It really pains me to say this

I have had my MK3S for about 3 months, i loved it so much that I ordered another. I have run about 5000M of filament through it and have been overwhelmingly satisfied with it.

The majority of my prints are terrain and buildings for my DnD group...i keep it printing almost 24x7.

My rant here is with the powder coated plate. I order this because I wanted to print some PETG stuff, mask straps , pi cases, dashcam holder for my car etc...

The sheet is absolutely not suitable for PLA printing, even though it is advertised as such. I have tried so many combinations of bed temps and nozzle temps...cleaned it so many different ways. I cannot get a consistent result with PLA. There is almost always an adhesion issue. I thought i had it solved with bumping the bed temp +10 degrees, and that worked for about 8 prints, but after that and after a thorough cleaning, the same adhesion problems came back.

This happens with all brands of PLA - hatchbox, esun, matterhackers - even genuine prusament...

I have cleaned my bed six ways from Sunday, ran numerous calibration files....done a temp calibration, disassembled my hot end and cleaned it thoroughly, tried different first layer speeds...etc.etc...

I suppose i could have gotten a bad sheet, but i just get the feeling this doesn't work consistently for PLA.

I've gone back to the original steel smooth sheet and things are working fine again. It just seems a shame, especially given the wonderfully open nature of this company. that the powder coat is advertised to work with PLA when it definitely does not.

I still love you guys Prusa, but please either fix this sheet or modify the description!

RE: It really pains me to say this

Good Morning Thomas,

you didn't manage to tell us how you clean the textured plate.

I wash mine with Dish soap and hot water, and rinse with hot water then Dry immediately with plain paper towels, and use immediately.

This is PLA with minimal bed contact on textured build plate Mk3 Printer

this is PLA on a different textured build plate with a mk2 MMU2 build plate

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: It really pains me to say this

Wash plate with dish soap, and a perfect 1 layer is important, both are needed for sticking to the bed.

Small parts or big flat parts I use glue stick, this is for the pei steel sheet. For powder coated I need to test in the future.

Extra and normally not needed:

First layer extruder, more heat.

Bed more heat.

And of course first layer slower to 10 mm.

RE: It really pains me to say this

How to calibrate first layer.

RE: It really pains me to say this

To clean my textured beds, I have started using green sponges that are more plant based. Scotch-Brite Greener Clean work very well. The key is a scratch free like you used for coated pans. I used Dawn Dish soap in the US.

--------------------

Chuck H

3D Printer Review Blog

RE: It really pains me to say this

Sorry I haven't replied soon to this, thank you all for your suggestions. I should have been more clear, I have thoroughly cleaned and adjusted the first layer.

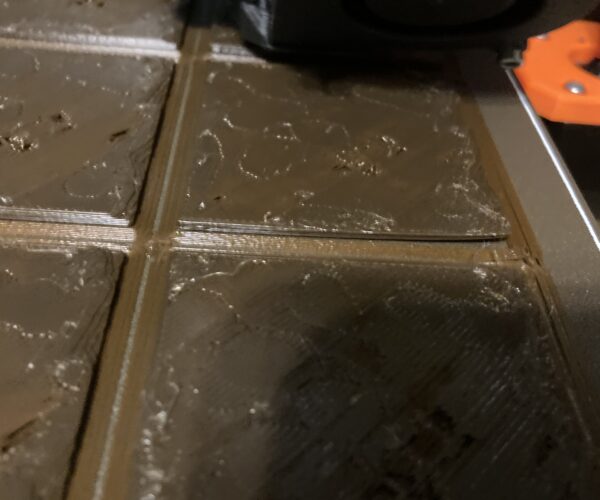

I wanted to get together some picture evidence of one of the issues I am experiencing.

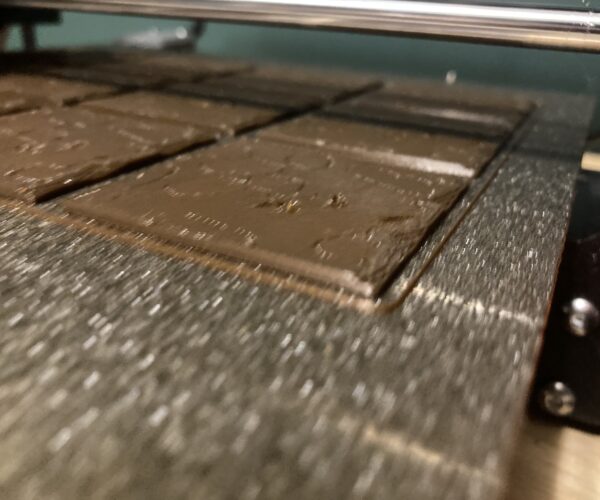

Below are the results of my latest print, some tiles for RPG use. This is just the latest failure I've had using the powder coat sheet that works fine on the smooth sheet. Others include larger single piece modules , smaller pieced toward the center of the plate not adhering at some portion on the first layer, or coming unstuck.

First , I thoroughly cleaned the plate. Hot water and dawn dish soap, dried with a new paper towel. Wearing glove the entire time. Next I put it on the printer and heated it to 85C for 10 mins to make sure it was good and dry.

Next I sprayed and wiped with Windex, and finished it off with one more cleaning of 99% IPA. Changing paper towels between each application and wipe off. I wore gloves the entire time so there was no danger of oils getting on the plate.

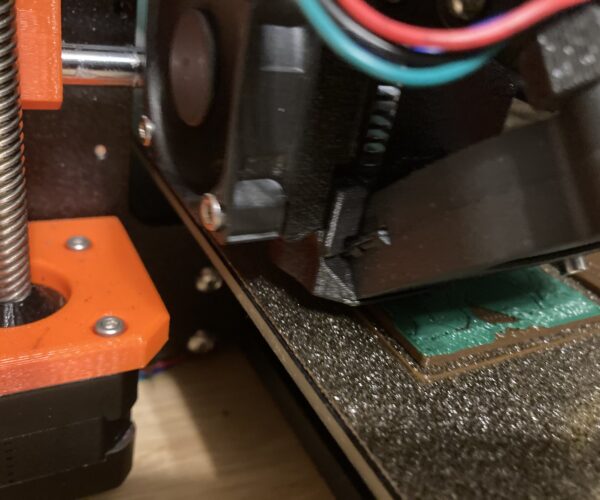

I calibrated the first layer as seen below and I don't think I can get it much better than this

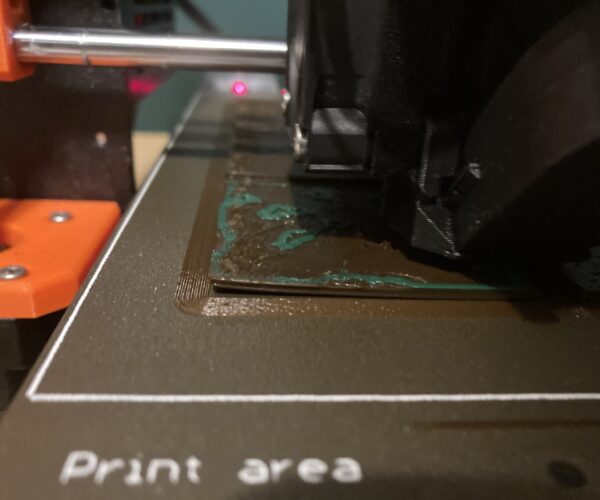

Next I loaded up a set of tiles that i print quite often, first layer seemed to go down ok, but about 2 hours into it, the tiles closest to the edge started to detach from the plate and warp.

I printed a brim on this batch in hopes of preventing the curl...no luck

Waited for the color change and as you can see the problem spread to tiles on the other side, nearest the edge

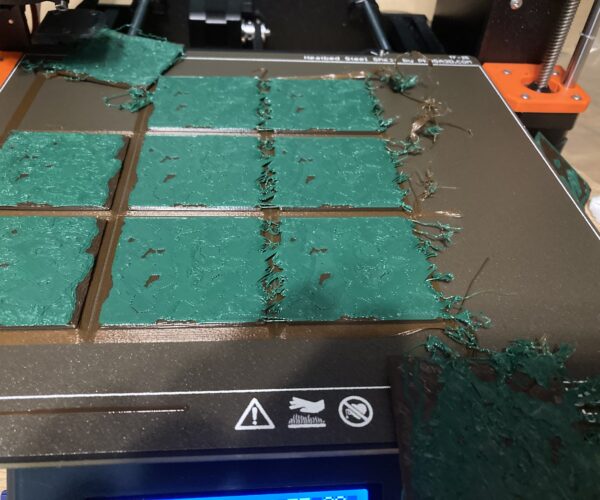

At this point it was getting late and i thought to just let it run and check on it in the morning....As expected here's the mess i woke up to -

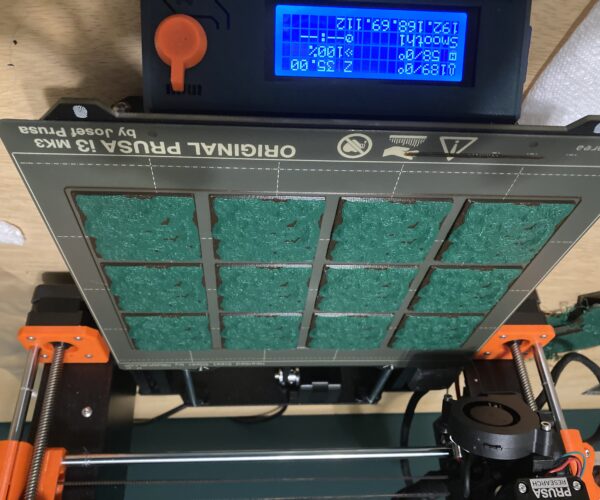

Now i did the same print again, with the normal smooth sheet , same cleaning and calibration procedures and came out with this -

No curl or pulling away at all..

I really like the texture of the powder coated sheet and i it's a shame I can't get it to work reliably with PLA.

Any other suggestions?

RE: It really pains me to say this

What are you trying to print?

--------------------

Chuck H

3D Printer Review Blog

RE: It really pains me to say this

Do you mean the object? The are landscape tiles for tabletop RPG. It's essential that they print flat as they need to be glued to a base, which is another thing i cannot print on the powder sheet to to adhesion issues.

This is the model, but it's been trimmed and edited to suit my needs. https://www.thingiverse.com/thing:1658155

If you mean material, it's PLA.

RE: It really pains me to say this

Another call-out for this product. (I'm sure some of you are getting tired of this.) 😉

The Layerneer Bed Weld really helps with the curling-up in the corners with PLA on the textured sheet. I'm in the habit of putting a dab of it where each corner will be when I print a flat PLA piece. It also works well for small-footprint supports and as a release agent for PETg and ABS.

RE: It really pains me to say this

@jsw

I have to agree. If you need a link: Layerneer Bed Weld from Amazon.

--------------------

Chuck H

3D Printer Review Blog

RE: It really pains me to say this

3rd party TheKKIINGG textured sheet has been everything the Prusa textured sheet was advertised as. Works great with PLA with just a Dawn dunk.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: It really pains me to say this

3rd party TheKKIINGG textured sheet has been everything the Prusa textured sheet was advertised as. Works great with PLA with just a Dawn dunk.

I ordered the matterhackers one earlier this week and will do a side by side comparison when it arrives. If that doesn't work out for me I'll give the other a shot. Thanks!

RE: It really pains me to say this

@thomas-k-reed

Your cleaning , what sheet are you using?

You are cleaning with dish soap, wipe with windows cleaner, then clean with alcohol, clean with alcohol is not needed, and this is for the pei sheet.

The powder coated sheet clean with dish soap, and the print on it. Nothing else is needed.

Most important is :

Clean bed,

first layer must be 100%.

Often is lower z layer a better sticking of part.

If filament is not good, or your settings are not good:

First layer slower to 10 mm,

first layer print hotter 10 C,

Bed 10 C hotter.

Powder coated bed, pla printing works if not your settings are not good, I just stated printing on powder coated bed, and pla works.

Warping, keep cold air/wind from bed, put a box or something around the printer,

Print hotter or colder you can try, try different filament.

Use glue stick,

First layer 100% and clean bed.

RE: It really pains me to say this

For warping use a big brim, it should attach to the model.

RE: It really pains me to say this

Worth noting is AFTER cleaning with soap and water - Windex (a release agent) and then Alcohol (a grease dispersant) were used. So a perfectly clean bed was recontaminated before use.

Soap and hot water - then stop cleaning - because the bed is as clean as it's going to get .

RE: It really pains me to say this

@tim-m30

I assure you I have tried every combination of cleaning possible over the last 3 weeks and the results are the same.

RE: It really pains me to say this

I recommend a chat with support.

Another option, as mentioned above, try theKKIINNGG PEI coated Sheet. It is available on Amazon in the US.

--------------------

Chuck H

3D Printer Review Blog

RE: It really pains me to say this

And more than one person has trashed the textured sheet due to poor PLA adhesion. I purchased the one Bob mentioned above. Not much use with it so no opinion, but it has a much better reputation than Prusa's.

RE: It really pains me to say this

I recommend a chat with support.

Another option, as mentioned above, try theKKIINNGG PEI coated Sheet. It is available on Amazon in the US.

This is the one Bob mentioned above. The first two versions were not as good, btu V4 is great.

--------------------

Chuck H

3D Printer Review Blog

RE: It really pains me to say this

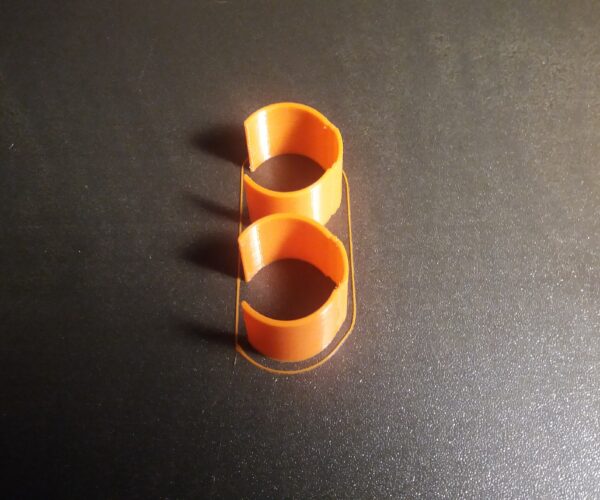

My other sheet arrived today and it's night and day...adhesion is great, no glue sticks, other adhesion potions or voodoo required.

As promised here's the comparison between the matter hackers sheet i ordered -

Same print at the point where it began to peel away last run, no curling at all -

Completed print, flat on plate -

Comparison of the textured bottom between the matter hackers plate and the Prusa plate - nearly identical...the Prusa has a little finer texture.

I hate to trash prusa's product on their forums but I think the potential buyer's have a right to an honest comparison, and this is just my opinion, so do with it what you will.

I have a second MK3S coming on Monday and have ordered a theKKIINNGG sheet to use with it for comparison.

I want to stress that I have been overwhelmingly happy with the MK3S , Prusa's support and the community. This is the only gripe i have since becoming a customer.

Thanks all for taking the time to comment and respond, your suggestions were appreciated.