Error M112

Hello,

Today I got this error when tying to print

Send: N600 G1 X143.938 Y79.144 E0.02211*95

Recv: ok

Send: N601 G1 X144.577 Y79.443 E0.02211*92

Recv: ok

Send: N602 M105*35

Recv: ok T:215.0 /215.0 B:57.7 /60.0 T0:215.0 /215.0 @:30 B@:127 P:40.0 A:38.7

Send: N603 G1 X145.156 Y79.848 E0.02215*91

Recv: ok

Send: N604 G1 X145.654 Y80.346 E0.02212*93

Recv: ok

Send: N605 G1 X146.059 Y80.925 E0.02215*92

Recv: ok

Send: N606 G1 X146.358 Y81.564 E0.02211*81

Recv: ok

Send: N607 G1 X146.540 Y82.245 E0.02211*88

Recv: Error:Temperature heated bed switched off. MINTEMP triggered !

Recv: // action:cancel

Changing monitoring state from "Printing" to "Error: Temperature heated bed switched off. MINTEMP triggered ! - // action:cancel"

Send: M112

Send: N608 M112*47

Send: N609 M104 T0 S0*46

Send: N610 M140 S0*98

Changing monitoring state from "Error: Temperature heated bed switched off. MINTEMP triggered ! - // action:cancel" to "Offline (Error: Temperature heated bed switched off. MINTEMP triggered ! - // action:cancel)"

Connection closed, closing down monitor

I upgraded to the latest firmware, but I got the same issue again.

I tried to do an"heatbed calibration", it failed with "Issue Err MINTEMP BED"

Any idea what first step I should do =?

RE: Error M112

Hello,

Today I got this error when tying to print

Send: N600 G1 X143.938 Y79.144 E0.02211*95

Recv: ok

Send: N601 G1 X144.577 Y79.443 E0.02211*92

Recv: ok

Send: N602 M105*35

Recv: ok T:215.0 /215.0 B:57.7 /60.0 T0:215.0 /215.0 @:30 B@:127 P:40.0 A:38.7

Send: N603 G1 X145.156 Y79.848 E0.02215*91

Recv: ok

Send: N604 G1 X145.654 Y80.346 E0.02212*93

Recv: ok

Send: N605 G1 X146.059 Y80.925 E0.02215*92

Recv: ok

Send: N606 G1 X146.358 Y81.564 E0.02211*81

Recv: ok

Send: N607 G1 X146.540 Y82.245 E0.02211*88

Recv: Error:Temperature heated bed switched off. MINTEMP triggered !

Recv: // action:cancel

Changing monitoring state from "Printing" to "Error: Temperature heated bed switched off. MINTEMP triggered ! - // action:cancel"

Send: M112

Send: N608 M112*47

Send: N609 M104 T0 S0*46

Send: N610 M140 S0*98

Changing monitoring state from "Error: Temperature heated bed switched off. MINTEMP triggered ! - // action:cancel" to "Offline (Error: Temperature heated bed switched off. MINTEMP triggered ! - // action:cancel)"

Connection closed, closing down monitor

I upgraded to the latest firmware, but I got the same issue again.

I tried to do an"heatbed calibration", it failed with "Issue Err MINTEMP BED"

Any idea what first step I should do =?

Are you printing in a cold environment or is there draught somewhere?

https://help.prusa3d.com/en/article/mintemp-and-mintemp-bed_2169

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Error M112

Hi,

I am printing in my company office, it is around 21-22 degree Celsius.

/Eric

RE: Error M112

Thanks,

The issue is with the thermistor, I will try to change the cable.

/Eric

RE: Error M112

I've been running into this as well, but only via OctoPrint (logs below). If I use the printer to preheat first then the bed warms up promptly and then I can start the print via OctoPrint without issues. So this leads me to believe it's not a hardware issue, but firmware or software?

MK3S, Firmware 3.9.3, PrusaSlicer 2.3.0, OctoPrint 1.5.2

Recv: T:215.21 E:0 B:30.7

Recv: // action:cancel

Cancelling on request of the printer...

Changing monitoring state from "Printing" to "Cancelling"

Recv: Error:Printer stopped due to errors. Fix the error and use M999 to restart. (Temperature is reset. Set it after restarting)

Changing monitoring state from "Cancelling" to "Error: Printer stopped due to errors. Fix the error and use M999 to restart. (Temperature is reset. Set it after restarting)"

Send: M112

RE: Error M112

@yvr76

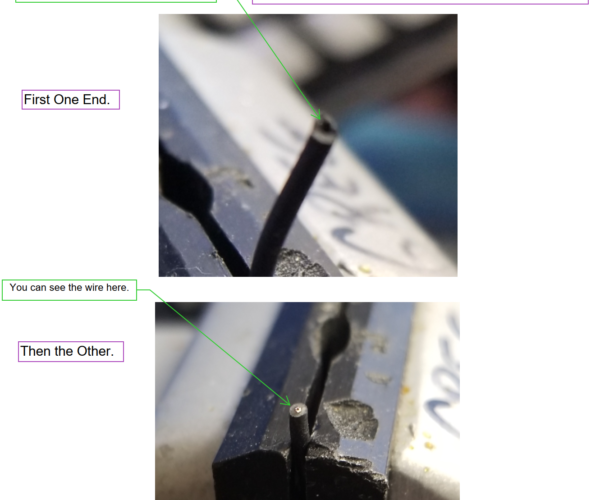

An intermittent open in the bed temp sensor wire can cause what you describe. I found my cable fault right at the plastic hood at the point where the cable attaches to the bed. This makes perfect sense because it would be a stress point as the bed moves back and forth.

I made this to show how to verify I found the problem. Intermittent opens and shorts can be a real pain to find. You can draw incorrect conclusions even using a multimeter or a TDR. This method, while a bit risky, does let you verify beyond all doubt that you found the problem.

So it's clear that I did in fact cut out the bad section. Now we just apply some solder and heat-shrink tube and we're back to printing!