Does MVS have a firmware component?

I have to produce a lot of large prints that I'd like to speed up as much as possible. I have moved to a 0.8 mm nozzle and 0.55 mm layer height, and the results are completely acceptable. But I'd like to speed it up even more so I started to explore limiting speed by MVS only.

So here's a question, mostly for my intellectual curiosity, that came to me as I was watching the model print this morning... What if I set speeds in PrusaSlicer that don't push the print to MVS and then ratchet up speed in the Tune menu on the controller? Will the firmware grab MVS from the gcode file and impose speed limits? Or will it just try to print as fast as possible, and potentially run into issues if MVS is exceeded? Does it even matter? What IF MVS is exceeded? Will it lead to clogs, other artifacts? Will the world come to an end?

Just curious to hear from folks who have thought about this a lot more than I have.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Does MVS have a firmware component?

I believe the firmware has no concept of MVS. It will just try and speed everything up.

Once you reach the max throughput of your hotend/filament combination then you are going to get skipped steps. This will of course lead to under extrusion/gaps in the output. If that's acceptable or not is up to you and the intended purpose of the printed items. A few areas with gaps might be ok. You could also get weaker spots though from the missed filament. Again, that might be acceptable to you.

I think the biggest danger is grinding filament away to the point where it stops feeding altogether as its not gripping it enough. Although not having tried maxing it out that much I don't know the likelihood of that. Bob's probably your best bet as I know he did lots of work in this area printing PPE.

RE: Does MVS have a firmware component?

@neophyl has it right, as usual. MVS is only a setting in the slicer. There is no firmware or printer-side throttling mechanism that I'm aware of. Unfortunately, spinning the front know speeds up all feed rates, so it's a heavy-handed approach.

There's no one trick to speeding up prints. A lot depends on the specific STL details. I've compiled a bunch of notes here. I'm in the process of adding more notes on extrusion width to wind up that series.

In short, though, I avoid trying to do much by spinning the front knob. I use it as an emergency override when something is amiss mid-print and that about it. It's just not repeatable.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Does MVS have a firmware component?

Thanks guys. It's what I expected. My thoughts were just wondered off into weird territory as I was watching the printer crank out filament at an ungodly speed . It came out actually quite well with all speeds set to zero, to have it bound by MVS. The only issue was some holes in the top layers but that's more caused by the sparse infill I'm using, which was borderline already using normal speeds. I'll give it another try with a bit more infill, which would still save me 25% of print time.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Does MVS have a firmware component?

I think one of Bob's speed up tricks was to set the extrusion width higher than normal for a nozzle. Depending on your print that can result in significant speed up printing as it would have to make a reduced number of passes for the perimeters. Its all highly model dependent though I guess. So printing 0.6mm perimeters with the 0.4 nozzle while leaving the external ones at 0.45 for example. Or even just setting the infill lines to be fatter with your reduced infill.

If you are printing loads of the same thing then it makes sense to spend a bit of time optimising that one thing at the start as the time savings will be worth it in the end. With your sparse infill near the top surfaces it may be worth adding a modifier to print a few mm with a higher infill rate just below those top layers so the rest can be as sparse as you want.

If the design isn't proprietary you could also post it and we can have an informal 'how optimised can we get this' competition 🙂 Sometimes stuff like that can be fun and are also good learning opportunities as you try stuff you wouldn't normally.

RE: Does MVS have a firmware component?

I think one of Bob's speed up tricks was to set the extrusion width higher than normal for a nozzle. Depending on your print that can result in significant speed up printing as it would have to make a reduced number of passes for the perimeters.

I've been doing a lot of experimentation with this lately. I don't have a notes page put together yet, but the main points are:

- Quality nozzles from E3D, P3-D, TriangleLabs and others have a wider collar around the nozzle opening that varies based on the size of the nozzle. On cheaper nozzle, this collar is the same size for all nozzle sizes. The purpose of that flat collar -- shown as the B dimension in the E3D nozzle drawings -- is to provide the squish necessary for good inter-layer adhesion.

- The exact ratio of collar-to-opening varies by nozzle size, but is at least 200% on all E3D nozzles.

- This means you can experiment using wider extrusion widths up to 200% of your nozzle size. This is really interesting when you have some smaller details that benefit from a smaller nozzle, but want to print wider to eliminate a perimeter if possible.

I'm hoping to get that notes page updated this week.

Its all highly model dependent though I guess. So printing 0.6mm perimeters with the 0.4 nozzle while leaving the external ones at 0.45 for example.

I've been printing some big chonky prints of tabletop scenery. Most of these are organic (irregular) shapes and just need to look good at 3 feet when painted, and be strong enough to be bumped about and handled regularly. I've found that I can get good results with ONE perimeter printing with a 0.6mm nozzle and a 1mm extrusion width. This saves a lot of print time.

Or even just setting the infill lines to be fatter with your reduced infill.

This one's interesting. My main use for infill is to support the top surfaces. It doesn't need to be strong so much as dense near the top. I'm experimenting using the Support Cubic infill pattern up to 12%, but printed using extrusion widths the exact size of the nozzle. I want more infill cells, not thicker. So I'm doing thick perimeters with thin infill.

[...] If the design isn't proprietary you could also post it and we can have an informal 'how optimised can we get this' competition 🙂 Sometimes stuff like that can be fun and are also good learning opportunities as you try stuff you wouldn't normally.

Yes! I had fun with the other thread before it went off the rails. Printing challenges are a great way to get familiar with ALL the settings. I learned a lot with that all-perimeter print as well as the 210mm cube!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Does MVS have a firmware component?

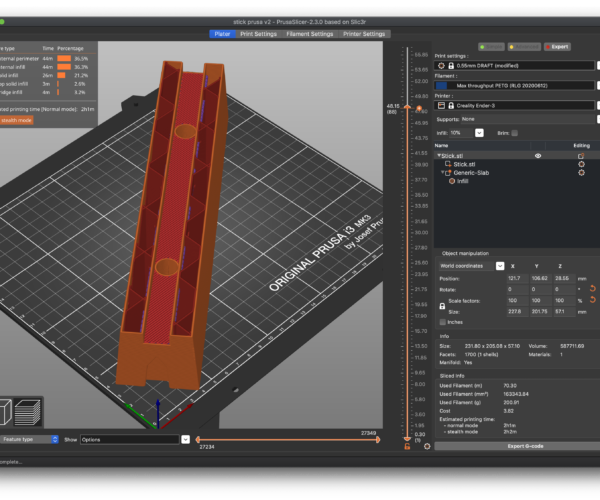

Okay, here's a 3mf file with the model. I came up with it for my training of detection dogs. You put three or four of these components together, drop some target odor into one of the holes, and you have a stick that can be used to train detection dogs to ignore the scent that is flowing down the channel and instead indicate "source", i.e., the hole that contains the target odor.

I (or the dogs) don't really care about the aesthetics much, as long as there are no blatant defects.

With standard settings it takes me about 4 hours with a 0.8mm nozzle and 0.55mm layer height, 15% adaptive cubic infill.

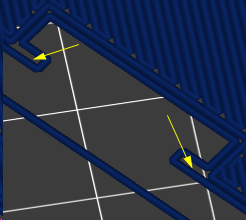

In this 3mf I've set most of the speeds to 0, to make them driven by MVS. Works mostly fine but with the cubic infill I had a few spots on the surface of the groove that had a hole because the top layers didn't get enough support. So I switched to 10% gyroid. Better, not quite perfect, so I'm currently printing one with a modifier mesh with increased infill toward the top (as in the 3mf), as suggested by neophyl. One thing I've noticed are a couple of gaps that I didn't see with stock settings. With stock settings they are filled in.

I can have them filled in by switching gap fill speed back to the default 30 mm/sec but that suddenly adds another hour to the print. I've played a tiny bit with extrusion width but didn't get nowhere.

I'm printing a whole bunch for fellow dog trainers, so cutting an hour (or more) out would be very nice.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Does MVS have a firmware component?

That model is pretty optimized already with it being at mvs for everything but the first layer.

One thing you could do to fill in that gap in the ends is change the first layer extrusion width to 0.8 to match your nozzle. That adds about 20 minutes on as it makes all the first layer print with thinner extrusions. Better than adding gapfill though. That allws those areas to print with no gap.

I wish the modifiers had first layer extrusion width as an option as then you would just be able to do that area but unfortunately its not in the list.

RE: Does MVS have a firmware component?

I had some fun trying to optimize your dog stick. I'm not sure these settings will work well in practice -- do the dogs chew these? -- but it might give you some ideas. I loaded the original 3MF and tweaked a few settings. I've only done slicer time estimates, and haven't verified an actual print.

I tried:

- Selecting grid infill at 10%

- Using a 0.64mm max layer height corresponding to the 0.8mm nozzle set to min. 0.2mm and max. 0.6 layer height.

- Applying automatic variable layer heights at 50% quality. Most print at 0.64mm.

- 1 perimeter with a default 1.5mm extrusion width.

- Using an optimized PETG profile that I used for PPE printing with MVS set to 28mm^3/s.

I'm using very similar settings for large tabletop scenery pieces printed with a 0.6mm nozzle and they're coming out quite usable. Estimated print time has dropped to 2h13m. With MVS of 24mm^3/s, it bumps back to 2h33m.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Does MVS have a firmware component?

@bobstro

Thanks a bunch! I'm in the middle of a production run but will give those parameters a try soon.

One thing I noticed when I switched from my original settings to the ones I used to drive speed by MVS is that the outer surfaces suddenly looked a lot duller (and actually nicer). Not sure how any of this affects light reflection but my point is, I probably want to finish my current run before I switch in case the changes affect appearance.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Does MVS have a firmware component?

@bobstro

Can you upload the 3mf with your settings? When I apply these parameters, I get down to 2h 33m at best (well, a half hour savings is good!) but I don't really see any impact of changing MVS. Throughout the model the volumetric flow rate tops out at 21 regardless of what I set in the Max volumetric speed fields in the print and the filament settings. And going to adaptive variable layer height kills it by adding more than an hour 🙁 I must be missing something somewhere.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Does MVS have a firmware component?

Try this. I haven't tested this, but the results look promising.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Does MVS have a firmware component?

@bobstro

Thanks!

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Does MVS have a firmware component?

@bobstro

Well... Not surprisingly, despite my saying I was going to wait, last night I thought "damn the torpedoes" and ran a print job with your settings.

Alas, I ended up with some big gaps in all horizontal top layers:

Then I switched back to gyroid infill and added a second modified mesh just below the top surface to increase infill. Also slowed top layer speed down. Only added a few minutes. Ran it overnight. This morning I found one of the most impressive layer shifts I've ever seen. Looks like something caught right at the top layer of the groove and ripped everything to the side. That aside, the top surfaces looked a tad better but still some unacceptable gaps.

I'm sure this can be further optimized but at this point I'll just go back to my 3h version to finish the outstanding production runs.

Thank you guys, for all your input. I've learned a lot from this. And I'm sure I'll come back to this again once I've got these things out to the people waiting for them.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Does MVS have a firmware component?

[...] Alas, I ended up with some big gaps in all horizontal top layers:

I specified a 1.2mm minimum top shell thickness, but you can try a bit higher. It does look like you're getting overall under extrusion. Bumping the MVS down a bit may help. I personally have not had much luck with autospeed and always specify speeds for each feature. With external and top perimeters set to 40mm/s and the rest to 70mm/s, it shows 2h1m estimated print time.

Also curious: How do the sides look? Is the single extrusion wall strong enough for your purposes?

Then I switched back to gyroid infill and added a second modified mesh just below the top surface to increase infill. Also slowed top layer speed down. Only added a few minutes. Ran it overnight. This morning I found one of the most impressive layer shifts I've ever seen. Looks like something caught right at the top layer of the groove and ripped everything to the side. That aside, the top surfaces looked a tad better but still some unacceptable gaps.

I'm sure this can be further optimized but at this point I'll just go back to my 3h version to finish the outstanding production runs.

Thank you guys, for all your input. I've learned a lot from this. And I'm sure I'll come back to this again once I've got these things out to the people waiting for them.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Does MVS have a firmware component?

@bobstro

I agree, lowering MVS was going to be my next step.

Re sides: borderline acceptable. Very inconsistent. No holes or anything, and good inter-layer adherence but layers look a bit rollercoaster from the side. Again, I think it's a bit of underextrusion that's driving it. The single perimeter is okay from a stability perspective but the infill shines through big time.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/