A desperate guy : can't print anything !

Hello all,

I have a really wierd problem with my MK3, upgraded to MK3s. It's been a workhouse since I bought this printer, but I had a bearing failure on the extruder motor and since then, I can't do anything.

I'll try to make it short and sweet, because I've contacted the technical support twice (thanks to Tommy for his help), spent a lots of hours with him and we've tried almost everything, but I still can't print anything.

What happened after I changed the bearing inside the motor (because I had a spare one in hand, so I decided to only swap bearings) : filament was always jamming and that's still my problem now. So after only few layers, the nozzle was clogging and at first I thought that the filament stayed so long inside the nozzle, it burnt, creating residues, obstructions or whatever. So I completely disassemble the hotend to clean everything thoroughly with a brass brush, a torch and compressed air. Put new thermal paste on the heat break and so on : same thing happened. I disassembled the hot end like 3 or 4 times, every time I had the same result : filament was flowing good at the beginning, but started to clog during print (at this time, that was variable from 5 minutes to 1 hour).

After I talked to Tommy about the problem he suggested changing the whole hotend, because when disassembling we loose some precision (yeah ok, I'm not 100% agreeing with this, but the torque on the nozzle is kind of hard to get correct to I thought, yeah maybe) : changed the whole hotend including the thermistor and the cartridge and the teflon tube : same thing.

Talked to him again, did some tests and suggested it was the extrudor motor. Ok, bought a new motor and everything around, bondtech gear, all plastic parts touching the hot end and new fans. Changed everything : SAME thing, what the hell, but now I can't do more than the 2rst layer, as soon as it switches to the second, it start to clog.

So now I've changed almost 300$ of stuff on the printer, I mean everything around the hotend, and it's still not working. I need to push the filament with my hand to get it trough the nozzle, otherwise it skips or the motor clic (too much pressure on the bondtech). There is absolutely no sweet spot and since the time I have printers, I approximately know the force needed to push the filament through the nozzle, it's not that much.

Every time, I clean the nozzle with a cleaning filament (because I'm afraid to disassemble the new one), it flows good.. for the first layer, but I can see some texture problem (not uniform).

Ok now I'm thinking that my board is not reading the good temperature. Yeah I've tried different temperature, the better result is very hot (like 280°), but I get the same result eventually (I get few extra layers, not much). My only explanation would be that I just can't get the sweet spot of temperature if my board is reading wrong.. but.. I don't see anything not normal with the temperature... Automatic PID is done, it doesn't move more than +/-1° during print, I mean what the hell is going on, I recall the thermistor is new..

Additional info : sometimes I hear my power supply whining, but that's really soft, seems to happen when it's hot and not when starting the printer.

Last things to test : the board and the power supply, after these parts, I would have a new printer no?

Also, please spare me the basics things, I've spent so much time on this printer, Firmware downgrade, printing settings, temperature, filament, reducing the current to the extrudor motor (in case of hot creep), different prints, technical support even sliced me a part.. I'm probably forgetting few mores but yeah, I'm lost.

Thank you guy, sorry I couldn't make it shorter I guess, I appreciate your help in advance !

Best Answer by sebastien.o:

Hey guys,

Finally solved this, it was the heatbreak the culprit, what a mistake they've done by increasing the inner diameter. Changed it for a E3d original and it worked wonderful for 5 prints (approx 50 hours)

Hope it will helps someone !

Thanks !

RE: A desperate guy : can't print anything !

If your fingers can squeeze filaments through the nozzle, then look for problems in the Bondtech drive.

The extruder motor is so strong that it could basically lift the printer if you held the filament.

Is the Bondtech drive wheel properly and correctly mounted on the motor shaft?

One conceivable problem could be that the shaft in idler assembly has loosened so that the Bondtech wheel is not parallel to the drive wheel on the motor.

Check that the idler shaft is really mounted on both ends.

Bear MK3 with Bondtech extruder

RE: A desperate guy : can't print anything !

@rhdreambox

Thank you for your reply, I've tried 3 sets of bondtech (the one when it failed, the one I had previously and a brand new set) and they are properly aligned, with the set screw on the flat spot. The shaft is well mounted on the plastic part and like I said, this plastic part is brand new also.. So the bondtech on the motor is new, well aligned and secured and the idler bondtech is properly seated, gears are meticulously greased to avoid any grease on the filament grip, etc etc.

When I said I can push the filament, the motor must be helping, because just by hand (if I loosen the bondtech for example), I have a really hard time pushing it.

I know the motor is pretty strong, but it doesn't make sens, even if it would worked, I'm pretty sure it would fail really fast.. Don't forget it all started there, so the root cause of filament jam is still not solved, I'll burn the motor if it continues.

Last thing, I actually have more pressure on the bondtech than what Prusa reommand, I think 3 turns more on the screw. If I increase this, I just make the motor clicking, meaning I've reach its limits.

Thank you !

RE: A desperate guy : can't print anything !

OK, I misunderstood you when you said you could feed the filament down by hand.

Then we should look for the problem further down the extruder and then I mean the teflon tube that leads down the filament to the hotend.

The filament should slide very easily through the teflon tube. If for some reason it is deformed at some end, the filament resistance increases and the extruder motor must work harder. If the load is too high, the motor may become uncomfortably hot. An motor temperature of about 45°C for long printouts is normal.

Remove the extruder and inspect the ends of the teflon tube, they must not be deformed. Make sure that a piece of filament can easily pass through the tube. To release the teflon tube, press down the black collet ring that locks the teflon tube and then pull out the tube.

If the teflon tube is deformed in the upper part, you can clean the hole in extruder body up to Bondtech wheels with a drill of suitable dimension (4 mm).

When installing the Teflon tube again, it is very important that it is pressed down into the bottom of the heat sink when simultaneously lifting up the collet ring.

Hope this solves your problem.

Bear MK3 with Bondtech extruder

RE: A desperate guy : can't print anything !

@rhdreambox

Hello friend, sorry for the late reply, I was doing some tests.

So I finally realized the teflon tube was slightly loose (didn't pull the black ring enough), but this doesn't solve my problem. Since I've tried 3 different teflon tubes, all from Prusa and one I cut myself (not chamfered).

So.. I've swap my brand new extruder to my old one and this is the same exact problem : it get stuck down the hot end.

Only way to do ''something'' is to raise the temperature to 280°, but the print is ugly with PETG. I can hear the filament rubbing on something, but I can't find anything. Below the teflon bondtech are well aligned and I've removed the steep ball of the filament sensor to see the other section this is perfectly aligned. Anyways, by hand I can tell it doesn't get stuck before approximately the ''heat break''.

Also, I thought it was my temperature, but at 280 with blue filament I can see it gets a bit burned, seems better at 240 but that's really hard to get something out of it at this temperature.

So, 2 different extruders, the same problem, can it be a cooling problem even if my fan is well oriented and running the right speed ?

Thank you !

RE: A desperate guy : can't print anything !

Anyone ?

I'm receiving a brand new printer next week, I'm trying to figure if I'm swapping the power supply and of the motherboard to test something else ?

Thanks guys !

RE: A desperate guy : can't print anything !

I definitely don't think your problems are electric and there is probably no fault with your extruder motor.

Have you checked that the shaft to idler pulley is stuck on both ends.

If it does not, then the filament will not feed properly and click sounds will occur.

Bear MK3 with Bondtech extruder

RE: A desperate guy : can't print anything !

@rhdreambox

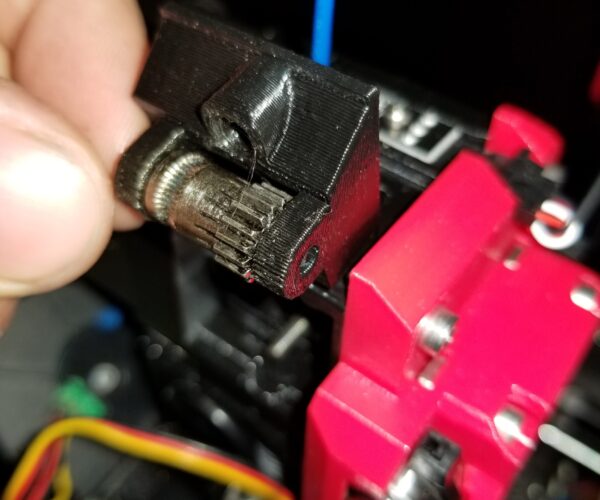

Look at pictures below, idler gear is well mounted and turns freely.

I've tried to take a picture of the aligment, but it's impossible when fully assembled, just cracked it open to show the aligment with the hole in the carrier.. can't be more perfect. It's a bit to the right IMO, but there is no adjustment on the left-right side so...

Other ideas ?

RE: A desperate guy : can't print anything !

That alignment looks too far off to me - mine is dead-on perfect. I would guess that it doesn't feed well or at all just by looking at that.......

Is your printer grinding? Bearings squeaking? Motors smoking?

Step 1) Wash your Steel Sheet

Step 2) Return to Step 1

RE: A desperate guy : can't print anything !

Is it a part you printed that is out of tolerance? Or is it possible that extreme temps warped the PETG?

Is your printer grinding? Bearings squeaking? Motors smoking?

Step 1) Wash your Steel Sheet

Step 2) Return to Step 1

RE: A desperate guy : can't print anything !

@nilok

You're talking left-right alignment (no adjustment) or front-back (bondtech adjustment) ?

About parts, as I said before all plastic parts touching the extruder and the motor were changed for Prusa factory printed parts. I haven't print anything since (not able 🤒 ).

I spend some time yesterday on the printer and I can be sure that aligment above the heat break is perfect. Teflon tube is OK, bondtech are OK, filament sensor. I've removed everything part by part then tried to extrude. The problem is somewhere close to the nozzle by the length of the filament.

Thanks!

RE: A desperate guy : can't print anything !

For those who are interested, after buying a brand new Prusa and having the same problem, I found the culprit.. the heat-break.

I found I'm not the only one having trouble with the 2.2mm heat-break. For now I can easily print PLA and russian-roulette some PETG..

I printed a clip for the black PTFE tube, helped a lot. Reduced the printing temp and removing all retraction.. For now that's the only way to print and original heat-break are now ordered.

Lots of trouble for nothing, not super happy of the technical support honestly, but at least I have some working printers !

Thanks !

RE: A desperate guy : can't print anything !

What is the black PTFE tube? I have only ever seen white. And there should already be a clip for that one.

Otherwise the tube rises up on every retraction.

RE: A desperate guy : can't print anything !

Hello Robert, black clip device (I don't know the exact term for this ddevice) for the white PFTE yes!

And I can assure you I didn't have this clip (the ring that keeps the black devide up) on my brand new MK3S, which I recall, helped a lot. I never had this in fact, this is brand new to me..

Edit : that was confusing..

RE: A desperate guy : can't print anything !

If Prusa is shipping units without the plastic collet we should know about it.

Reference Step 7 and Step 8 here. Yours should have looked like this:

https://manual.prusa3d.com/Guide/How+to+replace+PTFE+tube+on+the+MK3S-MK2.5S-MMU2S/1418

RE: A desperate guy : can't print anything !

Hey guys,

Finally solved this, it was the heatbreak the culprit, what a mistake they've done by increasing the inner diameter. Changed it for a E3d original and it worked wonderful for 5 prints (approx 50 hours)

Hope it will helps someone !

Thanks !