Model peeling off the table during printing

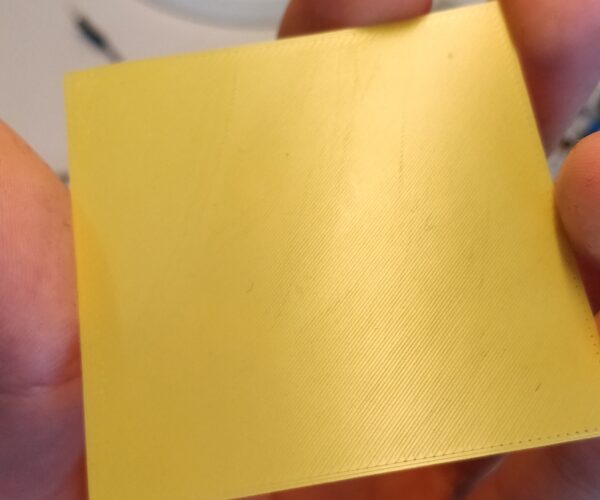

Hello, I have had my printer for four months and during this time I have not encountered any printing problems until now. The problems started to appear after the printer was recalibrated. I had a problem with the quality of the first layer and I think it still leaves a lot to be desired. The photo below shows the current state of the first layer during the test with 60x60mm square. By measuring the layer with a digital caliper, I obtained a result of 0.20 mm. The Z adjust is equal to: -1.230.

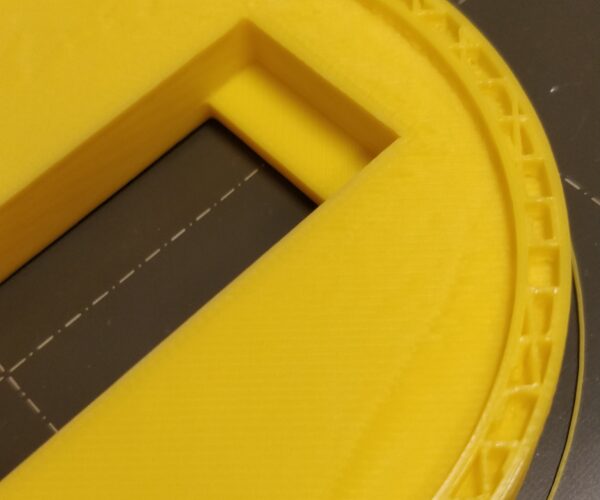

After the above calibration, I ran a larger printout. While observing the first layer, I noticed that there were smaller gaps in it, but I did not stop printing. When the printout reached the point where the walls of the element are printed, I noticed that the printout was partially detached from the table, which can be seen in the photo below (Click on the image to see full resolution).

Additionally, some irregularities and bulges appeared on the print surface.

In addition, you can observe the protruding edge along the contour of the detail at the time of transition from printing the base to printing the walls.

After noticing the above-mentioned imperfections, I canceled the printout.

So far I have tried:

- first layer calibration

- cleaning the nozzle

- cleaning the bed with soap and water (I clean the table with isopropyl alcohol before each print)

- reduction of speed when printing the first layer

I would like to ask for help in solving this problem or any suggestions on what I could do to improve the quality of printing.

RE: Model peeling off the table during printing

Well, warping happens... especially for large objects.

Assuming Live Z is well calibrated and the steel sheet is clean (using hot water and fragrant-free dish washing soap), here are a few approaches that have worked for me:

* Slow down print speed.

* Add Mickey Mouse ears to the corners. You can add a cylindrical part in PrusaSlicer, maybe 10mm diameter, change height to single layer height, then place the part at the corner. Repeat for each corner.

* Add a brim around the model, 5 mm or more. Wider or 2 -layer high brims may be needed but may not work with the size of the model or may require being added in your CAD software.

* Use Layerneer Bed Weld (< https://www.amazon.com/Printer-Adhesive-Layerneer-Original-Filament/dp/B079984GV5/> ). You only need a thin layer.

* If you have design control over your part and it's possible considering the intended use, you can try to round the edges and/or add holes to the base of the model.

* Combination of above. Usually, brim/ears does the job, or some Layerneer if needed, but large, rectangular objects can be a challenge.

You have clearly thought about most of these ideas already, my next step would be to add a brim.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Model peeling off the table during printing

Thank you for your reply. I would like to add that I was able to print the same part shown in the photos two months ago without any problems. Nevertheless, I will start my tests by adding the brim you suggested.

RE: Model peeling off the table during printing

I was able to print the same part shown in the photos two months ago without any problems

Very possible, not surprising. Could be subtle differences in ambient temperatures and drafts. 3D printing is still closer to voodoo than science...

I have a large model that I print regularly, and I have seen all degrees of warping, from none to what-the-heck. Printing it in an enclosure (even with doors open) has helped a lot, in the end I decided to print it with a brim every time, just not to risk anything.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/