Filament stuck with 0.25 nozzle

Hi, I never had a filament stuck before with the standard 0,4 nozzle.

But two weeks ago I tried the wood/PLA so changed the nozzle to a new 0.6, and it worked fine.

Then printed som PETG with 0.6, worked fine for some hours but then there was i jam and the filament stepper motor started skipping. Started reading about it and trying out different ways the solve it but ended up with changing the PTFE-tube.

Then made som prints with 0.25 and 0.4 nozzle instead, with PLA, worked fine for 30+ hours at least.

Then yesterday I started a print with PLA and 0.25 nozzle, the filament got stuck on layer 2 or 3. Managed to disassemble PTFE-tubeto get it out, started again and it stuck on the same place. Managed to get it out just by turning the filament-stepper up and down, and then extruded a whole lot manually. Nothing stuck! Then started the print again with a brand new PLA, stuck on the same place 😤 got the filament out. Tried a new G-code but now with PETG and 0.25. Got up until layer 10 maybe and stuck again!! 😫

All filaments are the prusament except the wood-filament but it's the one from prusa webshop, and also the nozzles.After each jam I really made sure there are no blobs left, and that the PTFE-tube is mounted as it should, and then run a good amount of filament manueally through the extruder.

Wish I never started this nozzle-changing thing 😔 any ideas?

Best Answer by its3415:

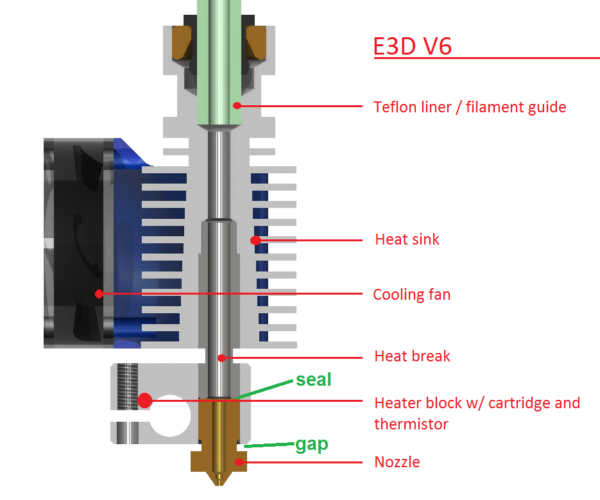

Firstly, if you are replacing your hotend, consider getting a standard E3D heatbrake, not the Prusa version with a wider 2mm diameter section just above the nozzle, which some people believe is the source of jams, and if you do swap out the heatbrake, make sure you use thermal paste on the thread between the heatbrake and the finned heatsink. (Be careful to be sparing with the paste, you don't want to contaminate your ptfe tube with thermal paste oozing off the thread as you tighten the heatbrake in.)

Make sure you follow the E3D instructions when changing the nozzle. Changing the nozzle with the hotend heated up is a lot more likely to produce a good seal between the nozzle and heatbrake. Mind your fingers, your spanners will get pretty warm...

One possibility for your problem would be slight overcooking of the filament. Your flow rate goes down when you swap to a 0.25mm nozzle, so the filament will be spending more time in the nozzle before being extruded. The cure for that is to slightly reduce the print temperature, or increase the printing speed.

Another possibility is that your PID needs to be calibrated; i.e. your nozzle temperature is fluctuating and sometimes going too high or low. If you add a sock to your heater block, then do a PID calibration from the printer menu, this should be improved. (Just doing a PID calibration from the printer menu *might* improve matters, without the addition of a sock).

Some filaments seem to be more likely to clog when they aren't dry, so it might be worth drying your filament in the oven at a low temperature. (50 to 60 degrees C) However, I've only really experienced this problem with pure PET (Note: *Not* PETG)

Finally, retraction can sometimes cause jams, with the filament cooling when it is retracted from the nozzle and then jamming as the extruder tries to push it back. Reducing retraction length in the slicer will cure this, although it might increase stringing or leave artifacts on the print where the nozzle moves away from the print.

Update

Update:

So kept on reading this article again

https://help.prusa3d.com/en/article/clogged-hotend_2008

and this

https://help.prusa3d.com/en/article/extrusion-problems-prevention_2027/

Think I have located the problem to be near the heatbreak. Because the PTFE-tube is always fine, and the heatblock/nozzle seems empty and fine. Tried a new first layer calibration and made sure it's not too close and causing the jam.

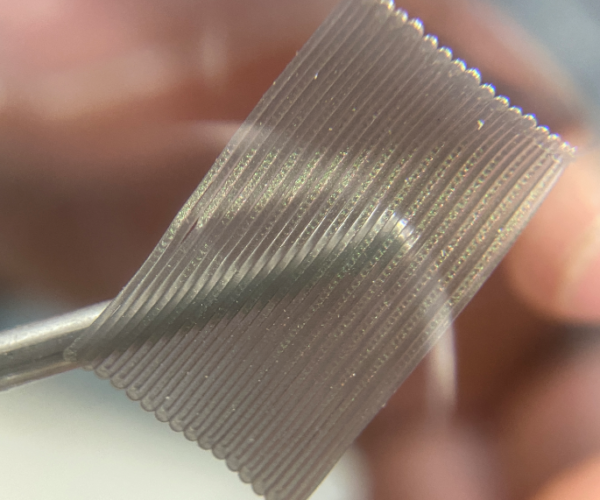

Looked like this after calibration with 0.25 nozzle:

Read something interesting in one of the articles above, that the nozzle should have a gap of 0,5mm to the heatblock. My 0.25 nozzle seemed to be all the way up against the heatblock, so turned it down 0,5mm but now it's "loose". It also says it should be in contact with the heatbreak inside? How to see that it is?

Anyway, the print failed just like before after the first layers.

Update 2

Okay, so I disassembled the entire hotend. Cleaned everything, I mean really clean. Then mounted back, with the nozzle 0,5mm from heaterblock and then made sure the heatbreak got in contact with nozzle when screwing back.

New calibration, got it even a bit higher his time. PLA runs through the 0.25 nozzle very nicely.

Then start a new print, this time with a different gcode (just a simple block 20x20x20). First layers works fine but when the infill should start the same problem occurs, no plastic comes out and it prints in the air. This time i solved it without taking the hotend apart, could just run the stepper up and down a bit and it came a nice stream of molten plastic again.

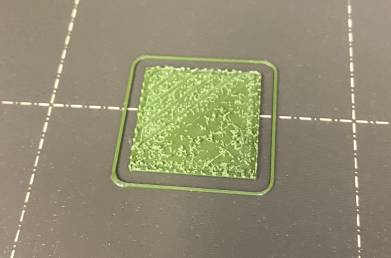

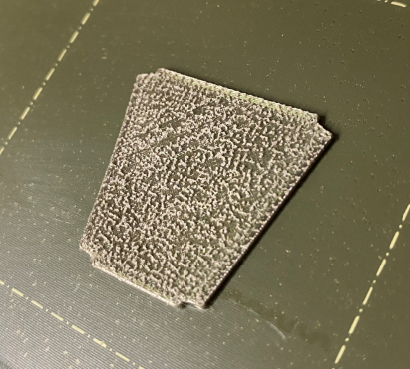

Looks like this:

And this:

I'll order a new hotend today but would be nice to know whats causing this.

RE: Filament stuck with 0.25 nozzle

Firstly, if you are replacing your hotend, consider getting a standard E3D heatbrake, not the Prusa version with a wider 2mm diameter section just above the nozzle, which some people believe is the source of jams, and if you do swap out the heatbrake, make sure you use thermal paste on the thread between the heatbrake and the finned heatsink. (Be careful to be sparing with the paste, you don't want to contaminate your ptfe tube with thermal paste oozing off the thread as you tighten the heatbrake in.)

Make sure you follow the E3D instructions when changing the nozzle. Changing the nozzle with the hotend heated up is a lot more likely to produce a good seal between the nozzle and heatbrake. Mind your fingers, your spanners will get pretty warm...

One possibility for your problem would be slight overcooking of the filament. Your flow rate goes down when you swap to a 0.25mm nozzle, so the filament will be spending more time in the nozzle before being extruded. The cure for that is to slightly reduce the print temperature, or increase the printing speed.

Another possibility is that your PID needs to be calibrated; i.e. your nozzle temperature is fluctuating and sometimes going too high or low. If you add a sock to your heater block, then do a PID calibration from the printer menu, this should be improved. (Just doing a PID calibration from the printer menu *might* improve matters, without the addition of a sock).

Some filaments seem to be more likely to clog when they aren't dry, so it might be worth drying your filament in the oven at a low temperature. (50 to 60 degrees C) However, I've only really experienced this problem with pure PET (Note: *Not* PETG)

Finally, retraction can sometimes cause jams, with the filament cooling when it is retracted from the nozzle and then jamming as the extruder tries to push it back. Reducing retraction length in the slicer will cure this, although it might increase stringing or leave artifacts on the print where the nozzle moves away from the print.

RE: Filament stuck with 0.25 nozzle

@its3415

Thank you very much for the answer.

I ordered a new hotend earlier today and added som extra stuff, like one more heatbreak and some PTFE-tubes etc. Do you recommend another heatbreak than the one in prusashop? https://shop.prusa3d.com/en/mk3mk3s/202-hotend-heatbreak-e3d-mk3s-mk25s-mmu2s.html I see in another store there is the E3D V6 Heatbreak original spare part, that's the one you mean?

Will test to do a PID calibration! Do you recommend using a sock all the time during print?

Overcooking, yes I thought of that too. Since the print is sliced with 0.05 ultradetail and the print itself is kind of small that could be worth a try.

It is possible that my filmanents are a bit moisty but the same thing happened when i opened up a brand new roll of prusament.

I did not change the retraction time manually, it's from the Prusaslicer (Mk3S 0.25 nozzle). One would think that the standard setting would be enough but I will try that too. A little bit of stringing is far better than this.

RE: Filament stuck with 0.25 nozzle

I bought my replacement parts direct from E3D in the UK. They sell Prusa and standard versions of the V6 extruder parts. I believe you have to keep the Prusa design of the heatbrake if you want to use an MMU, but I don't believe there's a benefit to using the Prusa specific heatbrake if you don't. I suspect the heatbrake in the prusa shop is the prusa specific one, but can't tell for sure.

However, I would suggest exhausting the other possibilities before replacing the heat brake.

I'm not 100% sure whether to recommend a sock. I use one and it improves matters on my printer.... Firstly, the sock means that failed prints resulting in blobs are a lot easier to clean off. Regarding temperature performance, I have a non-standard fan shroud which seems to improve part cooling a little, an E3D titanium heat brake and the E3D copper heater block, and for my configuration, the sock definitely improves temperature stability (in conjunction with a PID calibration, which I should probably have said should be done after any hotend part is changed, excluding nozzles if you are not changing the nozzle material.)

For info, the change to a titanium heatbrake was to reduce heat creep when printing hotter melting filaments, and it does seem to work, but I don't believe it makes a lot of difference for PLA or PETG. The copper heater block was a replacement for the standard part when I ended up with broken heater cartridge I couldn't get out of the original block, and the copper block wasn't much more in price at the time, so I decided to try one instead of the standard block.

RE: Filament stuck with 0.25 nozzle

@its3415

I ordered a new hotend from prusa and an extra heatbreak.

Also ordered an E3D standard heatbreak and a sock from another place.

While I'm waiting for the stuff I took the hotend apart (again) to see if there was any leakage, and there was! So now I will clean everything and then get the standard 0.4 nozzle back and see if I could get it running again.

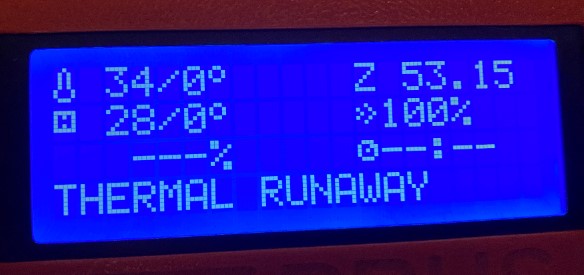

Before taking it apart I tried the PID calibration and it said thermal runaway the first time. Then it made the calibration 5 of 5 steps/times. Don't know if it did anything. I'll probably start that calibration again now after the cleaning.

RE: Filament stuck with 0.25 nozzle

Some success! 🤠 I printed a small cube 20x20x20 without any jamming or leakage. BUT it's with the standard 0.4 nozzle.. Do I dare to change to the 0.25 again? 🤔

RE: Filament stuck with 0.25 nozzle

Things you might find helpful next time:

I keep atleast one E3D V6 Hotend kit or E3D V6 Assembled Hotend sitting in the tool kit for rapid replacement. I order from Amazon for the Prime shipping, but you could order from Prusa if you have time and prefer.

I clean up the clogged or repair the hotend as needed with a clog repair kit and a heat gun.

--------------------

Chuck H

3D Printer Review Blog

RE: Filament stuck with 0.25 nozzle

@minestoff

With the printing of standard PLA and PETG there should be no problems with a 0.25 nozzle. It becomes more difficult with the wood- or carbon-based variants.

Make sure that you only use high quality nozzles, preferably E3D or similar (e.g. Tringlelab..).

You must also make sure that the nozzle seals well to heatbreak. The spring pressure for filament transport should also be adjusted.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Filament stuck with 0.25 nozzle

I made a try and switched to the 0.25 nozzle, this time I did it with E3D:s instructions: https://wiki.e3d-online.com/E3D_Nozzles And it worked! 🤓 The 0.25 print went on for +2hours and came out nearly perfect! I haven't compared the instructions from E3D with the ones from Prusa but I found the E3D very straight forward and easy to follow.

So to sum it up, one of the problems could have been leakage from the heatbreak/heatblock.

@charles-h13Great tip, and I did order the stuff during this so the will serve as spare parts. It's easy to think the printer is like a micro-wave, you press the knob and get back when it's finished. But it's more than that, it's a complicated thing to melt plastic with this kind of precision. Impressive it is.

@karl-herbert Do you have any tips for adjusting the spring pressure? It never crossed my mind before all this that it could be in different positions (I bought the pre-assembled Mk3s)

Thank you all for the help, it was learning!

RE: Filament stuck with 0.25 nozzle

@karl-herbert Do you have any tips for adjusting the spring pressure? It never crossed my mind before all this that it could be in different positions (I bought the pre-assembled Mk3s)

Thank you all for the help, it was learning!

Take a look at this post:

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.