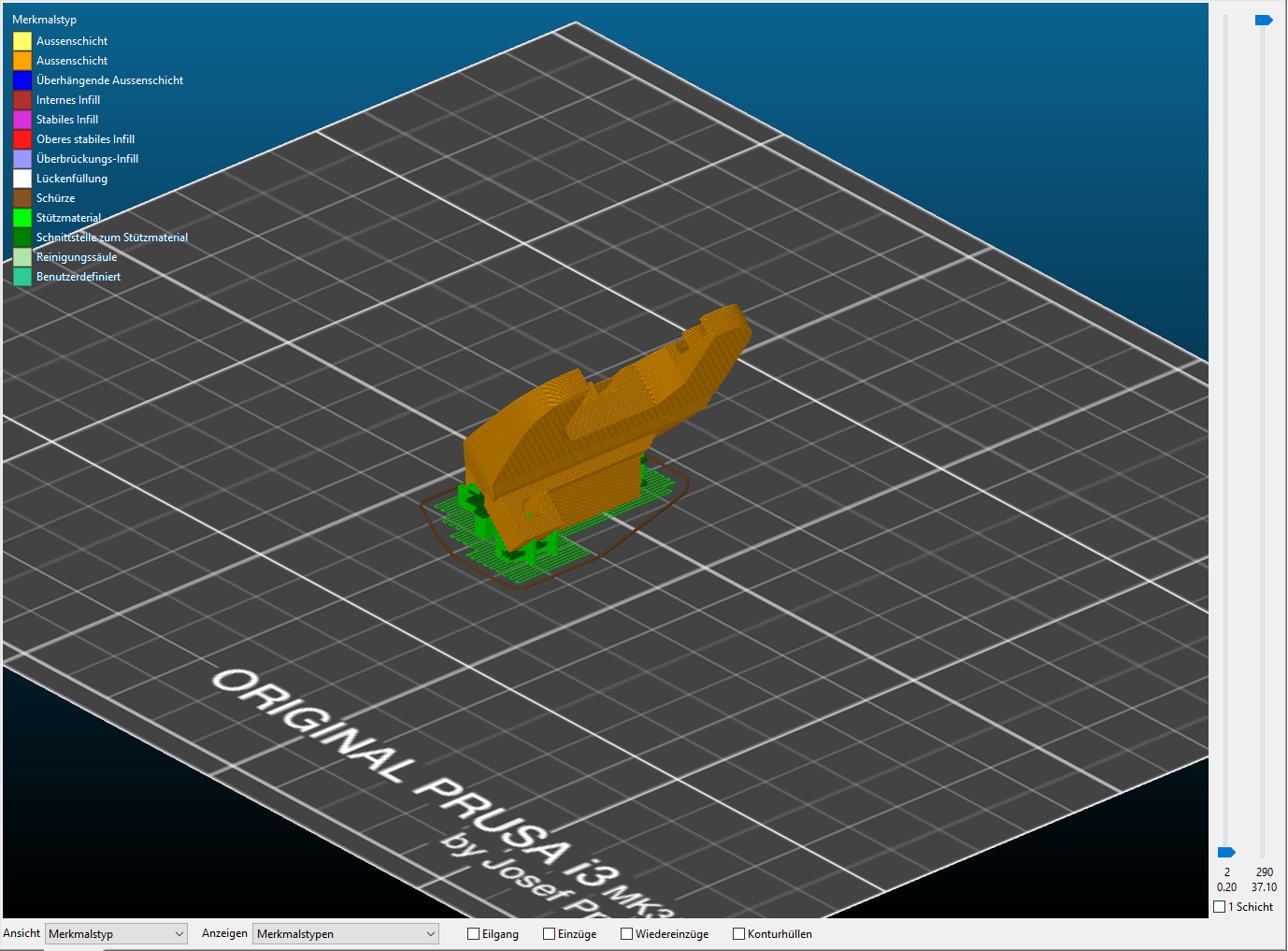

0.15 mm layer height also gets better than 0.20 mm, but as you say, I can see a tendency to problem in the left channel (see figure).

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

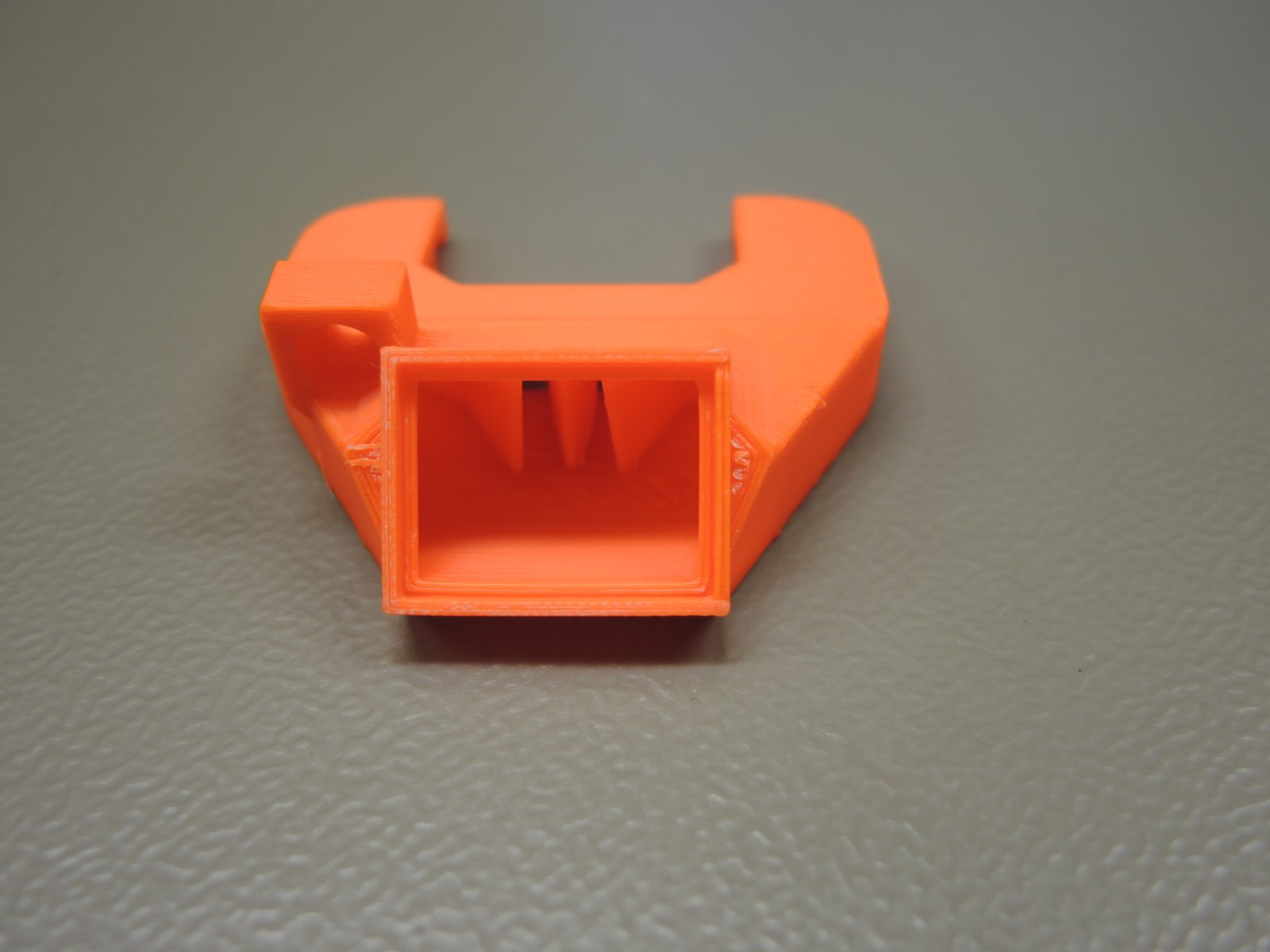

that sort of interior finish will ,I think, result in quite a turbulent air flow I don't know if that will be good or bad for this application but in general for efficiency you want internal airflow to me laminar. consider induction and exhaust flow in combustion engines and basic flow calculations in HVAC

Re: Playing with the air nozzle design

For this reason, it is better to print the nozzle in a low resolution. But we must accept this unwilling turbulence because we can not buy cast nozzles with a completely smooth inside.

I will test with a few different internal geometries to see if the surface can be smoother. We also do not know if this turbulence has a negative effect on the outcome.

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

Hi Stahlfabrik, and thank you for your comments.

When I designed the nozzle, I searched 5-6 different manufacturers of this fan type to see what dimensions they had.

Almost all manufacturers had the same measure of fan outlet, 15.0 ± 0.5 x 20.0 ± 0.5 mm. I also measured on my own fan and used these.

If I decrease the measurements a further 0.1 mm, I do not think my fan would fit anymore. With the current dimensions, I have to push it into the collar.

Hi!

My comment is not so much about making the opening tighter, but to add maybe a slit or a small cavity (better) so that the "Bulge" right in the middle of the side of the fan has a place to go. Because I think that this protruding part on the side of the fan pushes the fan away and thus creates the gap that I talk about.

You can look at the original R3 nozzle: There is a (too large) gap for the fan's bulge on its side wall to fit in.

The goal would be to make the fan as easy to fit as possible while also making the connection as air tight (and inside turbulence free) as possible.

Next time I will check out your GCODE!

Thx!

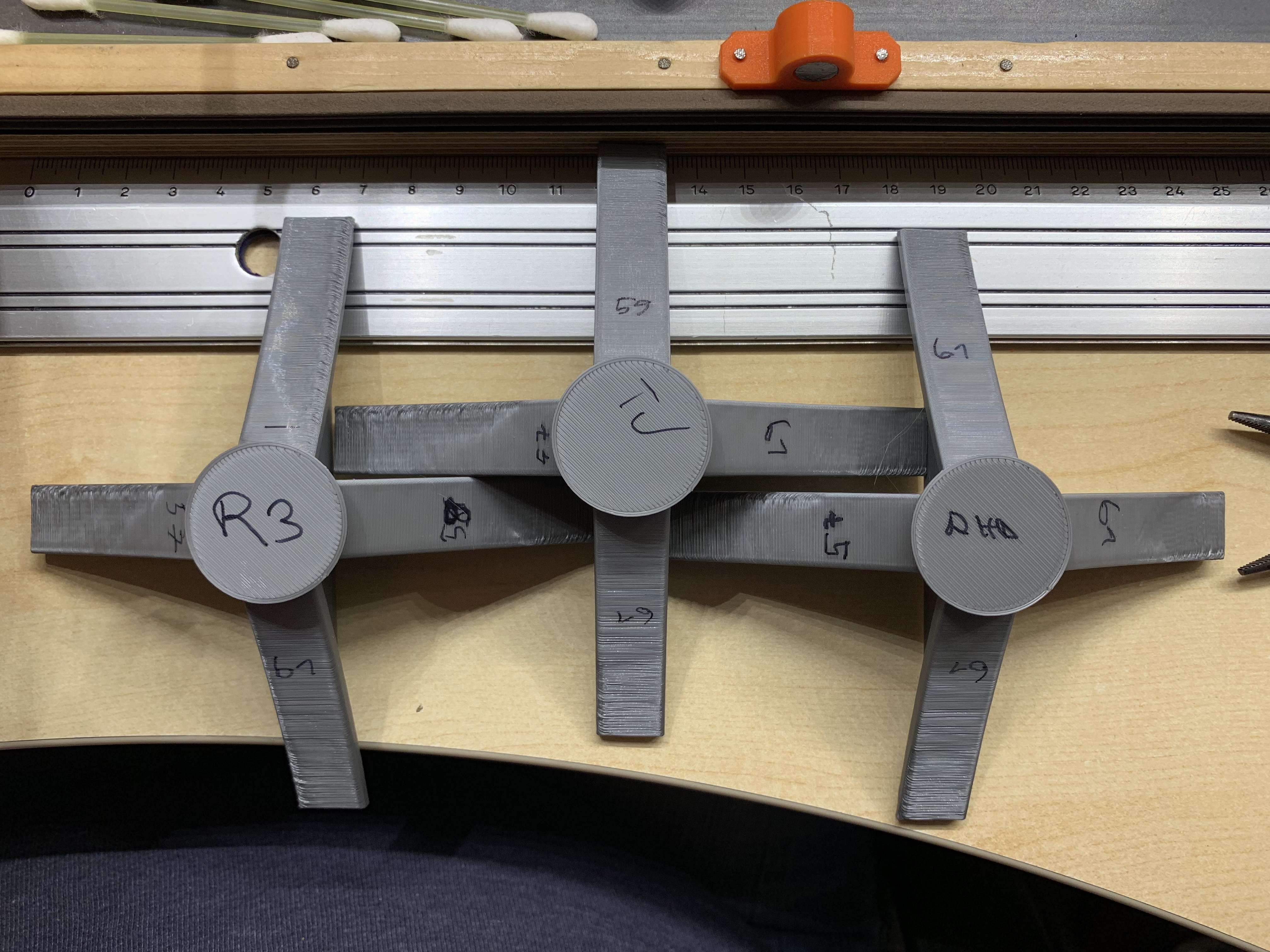

EDIT: By the way: my last test shows that your nozzle generally performs great - but your nozzle, like the other Thingiverse nozzle and stock nozzle have weaker cooling on the right side than on all other sides. The performance on front, left and especially back is very good!

The stock R3 nozzle is sooo bad in the back. Really astonishing! Prusa Research should adopt YOUR design!

Re: Playing with the air nozzle design

For this reason, it is better to print the nozzle in a low resolution. But we must accept this unwilling turbulence because we can not buy cast nozzles with a completely smooth inside.

I will test with a few different internal geometries to see if the surface can be smoother. We also do not know if this turbulence has a negative effect on the outcome.

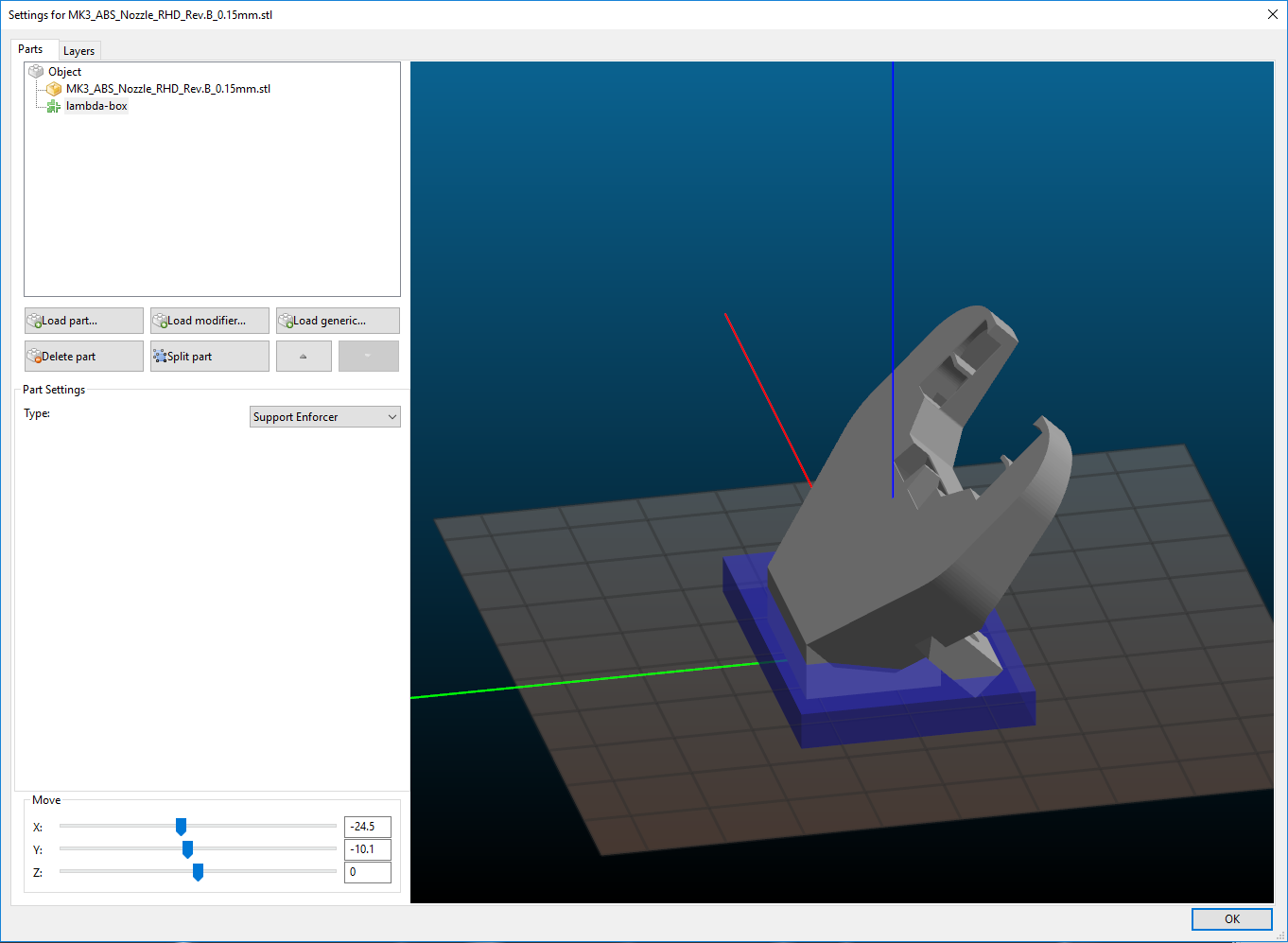

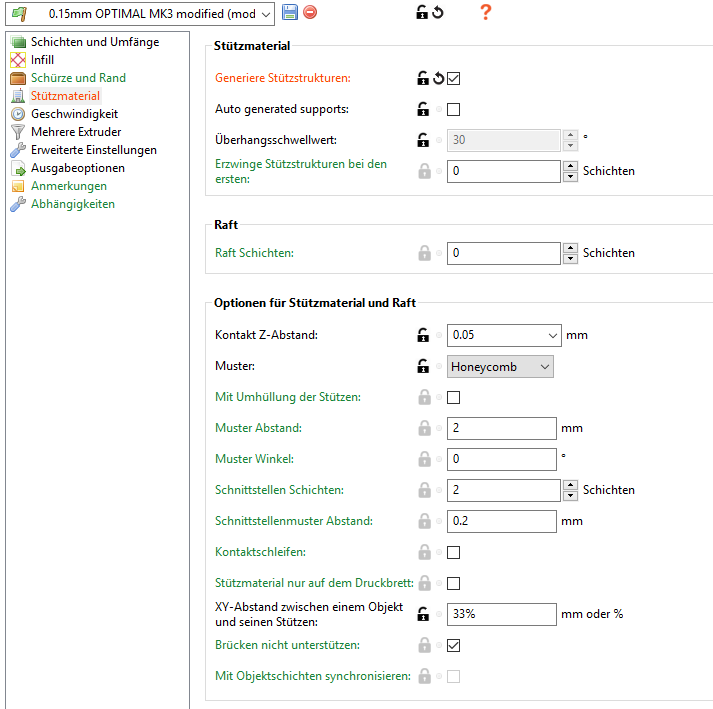

Hello, thanks for your design, very well done! I tried to find a good position for printing by turning the air nozzle with Slic3r-Pe. I printed the following rotations, printed with 0.15mm ABS:

1st x-axis 135 °

2nd z-axis 90 °

In addition the Support Enforcer:

Box: 40, 30, 4.8 mm pushed under the air intake.

The air nozzle is thus free of overhangs.

Greetings Holger

2x Personal MK3IR-BMG09 (Full) BEAR + MMU3 mod., ...

Re: Playing with the air nozzle design

Holger that is genius! I need to try that!

EDIT:

What settings did you use? Is that ABS? Did you use cooling fan?

Re: Playing with the air nozzle design

Hi!

My comment is not so much about making the opening tighter, but to add maybe a slit or a small cavity (better) so that the "Bulge" right in the middle of the side of the fan has a place to go. Because I think that this protruding part on the side of the fan pushes the fan away and thus creates the gap that I talk about.

You can look at the original R3 nozzle: There is a (too large) gap for the fan's bulge on its side wall to fit in.

The goal would be to make the fan as easy to fit as possible while also making the connection as air tight (and inside turbulence free) as possible.

Thx stahlfabrik, that's my thought too.

Holger

2x Personal MK3IR-BMG09 (Full) BEAR + MMU3 mod., ...

Re: Playing with the air nozzle design

Holger that is genius! I need to try that!

EDIT:

What settings did you use? Is that ABS? Did you use cooling fan?

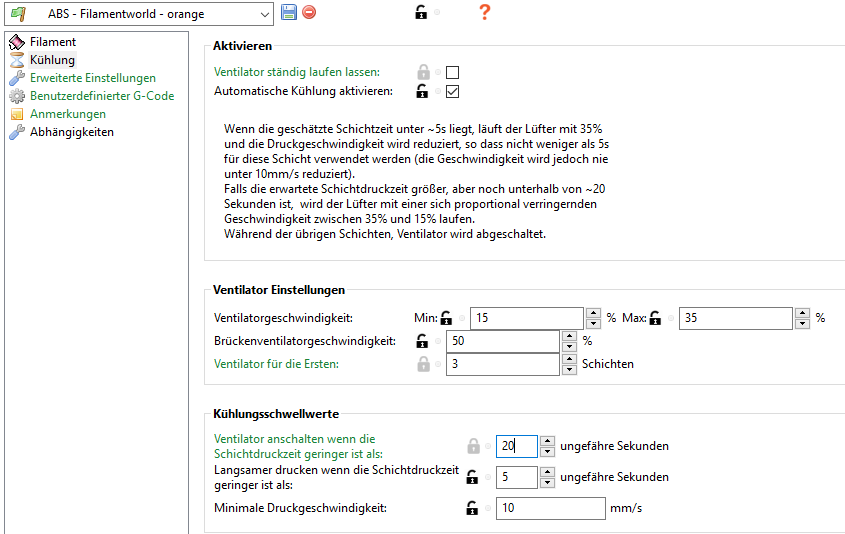

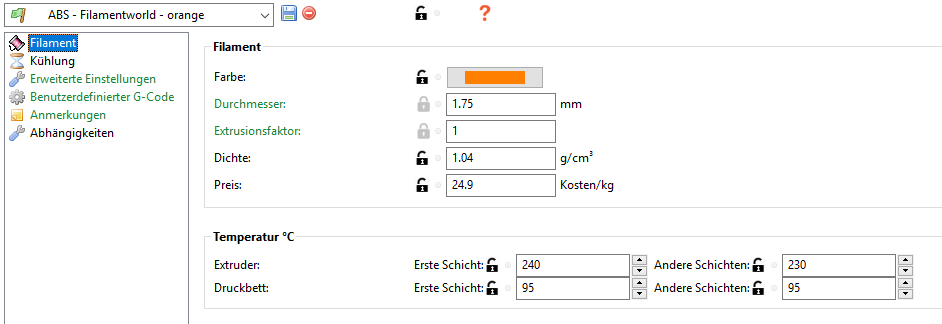

Yes, I use the cooling fan. It's Filametworld ABS

Cooling Parameter:

2x Personal MK3IR-BMG09 (Full) BEAR + MMU3 mod., ...

Re: Playing with the air nozzle design

Sweet thank you!

Such a filigreed print is imho hard to achieve with abs without using a fan, right?

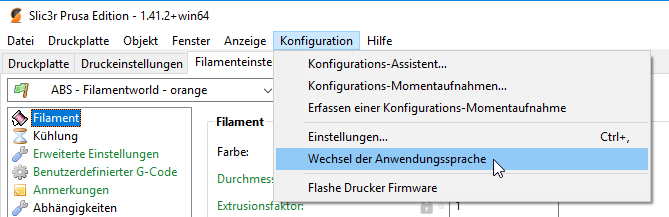

by the way: Warum spricht dein Slicer deutsch?;-) My slic3r always speaks English to be - was not even aware there is localization 😆

Re: Playing with the air nozzle design

😀

ABS and PETG are my favorite filaments and the cooling needs to be adapted to each object.

Set language, you can see here:

My first ABS 3D-Benchy with the new RHD air-nozzle, print direction was z=315°:

2x Personal MK3IR-BMG09 (Full) BEAR + MMU3 mod., ...

Re: Playing with the air nozzle design

Thanks for that and also for your support settings! Very interesting - have not yet dared to mess with them - but I am not happy how supported parts look with default settings

Re: Playing with the air nozzle design

The Prusa settings are mostly settings for highest speed, not for best quality 😉

It's good for the benchmark tests. 🙂

2x Personal MK3IR-BMG09 (Full) BEAR + MMU3 mod., ...

Re: Playing with the air nozzle design

Thank you Holger for your info.

It is always interesting when someone thinks outside the box and turn thingss upside down. I have to test that.

For your info, I work with a revision C of the nozzle. It should give a slightly better flow in the front outlets, and that there is a small outlet in the collar for the heels "bulge" of the fan.

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

For your info, I work with a revision C of the nozzle. It should give a slightly better flow in the front outlets, and that there is a small outlet in the collar for the heels "bulge" of the fan.

So....when will Rev C be available? 😀

Re: Playing with the air nozzle design

For your info, I work with a revision C of the nozzle. It should give a slightly better flow in the front outlets, and that there is a small outlet in the collar for the heels "bulge" of the fan.

So....when will Rev C be available? 😀

I work as fast as I can, but it takes some time for each simulation and printing of prototypes 😀

But give me a day or two to.

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

For your info, I work with a revision C of the nozzle. It should give a slightly better flow in the front outlets, and that there is a small outlet in the collar for the heels "bulge" of the fan.

So....when will Rev C be available? 😀

I work as fast as I can, but it takes some time for each simulation and printing of prototypes 😀

But give me a day or two to.

Your work is amazing. This fan is the best one I've tried so far. Very good airflow. Thank you for your efforts. ☺️🍻

Re: Playing with the air nozzle design

For your info, I work with a revision C of the nozzle. It should give a slightly better flow in the front outlets, and that there is a small outlet in the collar for the heels "bulge" of the fan.

Hi RHDreambox!

I will print revision B now the Holger way.

Regarding the revision C: I think airflow on the front is already quite good. It is especially also good on the back (as I mentioned before). It is Ok on the left and like all other nozzle lacks compared to the other directions on the right. If you can generally increase flow and that increase is toward the from then go for it:-) But if you would take away air from lets say the back or sides than I would not suggest to increase from air flow. The stock R3 nozzle has the problem that it basically just blows from the front, a little on the sides and not at all on the back:-)

But I trust in your decisions! The nozzle so far is a winner:-)

Best regards

On the picture you can see that all reach 61 degrees in the front. And on the other directions yours performed better or the same than the others.

Re: Playing with the air nozzle design

For this reason, it is better to print the nozzle in a low resolution. But we must accept this unwilling turbulence because we can not buy cast nozzles with a completely smooth inside.

I will test with a few different internal geometries to see if the surface can be smoother. We also do not know if this turbulence has a negative effect on the outcome.

I was concerned that you might want to introduce some surface roughness to your flow results... to avoid being fooled by the pretty patterns they provide as they assume a smooth interior finish.

but if a smooth interior for the air flow is desired you could do a clamshell snap together version and seal with something like aluminum or Stainless steel heating duct tape