Inconsistent bed adhesion while maintaining first layer calibration

Greetings, all.

For a few months now, I've had some pretty good luck printing on the MK3S+ kit. Recently, I started having issues with bed adhesion and decided to perform a calibration wizard. After completing this, I conducted the first layer calibration using the Prusa logo from the included SD.

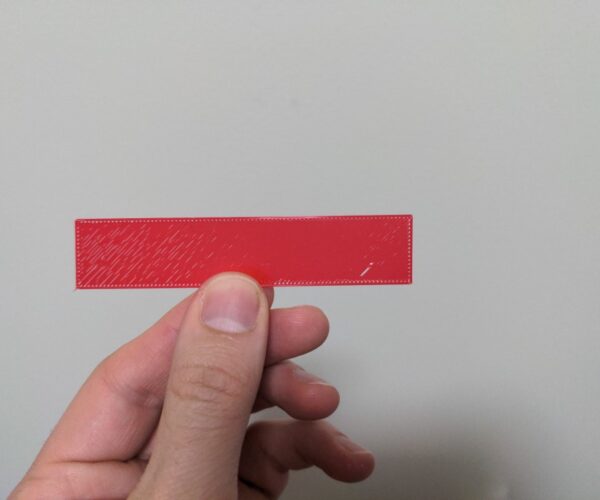

The first round looked like this, and the z-adjust was at -1.750 for the whole print. I thought it was weird that it was so inconsistent from one side to the other.

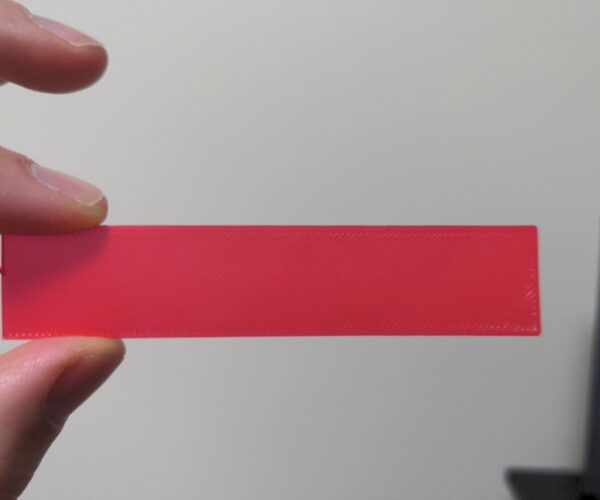

I continued reducing the z-adjust until I got to what I thought was a somewhat decent result at -1.820.

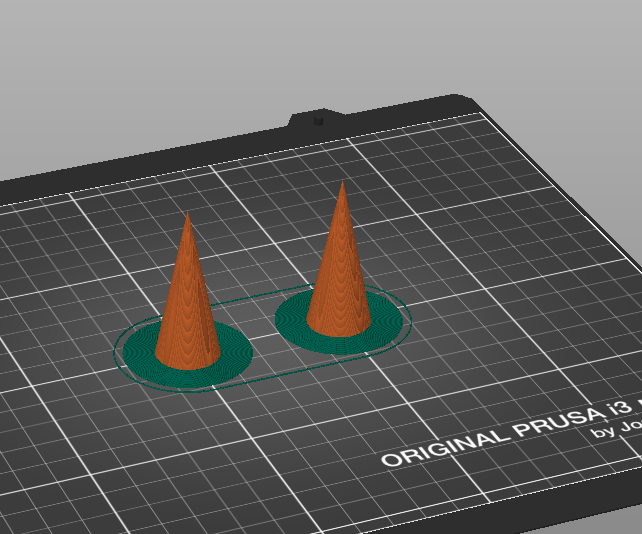

Below is a screenshot of a simple model using Prusa Slicer shapes that I used for testing when I was having some issues with stringing and blobbing.

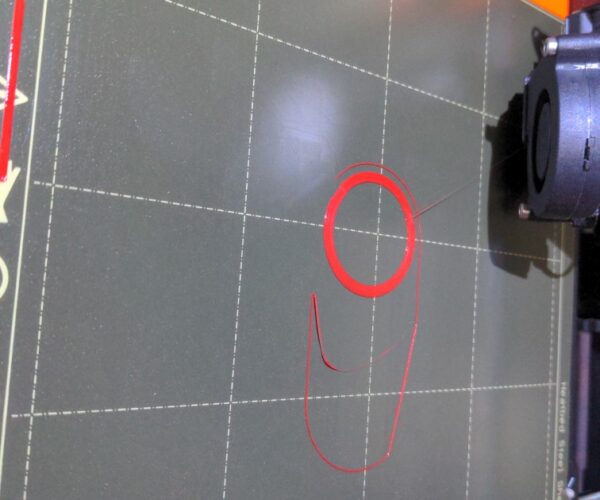

I tried printing this after the first layer calibration, and immediately had the below bed adhesion issues with the skirt and brim.

I continued to lower the live z-adjust on a few subsequent prints. Each time I lowered, the brim and skirt adhered a bit better. I was able to get the skirt and brim to adhere to the bed at about -1.960. But the nozzle ended up being so low that it dug into the adjacent PLA like this.

A trough is also visible in the initial purging, further indicating (I think) that the nozzle is too low.

Additional measures I've taken include cleaning the steel sheet with soap and water followed by 70% isopropyl alcohol wipedown, drying the filament for 6 hours at 45C, using different filament rolls (including different brands), and replacing the nozzle (using the official instructions and a 1.5Nm torque wrench). I'm using Prusa PLA filament on the PLA temperature setting.

My thought is that there is some warping on the steel sheet, and I need to replace it. Looking at the first image, there is such a drastic difference in first layer calibration from one side to the other. The problematic bed locations on the Prusa logo print also seem to be the same as the two-cone print's skirt problem locations.

Before I put money into a new steel sheet, I'm looking forward to any insight I might get from others here. Hopefully there is something else to try.

Thoughts?

Dan.

RE: Inconsistent bed adhesion while maintaining first layer calibration

https://help.prusa3d.com/article/bed-level-correction_2267

Cheerio,

RE: Inconsistent bed adhesion while maintaining first layer calibration

First of all you don't mention if you are using 3x3 or 7x7 mesh levelling. 7x7 is better as it gives a more detailed mesh. Obviously 49 points is going to take bed variances into account better than just 9 points.

Secondly, the mesh levelling process is temperature dependent. The following picture isn't mine but it perfectly expresses the fact -

The process from a cold start to a warm start can be completely different.