Leaking Nozzle

After switching to a new filament I began experiencing a leak between my nozzle and heat block on my mk3s kit. I have switched filaments plenty of times and this never happened before. After removing the front part of the extruder, it seems that a blob of filament melted and got stuck between the heat sink and the heat block. I have tried changing the nozzle and cleaning all of the filament in the extruder. Prints are still coming out alright, but filament slowly leaks out the top of the nozzle. I've looked at other posts on the forum but can't figure out whether this has to do with the extruder assembly or maybe my printer is over extruding during the print. Any help is appreciated.

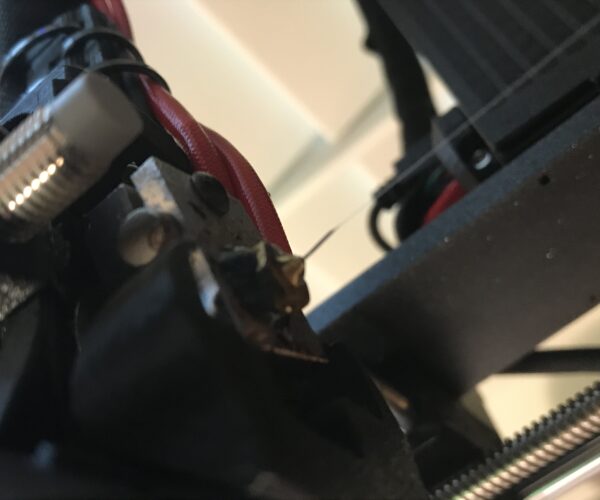

This is the PETG between the heatsink and heat block

The actual blob on the nozzle

RE: Leaking Nozzle

huntern08,

My first guess is that the nozzle is not properly tightened (careful - finger tight is correct) against the heatbreak inside the block. I suggest:

* **Stop Printing** - this will only get worse - unless of course you are trying for the biggest hotend blob ever prize 🙂

* Check E3D website for correct hot end assembly and the hot tightening procedure - that said I have experienced better reliability using 1/2 turn distance between the bottom of the block and the top of the nozzle when the nozzle is fully finger tight against the heatbreak inside the block. I think that E3d recommends 1/4 turn. Work you way through the process, it is not that scary once we have done it one or twice. Please be careful not to burn yourself on nozzles, blocks, spanners and hex sockets, etc - I have done that more than once, it hurts! If your nozzle is tight against the heatblock before it is tight against the heatbreak inside the block then in will leak via the nozzle thread.

* I keep notes for myself (I swap nozzles almost daily) where I can find them: https://digbatblog.blogspot.com/

* I am now careful about the bends and route of my heater and thermister wires to the heater block - I gently tie wrap these and have a slight curve to the hotend to help prevent hot end rotation. The hot assembly can rotate inside the extruder body and over time, and with a less than correct hot assembly procedures, the heatbreak may rotate within the block. Eventually the interface between heatbreak and the top of the nozzle thread will separate and filament will then start to leak. This is more likely if we swap nozzles.

Looking at the size of the blob (so far :-> ) I think that you could get it off the nozzle by just heating up to the correct material (PLA, PETG, whatever) temperature and picking off the blob with pliers, and cleaning up the bottom of the block with a wire brush - **be careful with the heater and thermister wires, these are fragile, yes fragile**. Then attend to why there is a leak and attend to the hotend.

Cheers

digbat

TANSTAAFL

RE: Leaking Nozzle

huntern08,

Another thought (I can't see how to edit my previous post) - It could just be filament up there and that there is no leak - after you clean the blob away you will be able to see where the nozzle is relative to the block and to check if it is properly tight - please do not burn yourself.

Cheers

digbat

TANSTAAFL

RE: Leaking Nozzle

When trying to remove PETG, don't take it all the way up to 230 Deg, but at 140 /150 the PETG is soft enough to pull away in one piece and soft enough to tear / pull apart.

At huntern08, do you do a cold pull before changing nozzles?. If not, may I recommend you do.

How I do a nozzle change whilst using PETG or any other filament that is not PLA which almost guarantees I can't get any filament stuck inside on the mating faces.

Unload the PETG and purge the rest out with cleaning filament / floss.

Load some PLA in until it has purged the cleaning filament out, then switch off the heat.

Slacken the bondtech drive (This is where a skelestruder is much better since I can simply lift the drive off against the spring without having to undo anything).

When the temperature drops to 80 Deg C, pull out the filament.

You now have a clean and empty nozzle and heatbreak with no filament which can get in the way when changing nozzles.

If you shine a bright light at the bottom of the nozzle you can see the internal reflection through the extruder when looking down from above and a nice round hole at the bottom - OK a dot!.

It may take a few extra minutes every time, but at least it means you have less possibility of things going wrong later, also since the nozzle is now clean, if you have a USB microscope, you can thoroughly inspect it for wear / damage.

Oh and finally, if your printing with PETG, then you should really look at using a nickel plated copper nozzle as the PETG doesn't stick to it unlike brass where it welds itself to it. If you have PETG stuck to the top of the brass nozzle at the mating face, you may not be able to get all of it off without scraping and you risk damaging the mating surface which could lead to another leak.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Leaking Nozzle

I appreciate the fast responses guys, I've just been really busy lately. Using a brass brush, I've been able to clean the nozzle off pretty easily when it's heated. However, the plastic keeps leaking again once I start printing. I tried adjusting the nozzle's tightness, but that didn't help. Im beginning to think that just reassembling the whole hotend might be the best idea. If I were to do this, where would I start and how can I remove it safely from the extruder body? Also once I disassemble it, what should I be looking for that could cause a leak?

RE: Leaking Nozzle

Just an idea:

What you could do to make sure the mating faces are true and close together, once you have everything apart and clean, use a candle, and stick the end of the heatbreak into the flame so it gets sooted up and the face is black, should only take a second, then assemble back into the heater block and screw the nozzle in from the other side and tighten everything finger tight.

The nozzle should either rub all the soot off the end of the heatbreak, or leave a shiny imprint in the soot where it has sat flush, if you are still left with a section that is matt black, then the two faces are not parallel so will not seal against each other.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Leaking Nozzle

Disassembling the complete hot end ideally you need to remove the thermistor and heater, whilst I found the thermistor came out easily, the heater did not and I ended up damaging the aluminium block trying to get it out, but I was replacing my block with a nickel plated copper block anyway, so it did not really matter, but you may be prudent to buy spares before you start, the thermistor wires are quite easy to break, and for that matter so are the heater wires if your not careful.

Maybe someone whom has found a simple way of getting the heater out can post a reply?.

Oh, and if removing the heatbreak, you will need some heatsink compound to reassemble it back into the V6 heatsink.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Leaking Nozzle

@chocki

I just ran into this situation and did, in fact, break off the heater wires, noob stuff I suppose. I did, however, get the heater out of the housing without any strife at all.

I used a rework station blower at 285º heating up the heater block and once it was hot enough I firmly unscrewed the screw holding the heater. Put a new one into place and there was no trouble there. I did run into a couple of gotchas though.

Even after tightening up the nozzle and the heat break together I still got some leakage, but I redid the routine and that worked out okay. The problem came on a follow-up print, halfway through the print, the ungodly brown blob. Again I thought that the error was on my part, on the assembly, but the heat block was clear of any residue. I noticed a wide swing of temperatures during the print, causing my filament to get too hot many times during the print causing a build-up of material around the nozzle. Finally, I got out the book, e3d procedures where they state, a PID calibration must be performed after changing the heater. I ran the procedure twice and finally got the temperature to remain practically rock solid throughout the print.

Happily, I got a perfect first layer with some very picky filament, Sunlu PLA+. The part is smooth as a baby's behind on the part the touches the bed as well as the top layer.

I was down two-day waiting parts and an afternoon clearing my errors after putting it all together

Regards,

Phil

Stay safe and healthy, Phil

RE: Leaking Nozzle

Did you assemble, bring the temperature up to 280 Deg C and then tighten the nozzle further whilst at temperature?

This is the way it is supposed to be done unless! you have a nickel plated copper heat block and are using nickel plated copper nozzles, then there is no need for this further hot tightening. These are the instructions provided by E3d and I can confirm I did not carry out a hot tightening procedure on my Nickel plated heater block and nozzles, and it does not leak!. I am also using the E3d titanium heat break.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Leaking Nozzle

Hi,

I did indeed heat and twist at 280, outside of the extruder, I just didn't do it right the first time. Finally, taking the entire assembly apart and cleaning the material off, first at 145º with the blower and then reassembly.

I was thinking of having an extra heat break and heater block on hand for when I do get a failure, so thanks for the advice I was looking at the titanium heat break, but the nickle and copper heater block sounds like the deal.

Stay safe and healthy, Phil

RE: Leaking Nozzle

[...] I was thinking of having an extra heat break and heater block on hand for when I do get a failure, so thanks for the advice I was looking at the titanium heat break, but the nickle and copper heater block sounds like the deal.

Having suffered through a stripped heater block, I can recommend having spares on hand:

- Thermistor

- Heater cartridge

- Heater block

- Heatbreak

- Nozzle

Depending on how fastidious you are in keeping your nozzle and heater block clean, removal of any or all of these parts may be difficult without damaging something else. My thermistor and heater cartridge were welded into the heater block I learned on. After replacement, I used appropriate high-temp thermal paste for the parts inserted into the heater block, and use a silicone sock to avoid crud building up.

While I had mine torn down, I substituted a titanium heat break and coated copper heater block. Don't forget the thermal paste at the top of the heatbreak (and only the top).

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Leaking Nozzle

@bobstro

Doesn't the silicon sock come off at times?

On my previous printer the sock would come off crashing into the model I was printing, which was painful. I like the cleanliness that the stock provides though. With this printer configuration, does the sock maintain its position?

Phil

Stay safe and healthy, Phil

RE: Leaking Nozzle

@chocki

Thank you for bringing this up, I continued to have a leak again. I know now that if there's a more than usual smell coming from the printer following any maintenance, the cause will likely be a loose hotend.

I followed the process as best I could, after cleaning the plastic that oozed out between the heat break and the heater block. Before I did that I cleared the threads within the heater block that were filled with plastic. By threading the nozzle at both ends until there was no more debris that was keeping me from getting an accurate cold seal.

I didn't realize that the ptfe tube had some minor damage at the end of it until I did a cold pull and saw the distortion on the filament end. After a cold pull the end should match the inside of the nozzle only, without any peaks pointing out.

I'll know by the end of the day if I finally get it all straight.

Phil

Stay safe and healthy, Phil

RE: Leaking Nozzle

[...] Doesn't the silicon sock come off at times?

It certainly can. After a few prints, they tend to sag. Fortunately, the fix is easy. Use a bit of wire twisted around the sock (avoiding the wires) to create a "retainer" (or "garter" as someone named it) to keep the top from sagging. Since trying this out over a year ago, I've had no issues with socks falling off or causing jams. The socks do crumble so need replacement every couple of months, but they're definitely in my "must use" category now.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Leaking Nozzle

Great, I'll order the spares and include some socks, since I change nozzles I'll probably go through them more often.

BTW, been printing 10 hours, no smells, blobs, or signs of leakage.

Phil

Stay safe and healthy, Phil

RE: Leaking Nozzle

Ugh I have been having the same issue. Two in row. I think part of the issue is there nothing for heat sink section to mechanically register in the hotend when loosing the heater block to change the nozzle. I don't particularly want to disassemble the extruder each time I want to change the nozzle but it seems like that may be the only reliable way other than playing roulette with whether or not it leaks. Already cost me a thermistor and heater, several failed prints and probably 6 hours of my life.

RE: Leaking Nozzle

It’s pretty easy really with practice, you get an adjustable spanner and use that to grip the heat block and stop it turning while you undo the nozzle with a socket wrench. Change your nozzle and reverse the procedure to tighten. The heat block and heat sink don’t move at all that way and assuming you are using proper e3d nozzles like the originals recalibration is easy as the difference is minor.

about the only bit you need to remove is the parts fan shroud as that makes it easier to get to the heat block, which is 1 screw.

RE: Leaking Nozzle

@theycallmejohn

"I don't particularly want to disassemble the extruder each time I want to change the nozzle..."

You don't have to disassemble the extruder to change the nozzle. You need a 16 mm wrench to fix the heater block and a 7 mm socket wrench to loosen the nozzle.

I'm using a self-developed CarbonPEEK (E3D V6) counter-holder instead of the 16mm wrench:

heat-resistant and firm up to 280 degrees celsius. Nothing will be scratched and no wires (thermistor, heatercartridge) will break.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Leaking Nozzle

@karl-herbert

I've been changing nozzles following e3d recommended procedure. Always tightening the nozzle with the temperature as close to 285° as possible. No leaking so far. Looking at the filament following a cold pull will give one an excellent clue as to the proper tightness of the nozzle. If the nozzle is not mated properly the filament end above the nozzle impression will have a protrusion, that is how I ensure proper tighteness. That way I also ensure an uncontaminated nozzle for my next print. Practice makes for perfection, getting the most out of an excellent printer is my goal. I suffered a lot with another printer unable to correct problems that are inevitable when printing 3d. Good luck developing your own process, perfect it. You'll get there, I was there which forced me to develop a process that works every time.

- Phil

Stay safe and healthy, Phil

RE: Leaking Nozzle

I'm using a self-developed CarbonPEEK (E3D V6) counter-holder instead of the 16mm wrench:

That is a pretty cool wrench! I found one of my dads old 5/8" wrenches (15.875 mm) which seems to be a better fit than my 16 mm wrench (which i haven't been using) going forward I will this wrench. Also ordered a small socket wrench for the nozzle.