What Z offset for smooth steel sheet?

I got my pre-assembled Mk3S+ a few days ago. At first all was well, according to the stats I've got around 100m of filament through it (almost 3 days of print time) and maybe 20 successful prints. Bottom layer wasn't always perfect, but usually ok. Then I finally got my first print that didn't stick much at all and went spaghetti. I've been cleaning about every 2-3 prints with IPA 91%, so I kinda decided there must be something else wrong.

I decided to just run the calibration wizard in the LCD menu, thinking it would just go through the stuff I'd done on day 1. Mistake... it does a lot more that I didn't do. Presumably stuff they did at the factory during assembly.

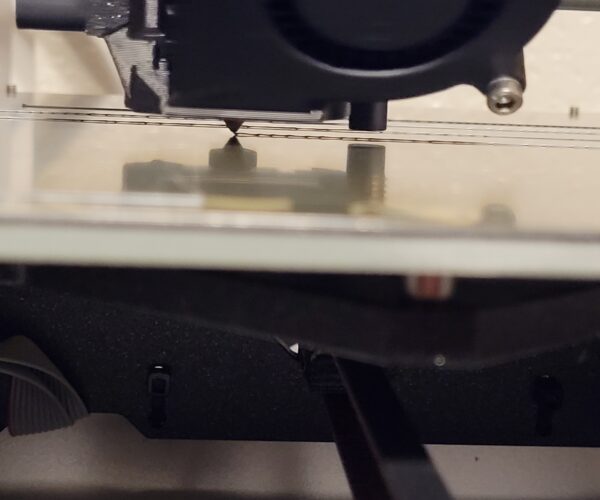

After that finishes, It seems like the nozzle is *way* above the bed, 1-2mm. During the first layer wizard, I have to use a setting around -1.3 to -1.4mm to get it close.

Can anyone check what their offset is for the smooth steel sheet? I want to know if this is "about right", or if the expected value is zero (+/- a little for manufacturing tolerances). I can't find any expected values in the documentation, and I don't know what it was at before I did the wizard. Interestingly, and perhaps very relevantly, the steel sheet itself measures about 1.4mm thick with my calipers.

Thanks!

RE: What Z offset for smooth steel sheet?

The Z setting that works for you will depend on exactly what height the PINDA inductive sensor is mounted at, as well as how that particular sensor responds. That does sound quite high (and you should consider adjusting the sensor downward), but what matters is the shape of the first layer extrusion, not how the Z position is being measured — as long as the results are consistent.

RE: What Z offset for smooth steel sheet?

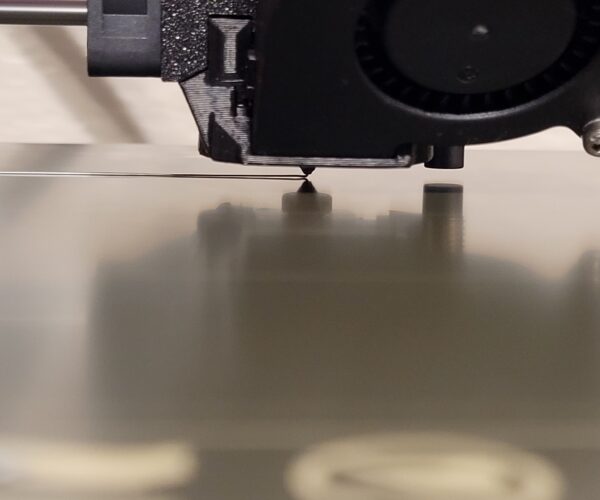

If you want, you can run a first layer calibration and post a picture of your results. The exact number of the z-offset is not as significant as how that first layer calibration looks and folks on the forum can give you guidance by looking at the picture. The z-offset can also change over time as your nozzle gets worn. It is not a matter of finding the perfect number and setting it once and forever.

Mk3S+,SL1S

RE:

Interesting, but I see I needed to be more specific. It would be best if you let entire first layer calibration complete and then take a picture of the entire sheet from above looking down at the sheet. The most important details are the sharpness of the 90 degree turns and how the lines of extrusion come together in the final rectangle. And if the line is not sticking you probably need to lower the nozzle (make the number more negative).

Mk3S+,SL1S

RE: What Z offset for smooth steel sheet?

That is definitely far too high. The nozzle should be close enough that the extruded plastic is squashed flat (0.2 mm thickness), not round and definitely not hopping back off the surface.

When you finish a first layer test, you should be able to peel it off the bed as a fused sheet of plastic, not separate strands.

RE: What Z offset for smooth steel sheet?

While this has nothing to do with your problem, I wanted to mention that I find the Image itself appealing.

The Filament Whisperer

The Z value can go as far as -2mm before you need to reset the PINDA.

Your current setting is still too high, you need more 'squish'.

Please do as @sylviatrilling asks, show us a completed first layer Z calibration print.

You will eventually discover that just cleaning with IPA is not enough, look up threads here about soap and hot water, you will need it soon.

And yes, that is a good picture ... from a photography POV.

Cheerio,

RE: What Z offset for smooth steel sheet?

Thanks for the help everyone. I got frustrated and had to take a break. My last printer (Artillery Hornet) has completely shot my confidence in my ability to operate a 3D printer, so when I started to have trouble with this new MK3S+... well.

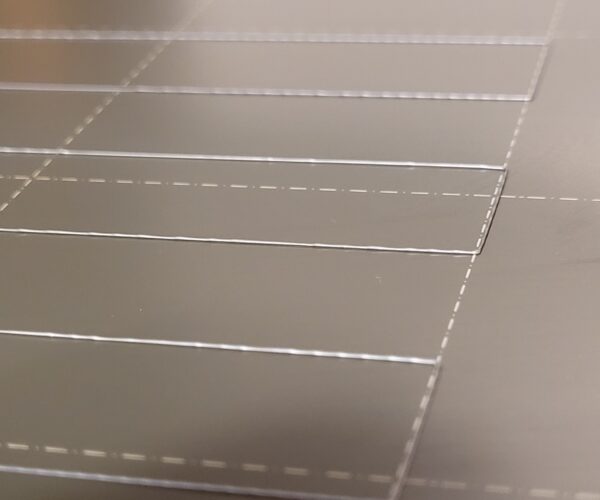

Anyway, I adjusted to -1.4mm... corners seem nice, it's not dragging around, adhesion seems okay. However it's inconsistent.

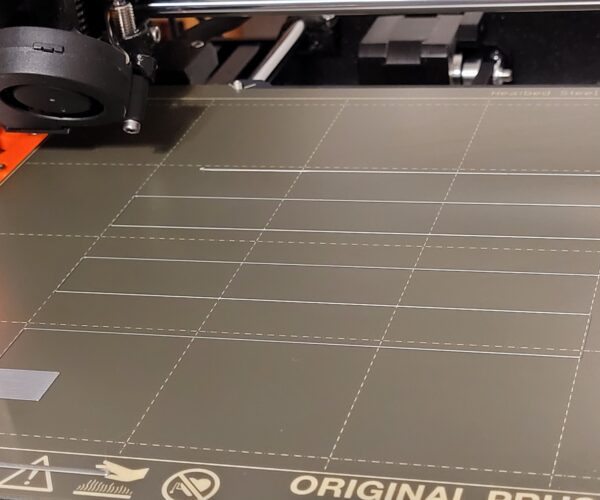

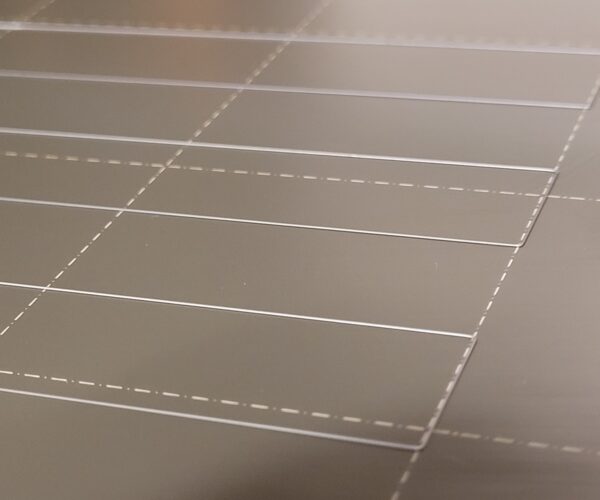

After 2 more attempts I landed at -1.55mm, and got these results:

Seems pretty good to me!

I will definitely look into cleaning with soap and water instead of just IPA... thanks for that bit of advice as well.

You can go lower still.

At the end of the calibration you are aiming to print a single layer *sheet*. It should be possible to peel it off in one and fold it without the threads seperating. If it breaks into lines it is too high, not squished enough. If it is a single sheet but with wavy lines or drag marks on it you are too low.

For most people it pays to use 7x7 mesh bed levelling.

RE: What Z offset for smooth steel sheet?

Lower. Your corners on the 90 degree turns should be a bit sharper.

Mk3S+,SL1S