Heatsink&Nozzle Leakage

Hi

me as a MK3S-owner asking:

I recently encountered having Heatsink and Nozzle Leakage for the first time.

I don't know how to master that issue - seen videos and took it as a manual, but I didn't succeed so far...

One question in advance:

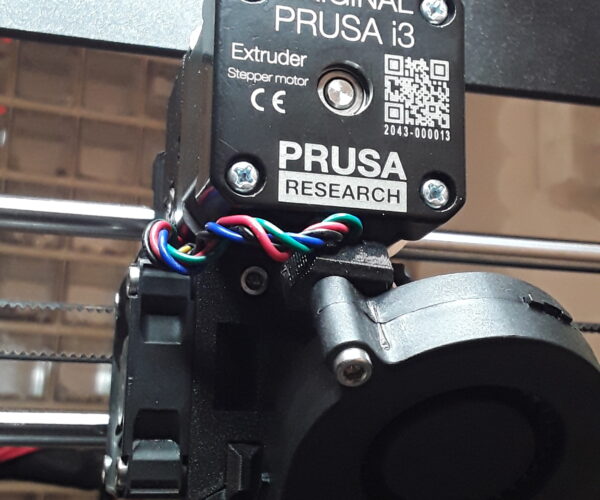

I suspect to have the "E3D V6 Hotend for Prusa", right?

Is/was there a PTFE-washer between heatbreak and nozzle? Couldnt find any information on that.

As far as I twice - unmounted everything and cleaned a great mess, I haven't really succeed getting it tight.

For every help very thankful.

Best Answer by Lichtjaeger:

I assume the problem is layer-time. The previous layer has not had enough time to cool down and gets pushed by the next layer.

Try to add more objects to the print job so the hot nozzle is not constantly above the plastic that should cool down.

You also might want to look into the cooling settings in your Slicer. (Especially the layer times.)

RE: Heatsink&Nozzle Leakage

One more thing...

Is it possible I damaged something already and... is that possible?

Are alternative heatbreaks more sturdy or tight?

After not having success getting it tight so far, I'm a bit worried what to do...

Hi

me as a MK3S-owner asking:

I recently encountered having Heatsink and Nozzle Leakage for the first time.

I don't know how to master that issue - seen videos and took it as a manual, but I didn't succeed so far...

One question in advance:

I suspect to have the "E3D V6 Hotend for Prusa", right?

Is/was there a PTFE-washer between heatbreak and nozzle? Couldnt find any information on that.

As far as I twice - unmounted everything and cleaned a great mess, I haven't really succeed getting it tight.

For every help very thankful.

RE: Heatsink&Nozzle Leakage

Google: "prusa mk3s replace heatbreak"

-first result will give you this.

[Mini+] [MK3S+BEAR]

RE: Heatsink&Nozzle Leakage

I think I did all this, but my collet is broken and I tried without.

I can't find any for a reasonable price... Is it really that important?

Do you know where to buy collects for under 1 euro a piece? At prusa I'd pay about 3,50 for that little thing PLUS shipping!

Google: "prusa mk3s replace heatbreak"

-first result will give you this.

RE:

Yeah indeed. I mean that thing

... would you buy a coffee if it costs not 3 quid but 14??

RE: Heatsink&Nozzle Leakage

Okay, I managed to get the tube out and put it back in (without collet) and reassembled all...

The heatbreak is counter-screwed against the nozzle, then I heated up the block as told and again, tightened the nozzle while the heatblock was frizzling. Hope to have a tight fit now

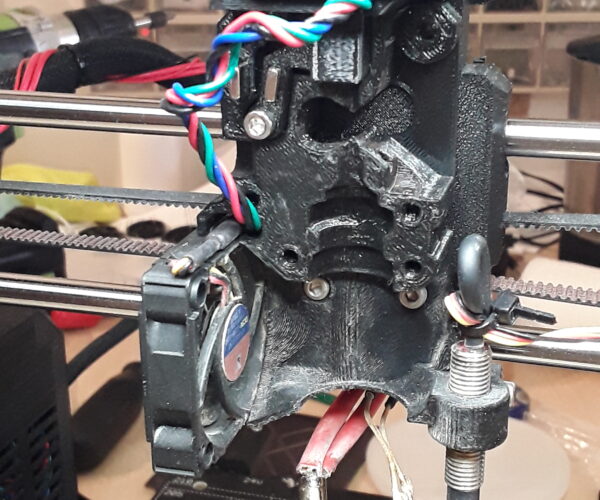

Problems printing after cleaned and reassembled hotend V6

I don't know what to do, as nothing works any more really.

It all started with leakage...

I was sure, I reassembled right, tightened everything and added thermal conducting paste to the 3ED V6...

The former thread, called somewhat Leakage isn't actual I fear... unless nothings leaking anymore, but can be found here

This is are the visual results. What's wrong? I am sure to have same CAM running over and over again. Same, before the reassembly was perfectly fine. Look:

Did I maybe trashed the threads of the Hotend after reassembling it 6 times in a row now?

I'm very very frustrated

RE: Heatsink&Nozzle Leakage

So, I reassembled the cleaned out hotend - as documented. As told, I don't use any collet.

Did you think about why collet is needed for PTFE in first place? I mean, without a collet, you shouldn't be surprised with result. Just purchase few collets (and maybe some other cheap spare parts you might need in future -for shipment to be worth paying) and wait patiently until you get them.

[Mini+] [MK3S+BEAR]

RE:

So it is about the collet?

You sound like an angry father without explaining much, but to me I can't understand in the first place, why 3 TPFE-tubes are in for free when purchasing a MK3S, but there's no collet.

Have you seen the prices at Prusa, Mister? And you don't get em on 3djake nor rest of Europe

RE: Heatsink&Nozzle Leakage

And before you treating like your little poopy son, Mister Bogdan - here:

So, I reassembled the cleaned out hotend - as documented. As told, I don't use any collet.

Did you think about why collet is needed for PTFE in first place? I mean, without a collet, you shouldn't be surprised with result. Just purchase few collets (and maybe some other cheap spare parts you might need in future -for shipment to be worth paying) and wait patiently until you get them.

RE: Heatsink&Nozzle Leakage

So, I reassembled the cleaned out hotend - as documented. As told, I don't use any collet.

Did you think about why collet is needed for PTFE in first place? I mean, without a collet, you shouldn't be surprised with result. Just purchase few collets (and maybe some other cheap spare parts you might need in future -for shipment to be worth paying) and wait patiently until you get them.

Please, If you'd take your time to give me a full answer. So I understand it by logic.

Your *this and that* I can't understand, with all due respect.

I looked up every printing problem - this doesn't show up. Nearest would be overextruding.

RE: Heatsink&Nozzle Leakage

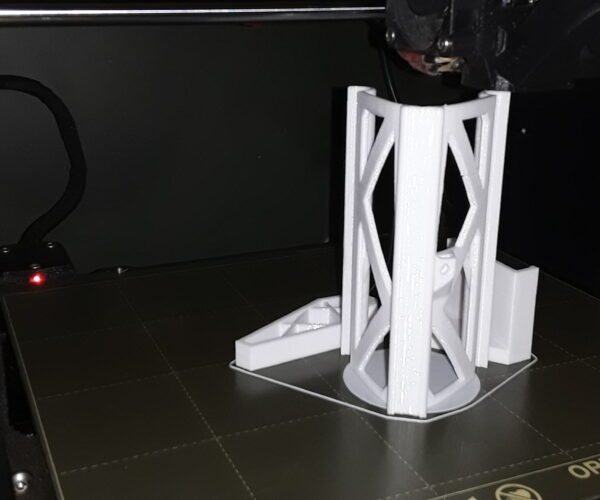

I assume the problem is layer-time. The previous layer has not had enough time to cool down and gets pushed by the next layer.

Try to add more objects to the print job so the hot nozzle is not constantly above the plastic that should cool down.

You also might want to look into the cooling settings in your Slicer. (Especially the layer times.)

RE: Heatsink&Nozzle Leakage

Did you think about why collet is needed for PTFE in first place? I mean, without a collet, you shouldn't be surprised with result

So far, I did some prints without a collet. I'm not saying a collet is a non-necessity BUT... the results aren't too shabby for saving 12 Euros NOT buying one to replace my broken one.

A nice lad in the German Prusa Forum hand me over a link for reproducing a collet on my printer.... BTW.

The results:

RE: Heatsink&Nozzle Leakage

I'm glad you managed to get printer working without collet -even I see that as temporary solution. Some explanation:

Collet isn't just something that closes the gap between PTFE tube and heatsink. It's main purpose is, to prevent PTFE tube move (vertically) out of heatsink. It is very important, that there's NO gap at the bottom of PTFE tube. That's also the reason why PTFE tube has chamfer at the bottom.

If you take closer look at collet, you can see that it has four metal blades inside:

When collet is inserted into heatsink, you can move PTFE tube up and down. But when you pull out the collet and fix it with clip, then blades prevent PTFE movement.

In short: you can print a collet imitation, but it's useless.

[Mini+] [MK3S+BEAR]