Parts ripped off bed, nozzle crashes, everything fails - What's happening?

Hello,

I've been printing on my Prusa i3 MK3S for quite a while. Usually very good quality prints.

I print full sets of chess pieces. Each set uses about 350 grams of filament and takes just under 24 hours to print. There are 16 parts with the lower half being solid infill.

I've printed LOTS of these, with lots of slight iterations on the design. I use Prusaslicer with no issues.

This problem has happened once before, but yesterday and today it happened again and destroyed 500+ grams worth of prints. I wake up to a nozzle squirting out filament in mid-air, some pieces on the floor, and most half-printed.

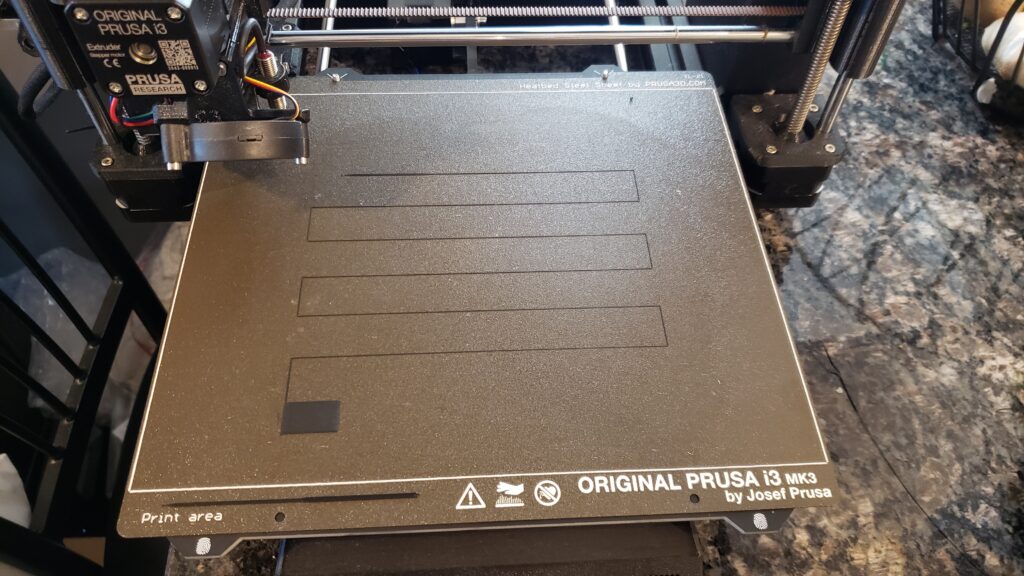

This picture shows an example. (Note: I removed most of the pieces before taking the picture)

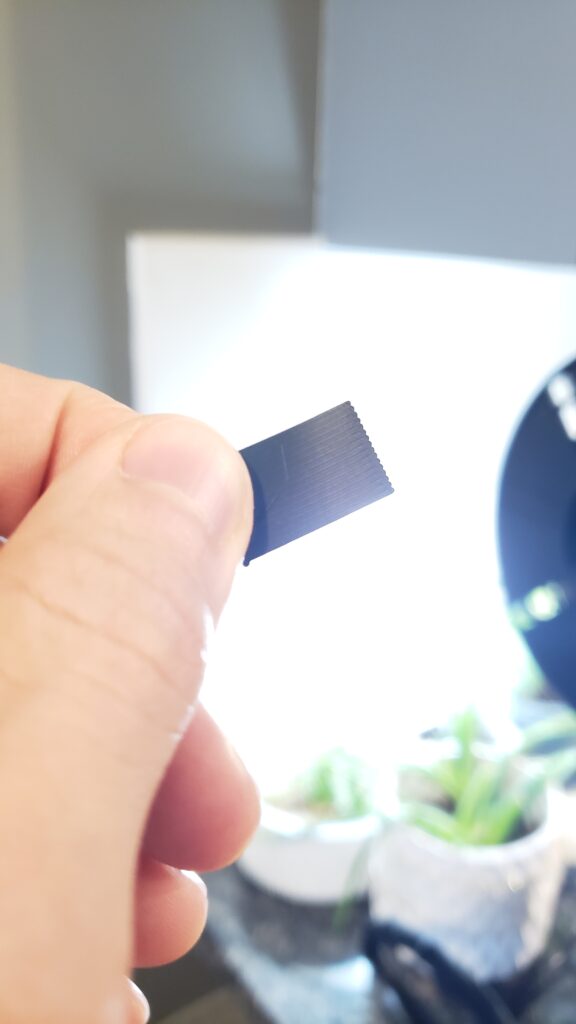

When this happened before, I actually observed the issue. It's printing fine, then once it gets to the top layers of the rook, the rook gets ripped off the build plate, the nozzle crashes into it, and then the rest of the pieces struggle to hold on as a bunch of things start flying around. This next picture shows the point of impact on the rook:

Another strange thing is the OTHER rook that was on the build plate actually finished printing.

The adhesion to the build plate is GREAT. Every piece requiring quite a bit of force to pull off (I use a white glue stick)

Last point - my white filament (same manufacturer - Eryone) printed successfully twice using the SAME GCODE. Upon switching to the black filament this problem arises.

Has anybody seen this before? Any thoughts for debugging?

Fabio

RE:

Please show us the bottom of that rook.

I presume that is not Flex filament, even if it is you have too much glue on the print sheet. With a print sheet so smeared you are bound to have adhesion issues, clean it.

Solid infill is almost always a mistake and requires very precise extrusion calibration, 80% will be more than enough to give a good playing feel and supply voids to act as crack stoppers in the event of stressed parts.

For serious play I always print 17 pieces per side so I assume these are not to tournament standard dimensions. You can save a lot of filament by incorporating drop-in weights in the design.

Cheerio,

RE: Parts ripped off bed, nozzle crashes, everything fails - What's happening?

I agree with @diem, way too much glue on that bed. I almost never use glue on my bed, if I have lifting it's usually either due to my z-offset too high or my bed is dirty or both. With that much glue you're not actually getting adhesion on the bed, you're part is swimming in a puddle of glue and you're relying on the surface tension of the glue to keep things in place.

If you really want to use glue take a look at this video he shows you how to use glue sparingly to improve your bed surface.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Parts ripped off bed, nozzle crashes, everything fails - What's happening?

I like @diem's idea of drop-in weights (a piece of metal or even sand) to give the pieces some heft. 100% is almost never required.

But I'm not sure I'd blame the glue stick. Not saying it's not playing a role but I've seen worse than this print just fine. I'm wondering if you have a bit of overextrusion and the nozzle catches on infill or a surface feature. I'd start by calibrating the extrusion multiplier.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE:

Diem and Bob,

Thanks for your replies!

I actually had washed the bed and used much less glue on the first print that failed at the same point, then I added more glue before the second one seen in the picture.

The parts that didn't rip off were very well adhered to the plate and took quite a bit of force to remove by hand. I've never really had adhesion issues with this glue stick. Here's a picture of the bottom of the rook. Maybe z-height is too high indeed. This would be confusing to me considering how well-adhered everything else is.

About the pieces - these are meant to be tournament compliant - and they are - and I do print 17 pieces. I was able to recover most of the pawns and already started removing more pieces (why there are few in the pic)

I tried doing drop-in weights previously, but the inner perimeters took extra time to print, even compared to the bottom solid layers. I do like to idea of 80% instead of solid to allow for expansion though! (Can I do "bottom solid layers" at different densities?)

I only have 10mm of bottom solid layers - the failure occurs higher in the pieces where it's 16% infill.

Fuchsr - it could be an overextrusion issue! I wonder if it over-extrudes, solidifies, and then the nozzle crashes? I assume there's a guide online for calibrating. I will find it and report back

Thanks everyone. Gonna keep experimenting.

Fabio

RE: Parts ripped off bed, nozzle crashes, everything fails - What's happening?

I assume there's a guide online for calibrating

Many different ways you can do it. I simply print a hollow box without a top and measure the width of the walls with a high precision caliper. Then calculate what extrusion multiplier I need to get to the width specified in the perimeter width settings.

If you print walls thicker than one, remember that two adjacent perimeter lines slightly overlap, so if your extrusion width is 0.45, a two-line thick wall is not 0.9 but rather 0.86 mm.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Parts ripped off bed, nozzle crashes, everything fails - What's happening?

The base on that piece shows classic too high z-offset. You need to lower that sucker by quite a bit. There shouldn't be any gaps between the filament on that first layer.

Clean your bed, do a first layer calibration and show us photos of the result. 2 images, a wide image so we can see the full bed and a close up of the rectangle at the end.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Parts ripped off bed, nozzle crashes, everything fails - What's happening?

Alright. I will print the box shortly.

Cleaned the bed, added a very small amount of glue.

Did first layer cal and dropped the first layer by apx. 0.15mm. Here's the result. I included a picture with a light in the background. I think I closed all gaps.

RE:

I have to say, that's a pretty good looking first layer. You dropped it by .15? That's quite a bit. I'd do a test print now.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Parts ripped off bed, nozzle crashes, everything fails - What's happening?

One other question, I should have included in my last post, what are you using PLA? PETG? Something else? In my experience PETG works really well with the textured bed, but I find PLA works better on the smooth bed.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE:

Going to play with extrusion multiplier calibration, then run a print overnight. I'll let you all know in 24 hours how it went.

Really appreciate your help!

It is PLA btw!

Fabio

RE: Parts ripped off bed, nozzle crashes, everything fails - What's happening?

PlA on the textured bed doesn't stick as well in my experience. Do you have the smooth bed? You might find you don't need glue on the smooth bed.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE:

If this is happening once you print uneven surfaces at the top of the part (like the battlements on the tower, if this is the right word), I wonder whether the extruder is not lifting high enough in time whilst shifting from one battlement to the next, possibly crossing diagonally across another which is 0.2mm higher printed than the next one, and crashes into the part, either the nozzle or the PINDA. I do recall this happened once to me; I can´t put the finger on it anymore but I believe I solved it with changing the horizontal orientation of the part, i.e. rotating it on the plate. This might explain why it happened to one figure only.

I was a rookie at 3D printing then and I guess it would have been solved easier by requiring the extruder to go a bit higher when changing positions between extrusions and there´s probably a setting for it in the Prusa Slicer.

Just my 2 cents

Chris

I try to give answers to the best of my ability, but I am not a 3D printing pro by any means, and anything you do you do at your own risk. BTW: I have no food for…

I'm not surprised that rook came loose, your calibration print is much better. You shouldn't need any glue... especially if you switch to a smooth sheet.

Cheerio,

RE: Parts ripped off bed, nozzle crashes, everything fails - What's happening?

Alright team, I had a few successful prints over the weekend. It is very difficult to tell what the solution was. I didn't want to risk ruining another batch (cause the failure happens so late) so I unscientifically changed several variables:

- Washed the build plate, applied the thinnest possible layer of glue

- Calibrated the Z-Axis offset for better contact area

- Doubled Z-Lift from 0.2mm to 0.4mm to avoid running top surface imperfections

- Calibrated extrusion multiplier (no change)

- Changed top surface fill pattern from Octagram Spiral to Concentric

- The Octagram Spiral rapidly shakes the parts as it approaches the center of the pattern. The shaking may have knocked stuff loose. I also noticed it conducted too much heat at that point and leaves a little raised crater which could have blocked movement. This also occurs in the solid infill pattern of small features like the rook "battlements" similar to what Chris was predicting

- Rearranged parts arbitrarily on the sheet

Thank you for getting me to think this through all the way. Best wishes.

Fabio

RE: Parts ripped off bed, nozzle crashes, everything fails - What's happening?

Thanks for the feedback and Happy Printing!

Chris

I try to give answers to the best of my ability, but I am not a 3D printing pro by any means, and anything you do you do at your own risk. BTW: I have no food for…