First layer issue with MK3S+ after upgrading from MK3S

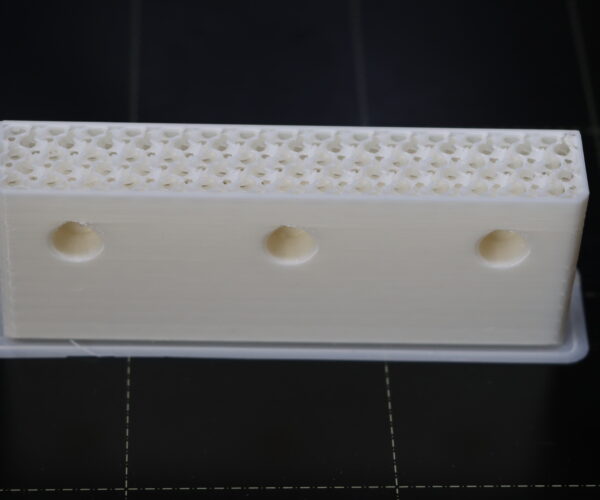

I have been using the MK3S for more than a year without any problems. But since I upgraded to the MK3S+, the printer does not seems to be stable anymore. It might not be related to the upgrade, but the one that I cannot figure out is this first layer that keep skipping (gap) in the initial pattern:

This is what I tried to fix the issues:

- I did several cold pull and made sure there was no clog

- I check that there was no resistance on the filament. The spool is just over the printer.

- I tightened the idler door (I tried different tension).

- I assumed this was caused by the the extruder that was skipping so I double check that Bondtech gear was properly aligned and not lose.

- I disassembled the extruder and made sure the PTFE tube was secure in place.

The first few layer of any prints is fine but I the infill seems to have gap (sounds familiar).

Any ideas where to look next?

Best Answer by Gregzy:

I confirm the issue was caused by the nozzle. Everything is working now. Thanks to JPLau001 and Xanthe for your help.

Things to check

Try the following:

- clean the print surface of the sheet with isopropyl alcohol and check that the surface is still flat. Oil or bumps in the print surface can cause skip issues in the first layer.

- check that the hotend is still firmly held in place in the e-axis part of the x-carriage and that the x-carriage itself does not wobble. You may have some loose screws leftover from your upgrade and your diagnosis work. Also check that your pinda/SuperPINDA probe is firmly held in its holder without any wobble or slipping.

- check the teeth on your Bondtech gears for any accumulated debris blocking the fine or large teeth and the tension on your extruder idler assembly; the screw head on the tensioning screw should be flush or near flush with the extruder body surface as per step 34 of the e-axis assembly guide ( https://help.prusa3d.com/en/guide/5-e-axis-assembly_169235).

- confirm that your printer has been upgraded to the latest firmware available for a MK3s+ (3.10.0 as of 27th September 2021).

- rerun z calibration. Also run first layer calibration for each steel sheet type you have as they each have different thicknesses.

- if possible use a micrometer or digital Vernier calliper to confirm that your filament has a consistent diameter over several meters and is cylindrical rather than oval in cross-section.

- run PID tuning on your hotend especially if you've changed or modified it. That will help it maintain its temperature better in its current state.

RE: Similar troubles here

I'm also having similar troubles since update from MK3S to MK3S+...

The 3.10.0 version has been released in last May 2021, not september 27 (!?)

After things to check, still in the dark of the printing gap source of the issue

Try the following:

- clean the print surface of the sheet with isopropyl alcohol and check that the surface is still flat. Oil or bumps in the print surface can cause skip issues in the first layer.

- check that the hotend is still firmly held in place in the e-axis part of the x-carriage and that the x-carriage itself does not wobble. You may have some loose screws leftover from your upgrade and your diagnosis work. Also check that your pinda/SuperPINDA probe is firmly held in its holder without any wobble or slipping.

- check the teeth on your Bondtech gears for any accumulated debris blocking the fine or large teeth and the tension on your extruder idler assembly; the screw head on the tensioning screw should be flush or near flush with the extruder body surface as per step 34 of the e-axis assembly guide ( https://help.prusa3d.com/en/guide/5-e-axis-assembly_169235).

- confirm that your printer has been upgraded to the latest firmware available for a MK3s+ (3.10.0 as of 27th September 2021).

- rerun z calibration. Also run first layer calibration for each steel sheet type you have as they each have different thicknesses.

- if possible use a micrometer or digital Vernier calliper to confirm that your filament has a consistent diameter over several meters and is cylindrical rather than oval in cross-section.

- run PID tuning on your hotend especially if you've changed or modified it. That will help it maintain its temperature better in its current state.

Hi,

Thank you for taking the time to reply to my post. These are all great advices. Here is my result going through your suggestions:

- I actually own 5 print surface and always clean them between prints with IPA. But just to make sure, I cleaned it this time with Acetone and also did a run after I wash a plate with dishwasher (Dawn Ultra is usually good at that). I also checked that the magnetic bed was clean. No change

- Yes, I checked that nothing was wobbling anywhere. I physically checked the hotend with my hands (of course it was cold 😉 ). The superPINDA is firmly in place with no movement and I recently recalibrated it. The x-carriage is ok too.

- There is no debris on my Bondtech gears and all the teeth seems to be in place. I even use a toothbrush to clean them anyway. This is the first place I looked. That the filament would slip would have been a logical explanation. The tension is also as per the assembly guide. I tried to release or increase the tension to see if it makes any differences.

- Yes, I confirmed that I use the firmware 3.10.0.

- I reran the z calibration. I am getting about the same dashed calibration line on every sheet whatever settings (of course if its too high it does not even make square corner).

- I used a digital caliper to confirm the filaments was consistent (around 1.75mm) and cylindrical. I actually tried with different spool from different vendor and different material. I mostly use Prusament.

- Yep, I ran the PID at 230.

After all these steps, I am still getting this calibration with gaps (and obviously any prints will fail like the second picture).

I think I will need to consider changing/ordering replacement components. I am thinking the problem might be with the Super PINDA, the bondtech gear, the nozzle and even the motor.

While everything checked out with the Super PINDA, I noticed few weeks ago my first layer calibration was changing. I assumed it was a loose PINDA, as you mentioned with item #2. I tightened the PINDA but it seemed to be getting worst and worst.

I am still trying to come up with a test that would confirm the source of the problem. I am sure it is something stupid, but just can't figure it out. You would thing I would be better I finding this kind of issues after more than 2 years oft almost continuous printing. 😋

Re: After things to check, still in the dark of the printing gap source of the issue

Further things to try:

Check that your Bondtech gear on the extruder motor is firmly in place and that the grub screw is tight against the flat part of the extruder motor shaft. This should stop any slop in extrusion.

Check the two small bearings in the bondtech idler gear for wear issues and that the idler gear door is not cracked or splitting near either the door pivot screw or the rod holding the bondtech idler gear.

Go into PrusaSlicer and temporarily modify the hotend print temperature settings for your filament up by about 5 degrees celcius and then reslice the objects to generate new gcode. See if that helps with the first layer skip in your first picture and the under extruded infill issues your seeing in the second picture.

RE: Similar troubles here

Firmware 3.10.0 may have been released in May 2021 but it was still the latest MK3S+ version released when I checked on 27th September 2021 my time (AEST UTC+10).

Maybe the problem is with the nozzle

Further things to try:

Check that your Bondtech gear on the extruder motor is firmly in place and that the grub screw is tight against the flat part of the extruder motor shaft. This should stop any slop in extrusion.

Check the two small bearings in the bondtech idler gear for wear issues and that the idler gear door is not cracked or splitting near either the door pivot screw or the rod holding the bondtech idler gear.

Go into PrusaSlicer and temporarily modify the hotend print temperature settings for your filament up by about 5 degrees celcius and then reslice the objects to generate new gcode. See if that helps with the first layer skip in your first picture and the under extruded infill issues your seeing in the second picture.

Hey Jplau001,

I did make some progress.

Thanks for the additional suggestion. Yes, I did double check that the Bondtech was firmly in place and grub screw was tight on the flat part of the motor shaft.

I did not notice any specific wear issue on the gears (I did order some replacement to swap it eventually). The plastic assembly does not show any sign of fatigue.

I was not able to change the temperature for the calibration (can it be done?) but I did make the test for my model with +5 degrees with no change in the end result.

You give me the idea to try to place a needle in the nozzle and wiggle around see if there was any obstructions.

To my great surprise, the next test went a lot better as you can tell from the following picture:

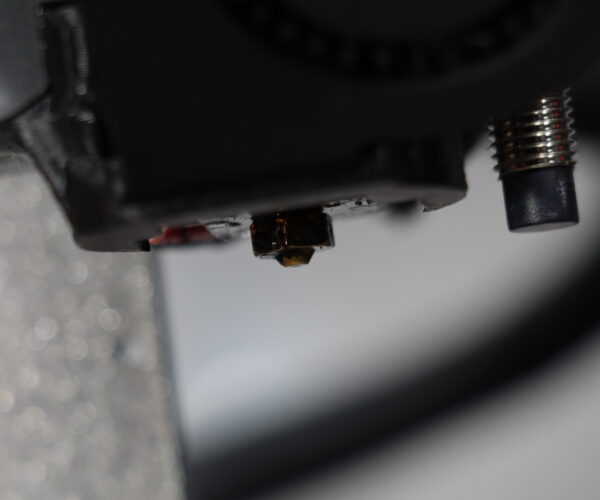

I am still having some inconstancy in my prints. Hey we are making progress! But I think my problem might be with the nozzle. I think my print quality could benefit from replacing it:

Is this just me or the nozzle is flatter than it should be?!?

Worn End

If that's an E3d 0.4mm nozzle, then it's badly worn!

Worn nozzle

If that's an E3d 0.4mm nozzle, then it's badly worn!

Yes it is a .04mm lol. I don't know what happened there. I have been using this nozzle for only 3 month. I'll replace it tonight.

Worn Nozzle

I confirm the issue was caused by the nozzle. Everything is working now. Thanks to JPLau001 and Xanthe for your help.