RE: Heatsink&Nozzle Leakage

Okay thank you for clarification.

I'm glad you managed to get printer working without collet -even I see that as temporary solution. Some explanation:

Collet isn't just something that closes the gap between PTFE tube and heatsink. It's main purpose is, to prevent PTFE tube move (vertically) out of heatsink. It is very important, that there's NO gap at the bottom of PTFE tube. That's also the reason why PTFE tube has chamfer at the bottom.

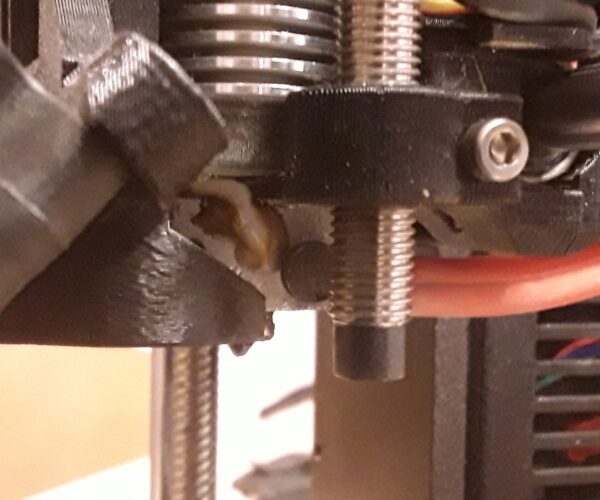

If you take closer look at collet, you can see that it has four metal blades inside:

When collet is inserted into heatsink, you can move PTFE tube up and down. But when you pull out the collet and fix it with clip, then blades prevent PTFE movement.

In short: you can print a collet imitation, but it's useless.

RE:

... was after my last hotend - assembly.

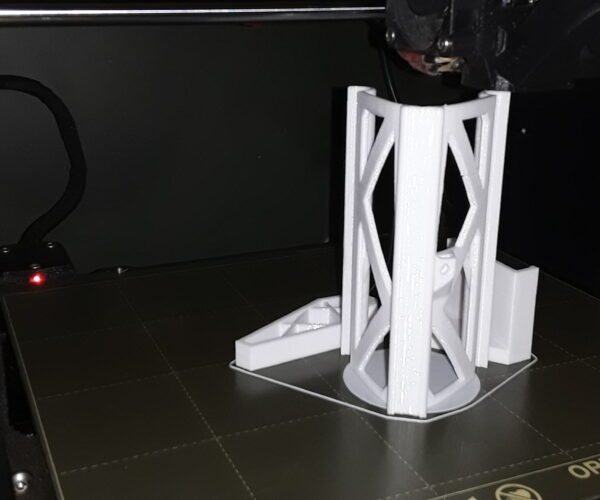

So, as it turned out my leakage wasn't fixed (again)... And it last about 54,3 (!) hours of printing after I'm sending you this photo:

- quite obvious the ooze building up...again.

So on question again:

Why?

I really double-thighten the nozzle and heatbreak around the hotend.

I'm printing at 262 Degrees. The nozzle was rethigtened at 285 Degrees - heating the the block for over 2 minutes...

Might it be, that some other failure exists? Loose threading on the heatblock maybe?

... thank you

RE:

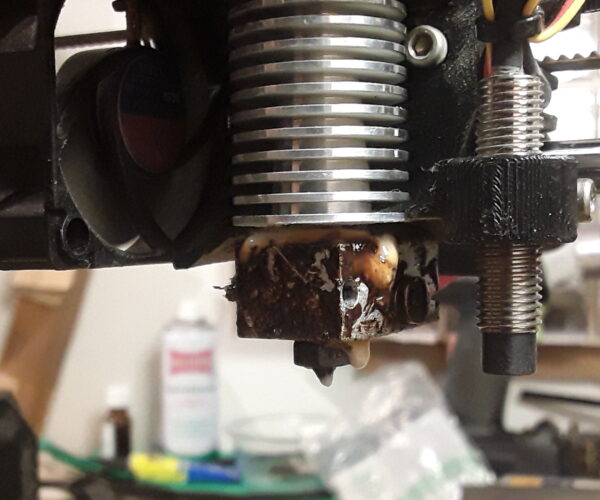

Maybe I'm looking at wrong place, but that thing on heater block (next to heater cartridge) looks like filament leakage to me. If filament is coming out at the top of heater block, then you didn't assembled hotend properly. Maybe you should check here again.

Maybe you should take a photo from back side -that way we could see the whole hotend.

[Mini+] [MK3S+BEAR]

RE: Heatsink&Nozzle Leakage

Please, read my complete thread - so, you'll understand what it is about and that I really read, learned and did everything! to undergo this problem.

Thank you very much.

Even if I'd be not clever enough to understand (which I doubt), I still am VERY motivated not to run into this leakage problem over and over again (- to this, please guys, read again - and you'll know its my 7th time now to repeatedly trying to fix an issue we'll known to me and how to fix).

Again.

Might it be the threading meanwhile got too much play? I DON'T understand.

Here the next photo:

(no, it's not fun)

RE:

As I deassembled everything now, I see -

leakage comes from both up and below...

... the PTFE-tube is fine

RE:

Please, read my complete thread - so, you'll understand what it is about and that I really read, learned and did everything! to undergo this problem.

Now you read my words: you did NOT assembled hotend properly.

Might it be the threading meanwhile got too much play? I DON'T understand.

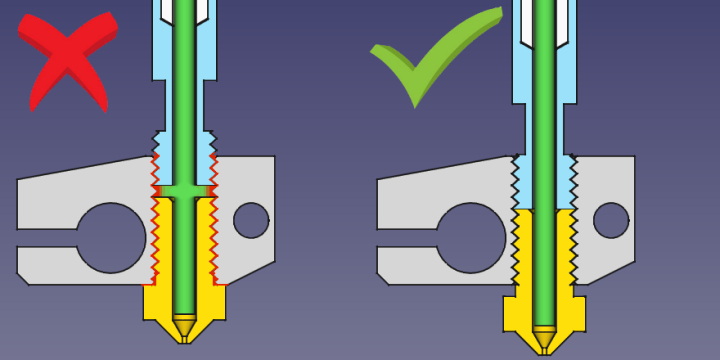

-yes, you don't understand. Threading has nothing to do with that at all. Threads function is not to prevent leakage -threads only keep parts together.

-as you can see on left image, if there is a gap between nozzle and heatbreak, then filament will escape (leak) trough threads. Nozzle must be tightened against heatbreak, so there's no gap. And that's why it's important that there's about 0.5mm distance between nozzle head and heater block (right image).

[Mini+] [MK3S+BEAR]