Belt Tension: Most Reliable Test?

Hello,

After reassembling my printer, I'm hoping to dial in the belt tension.

However, I'm not sure which of these 3 test methods is yielding the most accurate results and, therefore, should be the one that I use to fine tune my tension.

Part of my confusion stems from multiple articles on belt tension recommendations and how the belt tension meter (#2 below) relates to these:

- Adjusting belt tension MK3/S recommends between 260 and 290 (275~)

- This article references a Prusa community post (dead link) that recommends 255 and 270

- The Prusa MK3 manual recommends 240 +/ 40 (200 - 280)

Also, I cannot recall how much of a difference there should be between the X-Axis and the Y-Axis. Ideally, I'd get them as close as possible, but the Y-axis is easier to adjust for me by accessing the screw on the front of the frame. Currently, the tension screw on the X-Axis is tightened as far in as it will go.

I suspect that I can push the X-axis belt in more, but I don't want to take apart the carriage or start messing with the Y-Axis without figuring out if it is okay as it is based on one or more of the tests below:

- Belt Status (X-Axis = 268, Y-Axis = 207)

After running the calibration wizard, the output on the screen displays the following:

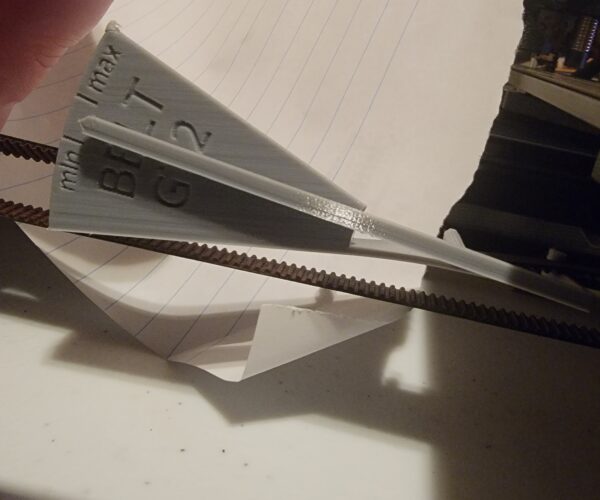

- Tension Meter for the GT2 belts of i3 MK3S+ or Prusa MINI+ (X-Axis = correct, Y-Axis = correct)

Using the MK3s gcode for a tension meter from Prusament, I get the following results:

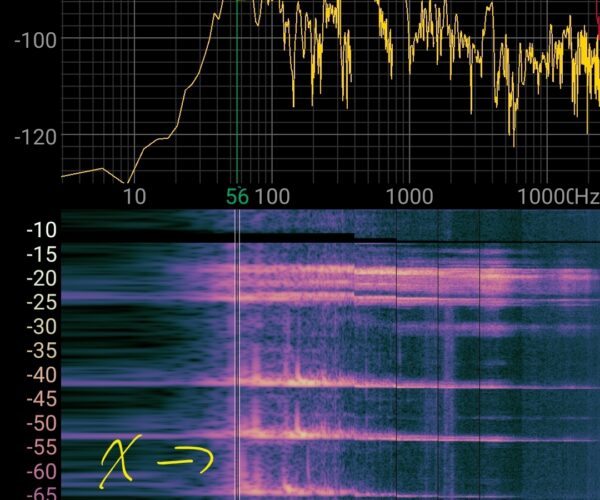

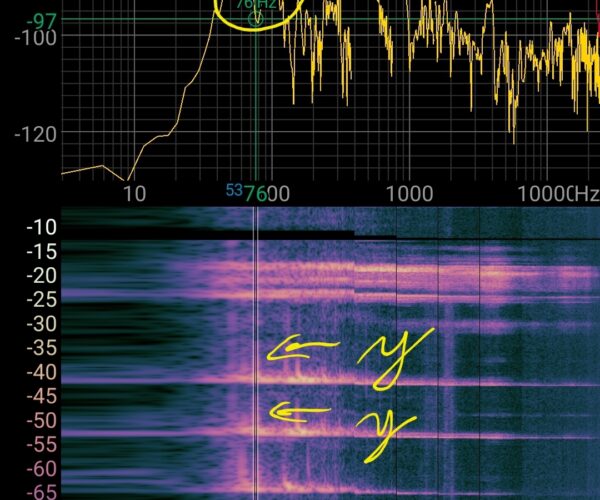

- Frequency Measurements using Spectroid (X-Axis ~= 56hz,-87dB, Y-Axis ~= 76hz, -97dB )

Following the advice from this forum post, I used Spectroid to record the frequency of me plucking the belts.

Admittedly, this is over my head and I need to take more time to understand the output. However, if someone has had success with this method and can help me interpret the output as well as what the "correct" frequencies are, or how they relate to #1 and #2 listed above, I would appreciate it.

I did two plucks per axis:

Best Answer by Diem:

That your numbers are so far out when the meter says you're OK suggests a different issue. Those numbers record the power required to move the axes, they do, in a properly set up machine, equate roughly to the belt tension but they are easily fooled.

Check your smooth rods are clean and lubricated. Check your idler bearings are correctly aligned and running smoothly. With the power off move the axes by hand and make sure they travel smoothly the whole way.

Cheerio,

RE: Belt Tension: Most Reliable Test?

For what it's worth, I gave up looking at any of these numbers a long time ago. I just use the tension meter and it seems to be doing a fine job.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Belt Tension: Most Reliable Test?

I just use my finger to feel the deflection and see if it is too loose.

Correlates well with the numbers. Only had to tighten the y axis once in two years and a bit.

REPAIR, RENEW, REUSE, RECYCLE, REBUILD, REDUCE, RECOVER, REPURPOSE, RESTORE

RE: Belt Tension: Most Reliable Test?

I don't think I'd be as concerned about using the tension meter if the machine values weren't so far apart (207 vs 268); the results seemed more drastic than I've seen before.

Any advice on using it accurately? I try to put it toward the center of the belt but I'm not always sure I'm testing the right spot.

Also, is it better to aim for the belt to be toward the min, mid, or max line on the tension meter? It seems like I'd want it somewhere near the middle?

That your numbers are so far out when the meter says you're OK suggests a different issue. Those numbers record the power required to move the axes, they do, in a properly set up machine, equate roughly to the belt tension but they are easily fooled.

Check your smooth rods are clean and lubricated. Check your idler bearings are correctly aligned and running smoothly. With the power off move the axes by hand and make sure they travel smoothly the whole way.

Cheerio,

RE: Belt Tension: Most Reliable Test?

I use feel as well. I do admit that I will sometimes pluck them to see if I can hear a bass note. 😉

I did print one of those tension gauges some time ago (as most of us have) but I don't even know where it is now.

IIRC that spectrum analysis came very close to an open D string on an electric bass.

RE: Belt Tension: Most Reliable Test?

That your numbers are so far out when the meter says you're OK suggests a different issue. Those numbers record the power required to move the axes, they do, in a properly set up machine, equate roughly to the belt tension but they are easily fooled.

Check your smooth rods are clean and lubricated. Check your idler bearings are correctly aligned and running smoothly. With the power off move the axes by hand and make sure they travel smoothly the whole way.

Cheerio,

That's a really interesting observation. I recently upgraded the printer to the MK3S+, but I did apply lubricant to both axes following the instructions here: Maintenance tips

Due to a part of the X-Axis carriage that snapped and ended up scraping my smooth rods, I ended up replacing the bearing. When I tried to use the Prusa lubricant applicator set (5g) on my X-Axis bearings, however, I think I ended up forcing some of the small ball bearings out and had to replace the bearing again.

I had better luck with the third set of bearings, but I didn't touch the ones on the Y-Axis.

Any advice on how to make sure I'm lubricating the bearings correctly, if the Maintenance Tips are insufficient, and/or applying the lubrication to the inside of the bearings correctly as well?

Regarding the idler, I actually loosened the front screws on the printer attempting to make a slight adjustment to the tension per these instructions: Adjusting belt tension MK3/S - Y-axis belt Was that a mistake and they should be tightened/flush to the frame instead?

Regular maintenance is best. When printing more than 12 hours per day I clean and lubricate monthly. In lighter printing periods it can drift a bit.

part of the X-Axis carriage that snapped

?? are your belts too tight?

When I tried to use the Prusa lubricant applicator

I built mine before the applicator existed and none of my bearings have grease inside; they are just as the manufacturers supplied. I did replace two as a matter of course when I replaced an X axis idler carriage that had worn badly when the pulley collapsed and twisted but they too were fitted as supplied with no extra grease.

My assumption is that it's better to do a little maintenance frequently than a lot occasionally.

If the Y idler is flush to the frame the belt is too long. There should be a small gap or you cannot fine-tune the tension.

Cheerio,

RE: Belt Tension: Most Reliable Test?

My assumption is that it's better to do a little maintenance frequently than a lot occasionally.

I'm from the same school. A tad of lubrication of the rods, tightening of screws, and a few sprays of compressed air every four weeks or so.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Belt Tension: Most Reliable Test?

That your numbers are so far out when the meter says you're OK suggests a different issue. Those numbers record the power required to move the axes, they do, in a properly set up machine, equate roughly to the belt tension but they are easily fooled.

Check your smooth rods are clean and lubricated. Check your idler bearings are correctly aligned and running smoothly. With the power off move the axes by hand and make sure they travel smoothly the whole way.

Cheerio,

You were absolutely correct with your assessment. Somehow, most likely as a result of making the mistake of working on the printer when I was too tired, I had overtightened the front Y-Belt idler.

I thought I was moving it freely with my finger, but once I loosened it up and applied lubricant to the smooth rods as suggested, I could use the tensioner reliably and my values on the screen are now both consistently between 250 and 260.

Thank you for helping me understand what I was seeing and gaining more insight into the workings of the printer!

Thanks for reporting. It's always good to get feedback.

Often the OP drops off the thread after advice is posted and whilst it probably means a fix was found we can never be quite sure we were right.

Cheerio,