Trouble cleaning start line from smooth pei

Hi Folks

I've been running Prusa mk3s for some time and as it is already my n+1 printer I'm more than happy.

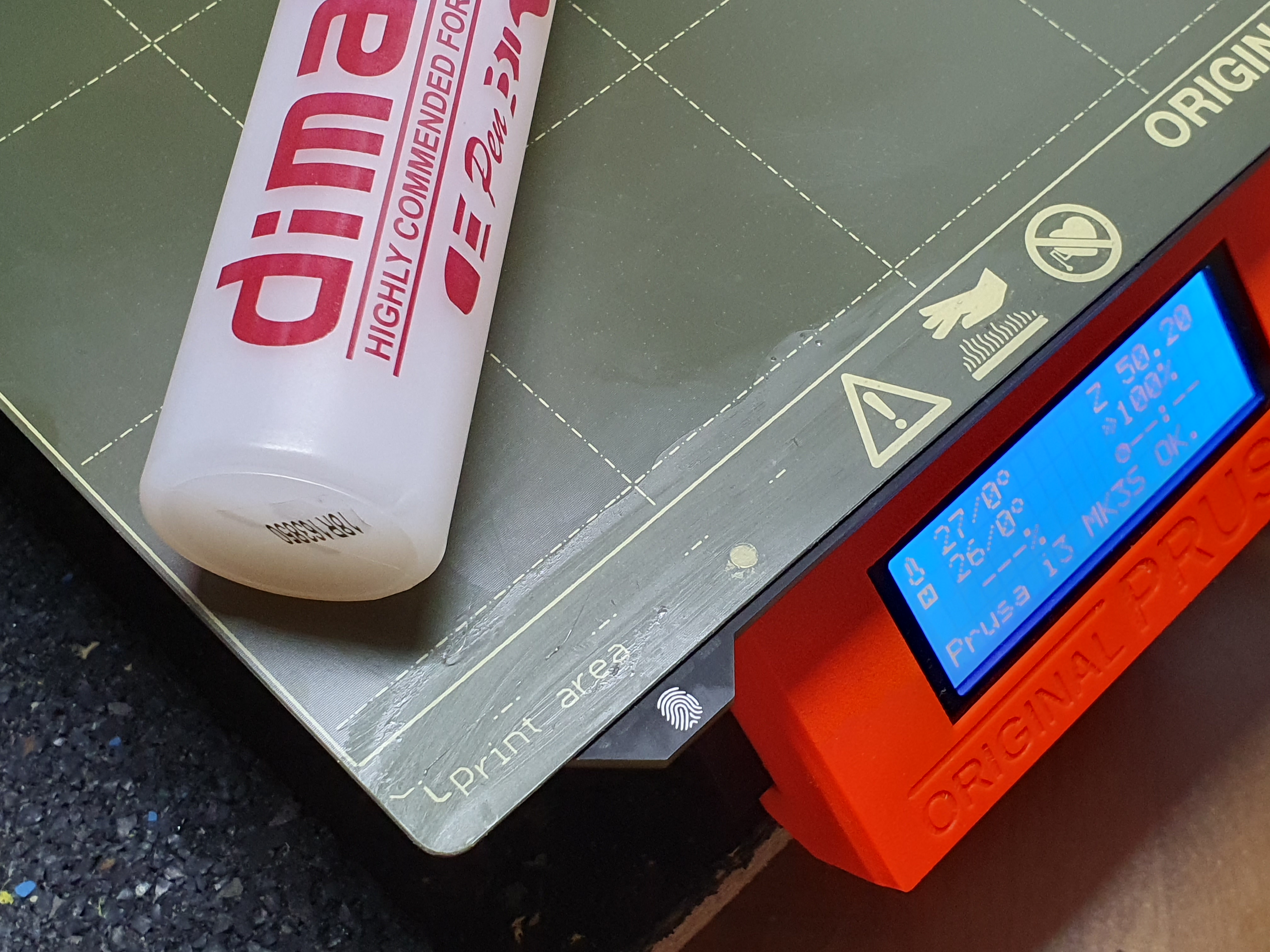

I like smooth pei sheet as I'm kinda used to print on glass with some spray glue adhesion like dimafix.

However I think my smooth pei is now NotSoSmooth in the area of default start gcode initial line.

I have a troubles to clean it of (initial.line) especially after printing with petg. Printed object are removed easily after smooth sheet is colled down but the initial line removal is literally a pain in the ... For me.

My Z is calibrated correctly as it's not my first printer and I have a brief idea how unusual layer should look like.

Are You guys not having the same issues? Are there any tips & tricks for easy removal of the initial line from smooth PEI?

Thabks

RE: Trouble cleaning start line from smooth pei

Can't say I recommend using PETG with the smooth sheet, but what I use to remove the initial line and skirt and any inconveniently flat-therefore-flexible prints (on my powder coated sheet) is a plastic razor scraper — they have replaceable plastic "razor blades" that are sharp enough to slide easily under the filament but soft enough not to damage the PEI. They're sold for purposes like removing stickers without scratching the surface underneath.

RE: Trouble cleaning start line from smooth pei

I use a water diluted windows cleaner to wipe the smooth PEI sheet before each PETG print to protect the PEI from damage and make the part easier to remove. Any cheap windows cleaner can be used even the cheap ECO ones.

I is important to wipe where the initial primer line is printed to avoid the problem you describe.

Have a look at my models on Printables.com 😉

RE: Trouble cleaning start line from smooth pei

Hi thanks for the tips

@area51 what is the purpose? to degrease the surface? I use IPA 99% very often. I actually had the opposite idea to "lubricate" that particular area or spread some thin layer of glue stick?

Area is already a bit degraded due to my trials to remove the filament lines.

RE: Trouble cleaning start line from smooth pei

The point of the window cleaner is not to clean the surface but to actually make the surface LESS effective by creating a barrier.

For PLA you want the surface clean and grease/oil free to get the best adhesion you can. So plain dish soap and lots of HOT water cleaned in the sink. This works much better than IPA as alcohol has a tendency to spread any oils in a thinner layer rather than actually fully removing them. Dish soap breaks down the oils and the hot water removes them. Then once fully clean avoid touching the sheet with your fingers (handle by the edges only).

For PETG though the pei surface sticks TOO well. It can have trouble releasing and there have been several people (myself included) that have torn small pieces out of the pei sheet removing a petg print. Using something like windex puts a barrier between and allows the easier removal of the petg part(s). Of course you can use glue stick too but in this case its not to aid adhesion but to block it still. I find its easier cleaning windex off rather than glue stick.

Remember to thoroughly clean the sheet before going back to PLA.

I'll leave others to recommend for other materials like ASA as I don't have any. What little printing I do with ABS I use a plain steel sheet I picked up from Banggood with the glue stick which has works well enough for printing extruder parts fan nozzles which is about all I use it for.

For the prime strip I use finger oil. Just run your finger along that area every now and again if it bother you.

RE: Trouble cleaning start line from smooth pei

@visual

I use the windows cleaner as a thin barrier to prevent the part sticking too much to the smooth build plate, this is not needed on the textured build plate. I also use it for TPU and TPE (elastic filament) for the same reason.

Some recommend using a glue-stick, but I find it more messy and windows cleaner will do the job. However I use a glue-stick for printing nylon to get it grip better.

To remove grease from build plate, hot water and dish soap will do the job better that IPA. Just quick-dry to avoid rust from forming at the edges.

My MK3's the start strip looks much like yours. Changing the start G-code in PrusaSlicer, the position can be moved to avoid printing at the same spot every time. Someone on the forum suggested a random function to move the start strip around, but I still print at the same spot without problems.

When printing PETG wait with part/strip removal until the temperature is below 40C. I found that some filaments leaves a trace film on the build plate if removed at higher temperatures.

Have a look at my models on Printables.com 😉

RE: Trouble cleaning start line from smooth pei

Thanks Guys for replies,

Now I'm testing another solution spreading a thick layer of 3d print glue called dimafix (NOT AN ADVERT).

It holds really strong when T>85C but in room temperatures adhesion is really low.

So far it seems to work (except not being "eye candy" )

RE: Trouble cleaning start line from smooth pei

@visual

Let us know how your test goes with 3d print glue. It is only a priming strip, no need for "eye candy" here 😉

Have a look at my models on Printables.com 😉

RE: Trouble cleaning start line from smooth pei

I changed my "Start G-code" to print the intro line a bit higher from the bed, the first part of the line @ 0.4mm, and the second part @ 0.6mm.

I also use window cleaner before every print (I always print in PETG).

Here is my intro line g-code for my 0.4 nozzle Prusa.

G1 Y-3.0 Z0.4 F1000.0 ; outside print area

G92 E0.0

G1 X60.0 E9.0 F1000.0 ; intro line

G1 Z0.6 F10000

G1 X100.0 E12.5 F1000.0 ; intro line

G92 E0.0

RE: Trouble cleaning start line from smooth pei

Thanks

@stan-e that's a good approach as well!

After a few today's prints I can confirm that using the 3d printing glue works like a charm!

I guess after a number of prints a new later should be applied to fill the gaps

RE: Trouble cleaning start line from smooth pei

Warming the nozzle to final print temp while positioned close to the bed seems to contribute to damaging the PEI surface. Since I've switched to doing final nozzle warmup at 5mm, and only then moving into final print position for the prime line, I don't have the issue any longer.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Trouble cleaning start line from smooth pei

I've heard that warming legacy version of pinda probe makes it not as accurate as well, maybe it's not a bad idea at all.

@bobstro are you willing to show your start gcode?

Thx

RE: Trouble cleaning start line from smooth pei

@visual

I’ll field that one Bob.

Bobs start code is on his website, check out the links in his signature :). Lots of other useful stuff there too so well worth a read.

RE: Trouble cleaning start line from smooth pei

I had a very similar problem, especially with PETG but I've had PLA stick pretty hard as well. I now have a strip of Kapton tape covering that part of the sheet...the start line sticks well enough to do its job, but comes right off when I'm cleaning up.

Haven't needed it so far on my textured sheet (which I now use for PETG).

RE: Trouble cleaning start line from smooth pei

Good idea to use kepton tape. I'll check it!

So far 3d printing glue is ok except that there's a need to reapply it after stripping-off the initial line.

Stick glue is IMHO worse idea since it holds strong even on cool bed.

RE: Trouble cleaning start line from smooth pei

Blue painter's tape works well. I use glue stick and have no issues with removal, although I also use the gcode routine to raise the nozzle for heating. I only reapply every few months.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…