Bearing Lubricant - Consolidated Info (& a few questions)

I'm new to 3D printing - recieved my i3 MK3S kit and am building it now. I'm at the Y-Axis step and thankfully came across many bearings discussions. I've paused building for now until I wrap my head around this issue. My bearings are labelled 'LMU8' (which apparently are the Misumi upgrade that many people mention?)

I've tried to summarize everything I've read so far, since information is scattered, and repetitive. Hopefully this will help someone else, and I'd find an answer along the way with your assistance. Please let me know if anything needs correcting/adding.

-----

Two lines of thought for bearings:

-

The manual states that the bearings are pre-lubed, no need to touch them, install as is and move on until you need to perform maintenance down the road.

-

The manual is wrong, the liquid covering the bearings is simply anti-corrosion, and it may function as a lubricant for a short period of time, but after that it will wear out and you'll have problems (gouged rods, vibrations, noise). Solution: Degrease the bearings and apply a different lubricant instead. (Upgrading bearings is also an option but that's a whole different discussion, beyond my knowledge level)

Regardless of which route is 'correct', I'm going with option 2, because I haven't built my printer yet, so worse case I am just doing preventative maintenance, and best case, I avoided many headaches later.

From here, it branches out into different opinions on how to go about it. Various points and questions below, not in any particular order.

Degreaser:

-

Use 99% Isopropyl alcohol (IPA) to strip existing chemicals

-

Acetone is a definite NO, as it will damage the bearings.

-

Using a lower concentration IPA means introducing water into the bearings, increasing the risk of rust

-

Question: It's currently hard to obtain 99% Isopropyl alcohol (IPA) for me. What are some alternatives I can safely use instead?

Lubricants:

-

Apply via the 'packing' method. ( https://prusacommunity.com/set-your-bearing-straight/ or search 'Packing a linear bearing with grease' on YouTube) Many people have done this option, especially using a packing tool printed from thingiverse. Some people say this is too much and can jam up the bearings. Question: I haven't built my printer yet, so can't take advantage of the packing tool. Any other effective methods of doing it?

-

Use 'Superlube' 92003 or 21030

-

Alternatively, use lithium grease instead of Superlube.

-

Question: Can we use the small Prusa lubricant tube that came with the kit? What are options for people who don't have access to Superlube/lithium grease?

Other:

-

Some insist on taking the machine apart and greasing the inside of the bearings.

-

Others simply grease the rod and run the bearing back and forth, however responses to this method mention that the bearings have a guard on them which keeps the inside grease inside, and outside stuff outside; so greasing via the rods wouldn't work. If you still want to grease the rods, do not grease the threaded one, only the smooth ones.

------

Selfishly summarizing my questions here, if you read this far thank you.

-

If my bearings are in fact upgraded Misumi ones, should I assume the factory liquid is still only anti-corrosion and should still re-grease them?

-

What are alternative degreasers other than 99% IPA?

-

Can I use the Prusa lubricant instead of Superlube or lithium grease?

-

What are alternative lubricants besides Superlube/lithium grease?

-

How can I 'pack the lubricant effectively without the printed tool?

Moderator Edit.

Mrizvi1 stated the following in his final post, belowI ended up using 21030, and pressing in with two rods to fully lubricate the bearings.

RE: Bearing Lubricant - Consolidated Info (& a few questions)

Welcome to Rabit hole Hell.

Many folk will have many answers,

Here are mine!

there is NO absolute Best answer.

I Lubed all of My five Prusa's during building,

Different lubricants were used each time,

My latest Prusa is sat beside me printing happily, with Prusa White Lithium Grease.

Prusa Grease may not be the Absolute best lubricant in the world, but it is certainly good enough for the job in hand.

There are at least two SuperLube greases, one of which is too thick for Linear Bearings.

So you could actually do a disservice to the printer using the wrong one.

I have never used a Lube Injection nozzle.

Nor have I ever washed my bearings out, with IPA.

I am currently not burning in hell. even though some of our contributors will wish it upon me.

My technique is to mark the run of the bearings, on the outside of the shell, with sharpie indellible pen,

~then I squeeze lube into the bearing from one end, then put my finger over the other end, and insert a smooth rod into the bearing, this causes the grease to be distributed into the bearing tracks. I repeat with the remaining brearings.

If the bearing is mis aligned, it should be taken if the smooth rod, and re inserted carefully in the correct orientation, Linear bearings are not intended to rotate, only to run along the smooth rods.

after assembly there may be a surplus of Lube at the ends of the Smooth Rods, Wipe this off with Disposable paper towels.

Don't over tighten the U bolts on the Y axis, and be careful tightening the back of the X axis.

Happy Printing,

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Bearing Lubricant - Consolidated Info (& a few questions)

I purchased my mk3s 6 months ago.

If I had it to do all over, I would degrease and put white lithium into the bearing. As far as packing or not packing, I would have to do more research, but I'm leaning toward not packing, (I did plan on "injecting" a heathy amount under the "cage". Also IMHO, I would think any high temperature grease, would work. But I'm also not a grease expert, and don't know for sure. I looked at several different options at the automotive store. You might ask one of them.

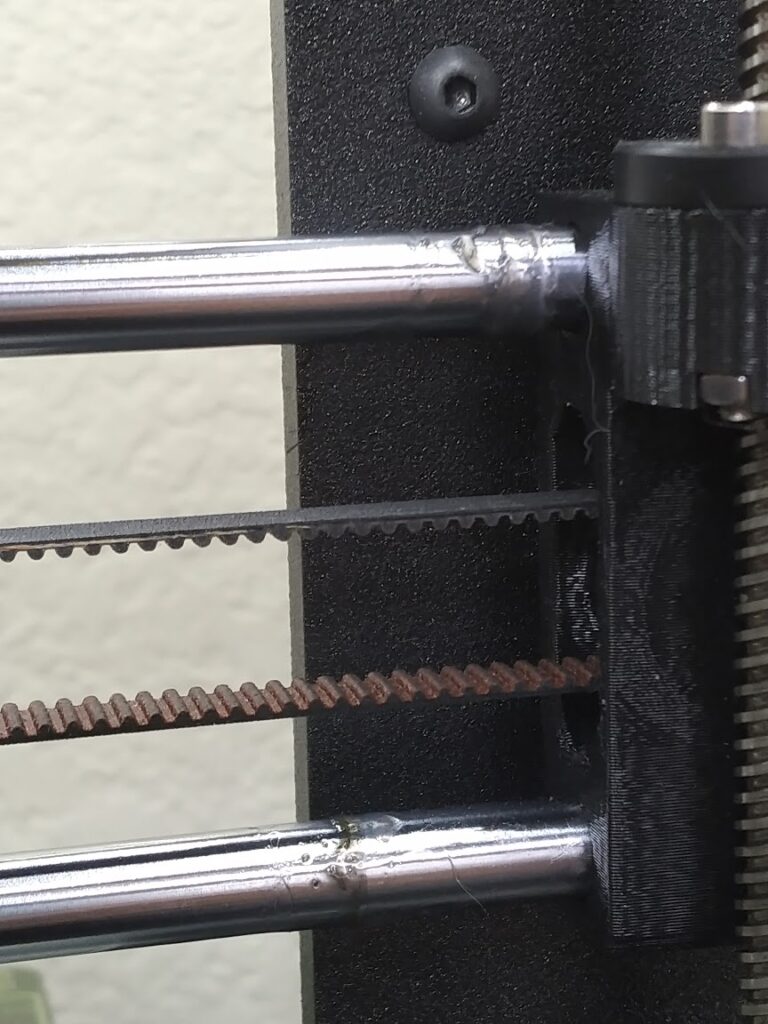

With that said, I purchased (and limped along) with Permatex White Lithium Grease from my major automotive store. By putting grease on the rods using a Q-tip, when I thought it needed it. On my printer (and it could have been something I did wrong) there formed a black sticky residue on the rods. First weeks in on the X, then weeks after the X on the Y, and then about a month after the Y, on the Z. I didn't do any analysis of the black sticky substance, but it would appear to my untrained eye, that the rubber seal was either breaking down, or breaking in, and coating the rods with a VERY thin coat of reside, which cleaned up easily with windex. At a point in time, I did put more grease into the bearings on the X, when I had to break it down, to clean to a level to meet my needs. I can easily promise you the "on the rods method" is a temporary fix, and the rubber seals (if too much is put on) "wipe" the excess off, and deposit it at the max and minimum ends of the rods. So a little in this case is better, BUT it also didn't seem to last long before I needed to rub the lithium Q-tip on the rod again. I also had to be careful that a cotton fiber didn't end up on the rod with the grease. Maybe I was being over cautious. I feel that a make-up foam applicator might be better if you choose to go this route, or something similar.

With all that said, the amount of printing I'm doing, I realized that white lithium might not do the trick for me, or the initial oil is not as good as white lithium. So I was worried that I was going to be re-greasing once a month, and this seemed more maintenance work than I was expecting. So I went a different route, and put in the grease/oil less drylin igus bearings. So far this has been a blessing for me, and I haven't had a issue yet (on month 2). I did have to take much care in making sure the I didn't over tighten anything that could crush and bind the bearings. I later found a Thomas Sanladerer youtube video talking about a igus bearing with aluminum casing that might have been a better option. It's also a bit more money than the ones I used. If these fail, I might try those. Either way, I took great care to make sure belts and lead screws were not involved when I was making sure my movement was smooth and error free. In my opinion, the movement was smoother, and quieter. But I also never tried the LMU8 degreased and re-lubed with any other grease. I popped off the old, and cleaned the rods, and stuck the igus on.

As far as degreasers, I again would think any degreaser would work, as long as it won't eat rubber. From what I can tell the bearing are steel, and the seals are rubber of some sort. So brake cleaner, carb cleaner, gun cleaner, are all possible options, IMHO. But I feel this way because the "oil/grease" on the bearings with my printer, and the replacement LMU8 bearing I got on Amazon (that I never used), before I decided to use the igus bearing, appeared to have the same substance on them, that new guns have. I don't know a single gun owner who doesn't clean this off before firing the weapon for the first time, which is the other reason why if I had to do it all over again......

So in short, love my printer. Haven't seen another one that I think is better, only ones that are cheaper or more expensive. They might be better, they might be worse. Prusa is the printer for me, BUT if I was doing it all over again, I would clean the bearings in IPA, mineral spirits, or carb cleaner as all of these I have around the house right now. I then would put white lithium in the bearing if I want to keep things stock (which I like doing). If you had experience putting a printer together (which I didn't until the Prusa), I would set these aside and put in the igus bearings from the start, knowing what I know now. But I don't like upgrading until I've experienced things, and learned some lessons. I will be the first to admit, I'm still learning things almost daily with the Prusa, and I love it because of this.

RE: Bearing Lubricant - Consolidated Info (& a few questions)

I followed the manual on my build, installed the bearings and went on. I slightly over tightened my Y bearings and later corrected it, but did end up with a scored rod. The X axis scored horribly and you can't really over tighten those bearings the same way you can with the Y. Were those problems related to my following the manual? No idea. But here is what I did when I replaced my bearings and rods during maintenance -- ordered replacements directly from Mitsumi for X and Y.

Degreased the bearings in denatured alcohol -- ethanol/methanol mix with less that 1% methyl isobutyl ketone. Be careful with denatured alcohol as the additives can be damaging to plastics and rubber, depending on type and concentration. No issues encountered with Mitsumi bearing seals, but use at your own risk.

Packed with Superlube (I'll check which one when I get back home -- traveling this weekend). Printed the packing tool before tear down.

The difference in smoothness and sound between packed and unpacked bearings was quite noticeable.

Were I to build another Mk3, I would degrease and pack the bearings during assembly. Needed? Maybe, maybe not, but certainly not going to make things worse and may very well make things better.

RE: Bearing Lubricant - Consolidated Info (& a few questions)

Concerning packing without a printed tool - you can squeeze some grease into one end and then push a rod into each end, forcing the grease into the tracks.

RE: Bearing Lubricant - Consolidated Info (& a few questions)

Thank you to all of the above for your insights, I'll review these in further detail soon.

Would this be an acceptable alternative degreaser? It states its rubber safe:

WD-40® Specialist® Industrial-Strength Degreaser

https://www.wd40.com/products/industrial_strength_degreaser/

RE: Bearing Lubricant - Consolidated Info (& a few questions)

I'm definitely hearing mixed message WRT both initial lube and periodic maintenance. (Not to mention replacing and 'upgrading' the bearings.)

The Company Line seems to be that the bearings are pre-lubricated and don't need anything else on assembly. That's the way I assembled it, and also the way I coached someone else who recently assembled one.

Some are saying, often convincingly, that the pre-lube is no good and that the world will come burning down unless you carefully remove it prior to assembly and re-pack the bearings with Superlube.

TFM shows periodic maintenance by rubbing a bit of Prusa lube on the rods, spreading it around, and giving them a good exercise. Some are saying that this will simply wipe all of the lube to the ends of travel, and it's best to put a few drops of light oil on the rods periodically.

So far, what I've been doing is to occasionally apply either Prusa lube, Superlube, or lightweight synthetic oil on the rods. I've had no scoring of the rods, no nasty noises, and no evidence of 'play' or other signs that the bearings are damaged or wearing out.

On one hand, the Prusa folks can't be stupid. They have 1000-some printers in the 'farm' cranking almost nonstop and if there were failures, surely they would have noticed and updated their assembly and maintenance instructions.

On the other hand, the folks who say to clean and re-pack can't be stupid either, and their arguments can sound convincing.

My intention, as of this minute and second, is to continue what I am doing, and if any of the bearings do fly south, I'll probably order stock replacements but err on the side of caution and be sure that they are properly and adequately lubed on replacement.

RE: Bearing Lubricant - Consolidated Info (& a few questions)

Hi,

I would caution against using heavy greases like white lithium or "bearing" type greases in your linear bearings. And I'm not a fan of grease period in linear bearings.

In industrial use, ballscrews and linear bearings are lubricated with lighter weight oils. Granted, these are mostly 100% loss lube systems which would leave puddles of oil on your desktop. But the idea is to prevent stiction. Which refers to the force it takes to overcome all drag to get something moving. Like every time the machine reverses direction.

Greases will often cause stiction issues with motors far larger and far more powerful than the tiny little steppers on a 3d printer. The artifacts caused by stiction can be seen on 10,000lbs machining centers cutting steels as they are machined and can totally ruin tolerances. Those pretty rails the bearings run on would be junked if the grinder that made them had grease in it's bearings.

What to do? Well, I have used a high tack oil like chainsaw bar oil in linear bearings and I 've run them totally dry also. Stiction can still be an issue with chain bar oil, but to a lesser extent than grease could cause. And if dry is chosen, one must accept the wear. A decent medium weight oil is perhaps best. It takes just a light film to be effective. And if the seals are in good shape, it's not likely to cause issues.

It would be interesting to know how many users have greased their linear bearings that complain of artifacts on their prints vs. those that are still running on the initial light oil from the factory.

RE: Bearing Lubricant - Consolidated Info (& a few questions)

Packed with Superlube (I'll check which one when I get back home -- traveling this weekend). Printed the packing tool before tear down.

Superlube #21030. You do not want the #92030 as it is an order of magnitude more viscous.

I should also note that if you order replacement LM8U bearings for Mitsumi, they specifically call out that they are shipped with rust protection oil only and that you should grease them. The note that there will be little interaction between the rust protection oil and the packing grease, but recommend degreasing and drying before packing. I would not expect a cheaper LM8U "knock off" to be any better in that regard.

After about 300 hours of printing since overhaul, the x-axis shows a bit of grime, but nothing terribly bad. It's certainly better than what the oil looked like with the original rods and bearings.

RE: Bearing Lubricant - Consolidated Info (& a few questions)

I just double-checked. Mine is 21030.

RE: Bearing Lubricant - Consolidated Info (& a few questions)

I also use 21030.

RE: Bearing Lubricant - Consolidated Info (& a few questions)

@mark1

I used this stuff to lubricate rocket motors during assembly.

You want Super Lube 21030 Synthetic Grease (NLGI 2). I am pretty sure it is the same thing I order in the big canisters (Super Lube 41160 Synthetic Grease (NLGI 2)). The smaller tubes in the first link are more useful in 3d printers. I have also have had good success with FYSETC 3D Printer Lubricant.

--------------------

Chuck H

3D Printer Review Blog

RE: Bearing Lubricant - Consolidated Info (& a few questions)

Thank you all for the knowledge. I ended up using 21030, and pressing in with two rods to fully lubricate the bearings.

I would update the original post info with the latest insights, but I don't think my post can be edited anymore.

RE: Bearing Lubricant - Consolidated Info (& a few questions)

New bearings will be sent to me soon. I had always washed out the bearings with IPA beforehand. However, I will probably not do that this time but grease and install them directly. I assume that you have not washed out any of your bearings with IPA to date? Or has something changed?Regards Cloud

Welcome to Rabit hole Hell.

Many folk will have many answers,

Here are mine!

there is NO absolute Best answer.

I Lubed all of My five Prusa's during building,

Different lubricants were used each time,

My latest Prusa is sat beside me printing happily, with Prusa White Lithium Grease.

Prusa Grease may not be the Absolute best lubricant in the world, but it is certainly good enough for the job in hand.

There are at least two SuperLube greases, one of which is too thick for Linear Bearings.

So you could actually do a disservice to the printer using the wrong one.I have never used a Lube Injection nozzle.

Nor have I ever washed my bearings out, with IPA.

I am currently not burning in hell. even though some of our contributors will wish it upon me.

My technique is to mark the run of the bearings, on the outside of the shell, with sharpie indellible pen,

~then I squeeze lube into the bearing from one end, then put my finger over the other end, and insert a smooth rod into the bearing, this causes the grease to be distributed into the bearing tracks. I repeat with the remaining brearings.If the bearing is mis aligned, it should be taken if the smooth rod, and re inserted carefully in the correct orientation, Linear bearings are not intended to rotate, only to run along the smooth rods.

after assembly there may be a surplus of Lube at the ends of the Smooth Rods, Wipe this off with Disposable paper towels.

Don't over tighten the U bolts on the Y axis, and be careful tightening the back of the X axis.

Happy Printing,

regards Joan

RE: Bearing Lubricant - Consolidated Info (& a few questions)

My latest printer is a Mk3.9, it re uses the X and Y rods and bearings, off a previous Mk3 and added 10mm rods and bearings for the Z axis.

to be absolutely honest, I didn't check which Lube, the original Mk3 had previously used.

I Didn't wash the re used bearings out I simply used the Prusa Provided 8mm grease nozzle and a tube of Prusa Lube grease, to re grease them, and the 10mm bearings were greased with the 10mm grease nozzle and the remains of the Prusa lube.

And it's running fine

I Think washing with IPA, might be the ultimate assurance of good lubrication... however... IPA comes in various qualities.

IF IPA successfully removes all lubrication, and the IPA is a lower quality solution. it may well contain a significant amount of water, when the alcohol evaporates, it may well leave the water behind. which could lead to rusting...

I only use 99.9% Lab quality IPA, but I don't think washing out the bearings, makes a massive difference in a 3D printer, which is effectively a low load application...if others disagree, that is their privilege... I have no axe to grind, either way!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK