Nozzle catch

First, thanks to all the community for assisting in the first layer problems I was having.

I'm trying to print game tokens. The first layer is printing with a design. However, when I get up about 3mm the nozzle catches on the object. After the second fail I thought I'd come here to see if it was mechanical or software.

Basically it sticks until the blob is attached to the nozzle and then it pops off the bed.

[IMG_20190418_083759.jpg

[IMG_20190418_083759.jpg

Let me know if there are other factors needed or if this would be better on the Print Help forum.

Thanks 🙂

Re: Nozzle catch

That looks like you have two issues, over extrusion and poor bed adhesion, the token breaks free and moves around which causes the molten plastic to pool around the nozzle.

what slicer are you using? which profile,

what filament are you using?

what is the bottom side of the part looking like?

If your first layer Z is good, then you probably need to clean the build plate,

What I do, is take the build plate to the sink. squirt some detergent (Dish soap, dawn, or Fairy Liquid or similar) onto the build plate, scrub the surface through the detergent, with a clean scotchbright pad and wash off with clean hot water.... then dry with a clean paper towel.

DO not touch the surface of the build plate.

return the buildplate to the printer, and try printing again, but reduce the flow to 5% less than it is at the moment!

good luck,

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Nozzle catch

Slic3r PE 1.41.3+win64 with the ColorPrint 3D website for the layer filament changes.

Slic3r was set to bog standard 0.20mm Quality MK3 with Generic PLA on a i3 MK3S printer 15% fill density. No supports or brims. I didn't adjust any of the g-code which means (if I'm reading it right) the printer starts off at 215/55 and backs the nozzle heat to 210 after the first layer.

Would I use slic3r to reduce flow?

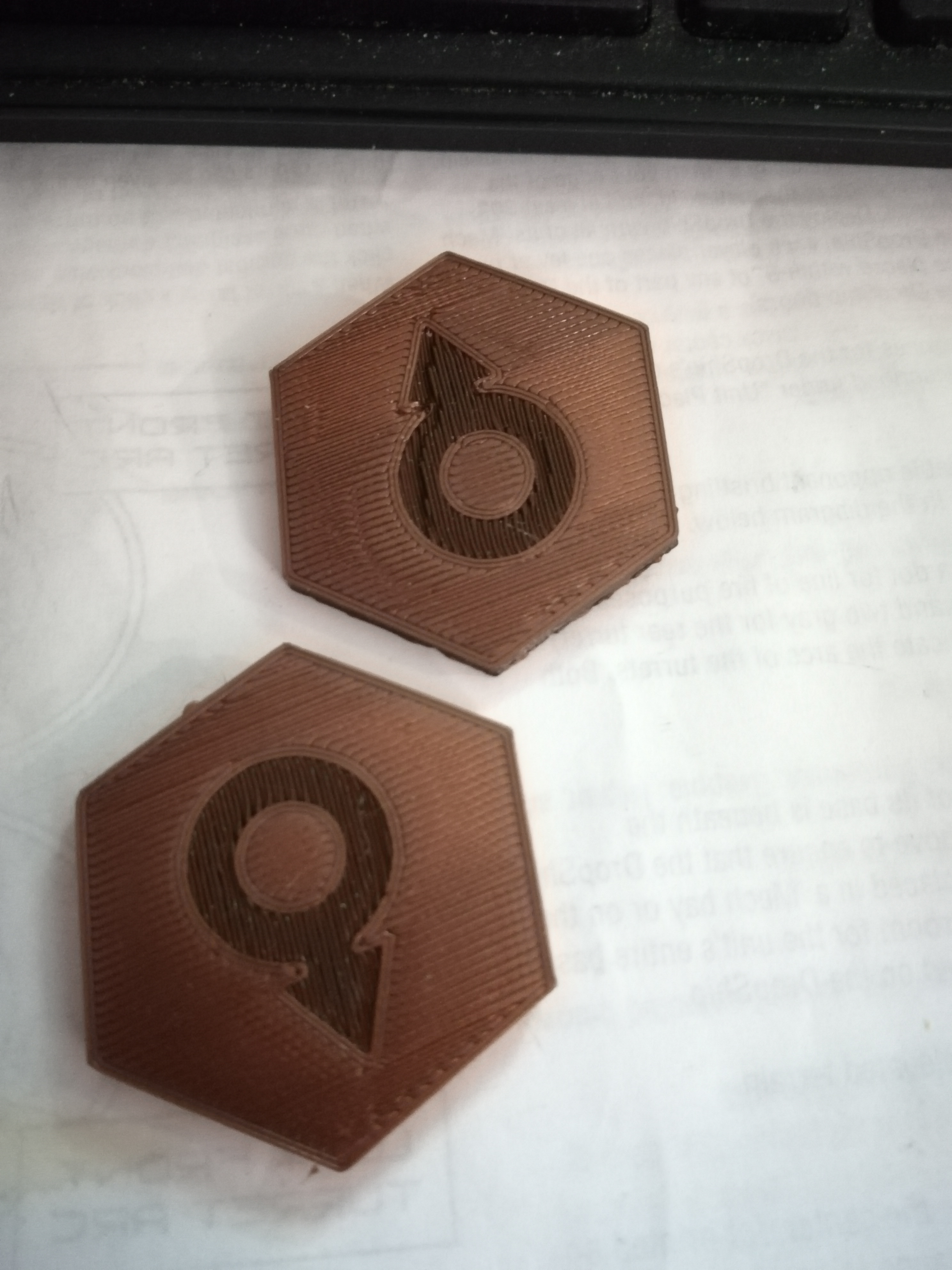

This is the bottom:

The copper is Amazon Basic and the dark brown is Spool3D (a Canadian company).

I've been trying to be extra diligent in my "keep the steel sheet clean". I have been using a paper towel as a wash cloth with the soap and rinsing off with hot tap water. The water is softened. A tech in chat suggested NOT using soap as the residue can stick. I take it the scotchbrite pad is non-abrasive so it doesn't harm the plate.

Everything prints in the centre of the plate. I never touch that area using pliers or a zip-tie spatula to pop off the object. I give the sheet a scrub-wipe with 99% isopropanol (even checked the best before date in case it was "stale")

This is my version of Dawn. I checked on line and this seems to be the closest thing to "no scent" as they have although apparently you can get Fairy dish soap on the American Amazon.

Re: Nozzle catch

Hi Margaret,

Language is a funny thing.

from the Soap wiki,

Soap is the term for a salt of a fatty acid[1] or for a variety of cleansing and lubricating products produced from such a substance. Household uses for soaps include washing, bathing, and other types of housekeeping,

from Dishwashing Liquid Wiki

Dishwashing liquid (BrE: washing-up liquid), known as dishwashing soap, dish detergent and dish soap, is a detergent used to assist in dishwashing. It is usually a highly-foaming mixture of surfactants with low skin irritation,

the Czech helpdesk, probably took the word Soap, literally... fatty acids are probably not a good idea on your buildplate.

dish Detergent liquid, is designed to dissolve oils and greases... but American English often refers to dish detergent, as Dish Soap... which can be confusing.

I use Fairy liquid or similar and water, in the UK, your Dawn should be similar(the label actually says 'Détergent à vaisselle')... I also use a clean pan-scrub, (scotchbright pad)

to slightly scour the PEI surface when scrubbing the grease and surface contaminants off... then rinse with clean hot water

after washing I use clean paper towels to remove the excess water. there should be no smearing on the freshly washed and dried surface.

cloths should not be used because they are often washed in conditioner, which can often leave a trace amount of conditioner material on the surface, which will diminish your adhesion.

i handle the build plate by the edges after cleaning, to prevent contamination.

I hope this helps...

your first layer looks a little odd, on the top piece the left hand side looks a little squashed, whilst the top right looks a little stringy...

let's leave that for the moment...you might like to look at this thread

have you measured the diameter of your filament? if it's over 1.75mm, you will get over extrusion, unless you change the value in your slicer filament diameter window...

your extrusion multiplier should be set to '1' in standard values, you can see in my example above that I have reduced that to 0.95 to reduce over extrusion.

as you are using the standard Slic3r generic pla profile, you are probably using a flow rate modifier of 95% caused by this line in your start gcode

M221 S{if layer_height<0.075}100{else}95{endif} (you can check this when a model is printing, by choosing the settings menu, and looking at the FLOW setting...)

as a test, to see if it improves your surface finish, you can change the flow value to a lower value, and if this is successful, you can change the extrusion modifier in slicer and save the modified profile for future use.

good luck, Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Nozzle catch

just a thought, is the STL available somewhere?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Nozzle catch

just a thought, is the STL available somewhere?

regards Joan

Aha, figured out quote.

I got the STL from Thingiverse. The URL is https://www.thingiverse.com/thing:3153866/files and the file in question is second from the bottom (the one with the Ecological in the title).

I don't think I can attach the STL to a forum post.

Re: Nozzle catch

How I wash my PEI sheet:

I do NOT use a scrubber sponge, especially the ones for pans, they are way too aggressive for me. Plus, they too often get used for other things (like scrubbing pans) and collect all sorts of stuff that gets transferred to the sheet (experience speaking). Paper towels are cheap insurance there are no fabric softeners, skin softeners, or any thing else that will detract from adhesion.

Hot Water wash: often, as needed

Handle the bed only by the edges.

Wash the bed in hot water, use a fresh paper towel as a wash cloth, with a few drops of plain dish soap (Dawn, unscented, no anti-bacterial, etc.). Rinse well in hot water - if you have very soft water, rinse a bit longer.

Dry the bed with a fresh paper towel.

Handle the bed only by the edges.

Place bed on printer.

Alcohol rinse: every few prints

Once in a while, an alcohol rinse is helpful to remove PLA residue. It does not remove finger oils.

Pour a 5 cm puddle of 91%+ alcohol in the middle of the bed, with clean hands use a fresh paper towel to scrub the bed. Wipe up all the alcohol.

Streak test: when contamination is suspected and after a wash

With a fresh piece of paper towel, and very clean fingers, dampen the towel with 91%+ alcohol, and wipe the bed side to side moving back to front, like you're painting it with alcohol. The alcohol should be thin enough on the towel it quickly evaporates. If you see any streaks, the bed is dirty and needs a wash.

Acetone wash: infrequent

Pour a 2 cm puddle of acetone on the bed, scrub it around with a fresh paper towel. It will evaporate fast as you clean. This step removes PEI oxides that form over time and with heat, and improves PLA adhesion to a like new state.

Regarding soap vs detergent: it requires a chemist to tell the difference: both are widely used surfactants to help water wet surfaces and mix with contaminants. PEI is not affected by most consumer soaps and detergents.

fyi @Joan, Scotch-Brite here in the states is essentially sand paper on a sponge - not something to recommend; we have a non-scratch bluish colored variety - but even they are questionable on soft PEI. Here's from 3M:

7448 - Light Grey, called Ultra Fine Hand - (600-800) 800 grit. 7440 - Tan pad, called Heavy Duty Hand Pad - (120-150) 60(?) Blue Scotch-Brite is considered to be about 1000 grit. (The value inside the parentheses is directly from 3M.)

And yes, I've destroyed Chrome faucets with the darn things.

@margaret.v: Place the STL into a .ZIP folder, they upload pretty well.

Re: Nozzle catch

Language is a funny thing.

Tell me about it.

So, yes. I see that the technical Canadian English term is dishwashing liquid, Canadian French translates to dishwashing detergent and we informally call it dish soap in our neck of the woods. I'll try the scrub pads and lower the extrusion.

I have read the Life Adjust Z and used it. I posted some pics on a forum post ( https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/first-layer-woes-t29057.html ). The two tokens look less disparate when I orient them the same way.

Re: Nozzle catch

Attempt to load zip

Re: Nozzle catch

You can also ZIP then upload the gcode file you are printing. That has all the settings being used (if sliced in Slic3r PE) ...

Re: Nozzle catch

Thank you guys,

Thank you Margaret.

I am away till Monday, so can't currently test print for you,

Maybe one of the other guys on here could give it a try, and if they succeed, share their G code with you... so you can try and recreate their successful print...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Nozzle catch

Thank you guys,

Thank you Margaret.

I am away till Monday, so can't currently test print for you,

Maybe one of the other guys on here could give it a try, and if they succeed, share their G code with you... so you can try and recreate their successful print...

regards Joan

Happy Easter Weekend Joan; and I'll try to print the token and post a photo: have a rather long print going right now, so it'll be tomorrow.

Re: Nozzle catch

Thanks Tim,

Happy Easter weekend to you too

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Nozzle catch

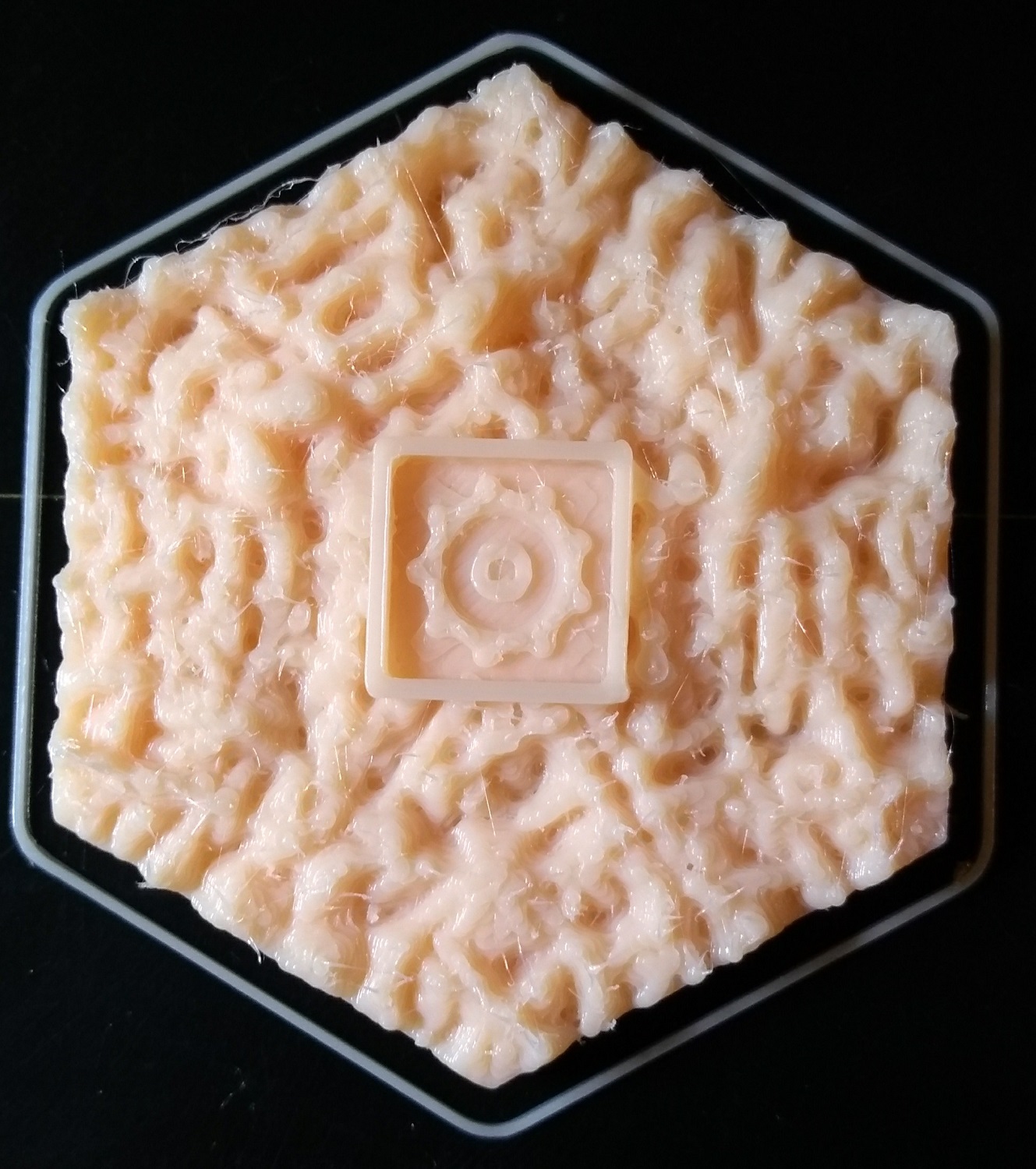

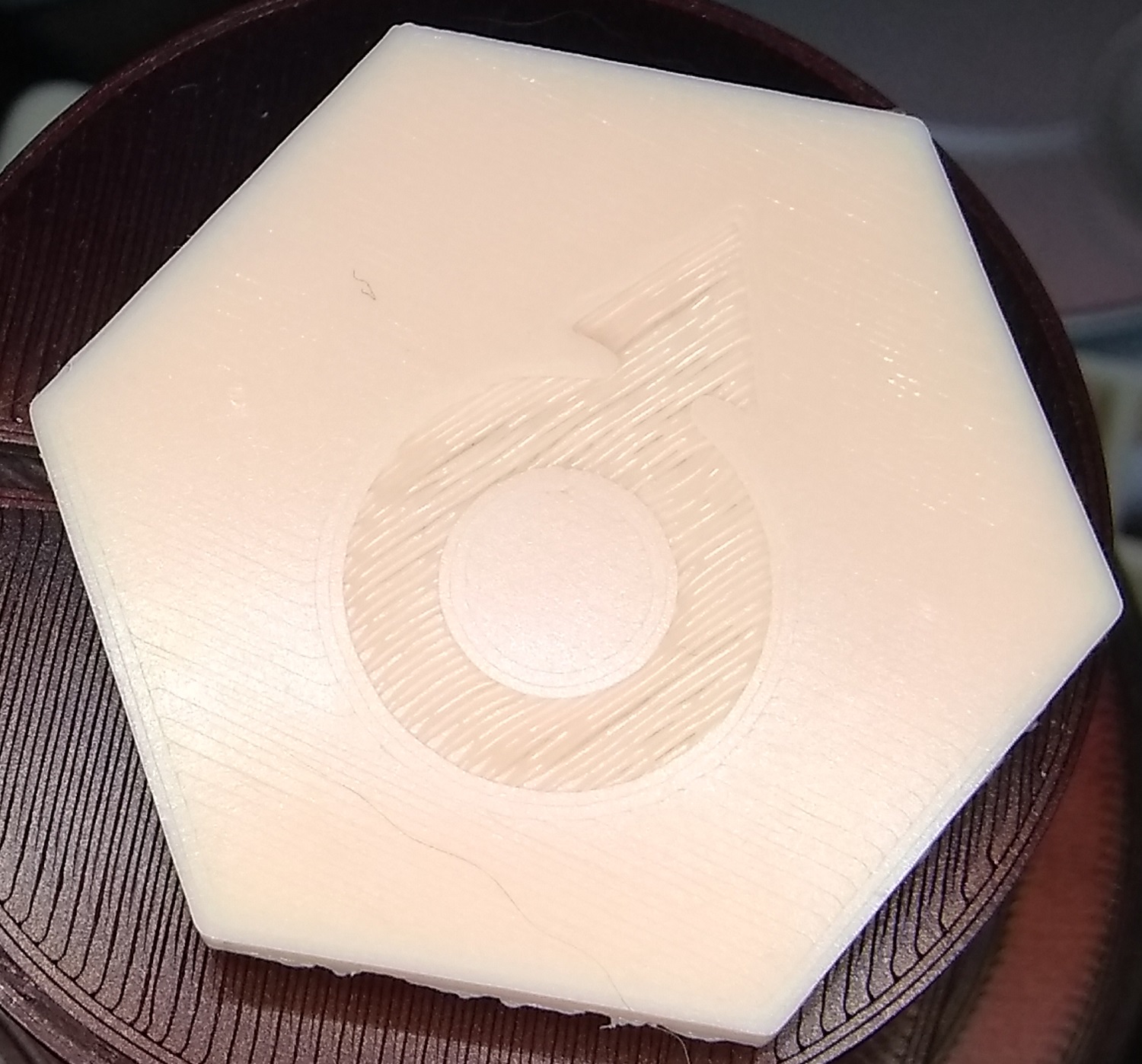

Finished the tokens ...

I used default 0.15 mm layers, Prusa PLA, and my low ooze Mk3 profile,. Filament is 3D Solutech beige. I did not enable bridge detection, but that might help the clarity of the bottom logo. My Layer-1 is a bit low, I get minor elephant foot, but that's how I normally run things. Gcode attached below images.

ps: All the peaks in the model make it a prime candidate for a heat gun pass...

RE: Nozzle catch

Thank you both for your help, suggestions and print test. I was also busy over the Easter weekend and just now got my forum credentials set up. (Although why my picture of my soap is a duplicate of the tokens is a mystery).

I lightly scrubbed the bed with a Scotch-brite China/Glass pad and Dawn, rinsed, and dried with clean paper towels. I printed out Tim's g-code and the token printed no problem and looks very nice. Optimistically I rubbed the bed with some 99% alcohol and started a 2.5 hour print of a 28mm figure at the standard 0.05mm settings except the filament was set to .95.

The first layer went down without a hitch but, at hour 1.5 and a bit I noticed that the corners of the base were starting to curl and lift. It went for another 10 minutes or so before it popped off the bed. The base was about 2.5cm square with a little extra filament for the support columns.

The figure is supposed to have writing on the bottom (the best way to describe it is an upside down cake pan) so perhaps the base was too thin. I plan to orient the object differently, add a brim and reprint it tomorrow. Hopefully the added surface, slower flow and super clean bed will help.

RE: Nozzle catch

PS Tim, when the print started it did more than my 3x3 then diagonal thing. Why did yours do more touches?

RE: Nozzle catch

PS Tim, when the print started it did more than my 3x3 then diagonal thing. Why did yours do more touches?

The 3.7 firmware offers 7x7 bed levelling and 1 to 5 measurements per point. It's worth upgrading.

RE: Nozzle catch

Thanks. I flipped the machine to 7x7. Read this again and switched the Z nr to 5.