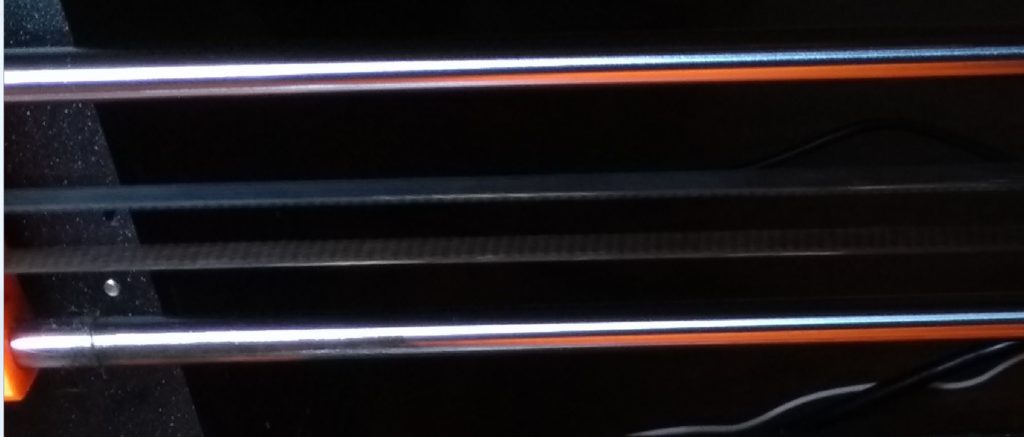

MK3 X-axis rod/bearing spacing & wear

Does anyone have a cure for the spacing differential in the X-Axis rod spacing at the ends (the two support frames) and the extruder bearing mounts? In my MK3 the extruder spacing is quite a bit different than the two supports, and causes the lower rod to bow slightly, which wears the bearings and seals prematurely.

One option is to redesign or somehow print the three parts oriented such that the rod spacing is better controlled - all in one print axis, controlled by layers - so the three parts are exactly the same. But somehow that seems like a lot of work.

Another option is to rout out the extruder housing so the lower bearing floats to auto-align with the rod spacing. Should work if I ensure fore-aft motion is constrained (Y-torque); X torque should be handled by the two upper bearings.

Thoughts and ideas?

ps: photo isn't perfect, but the lower rod is pretty scuffed up from the bearings being too tight at the two ends, and the lower grease seal is now leaking like a sieve.

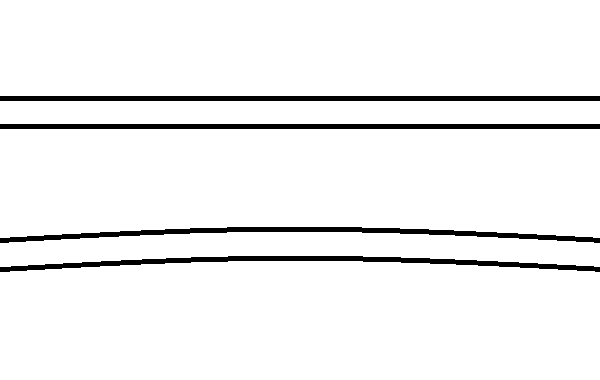

Rods look something like this exaggeration: