Re: [Testers Needed] Inconsistent Extrusion

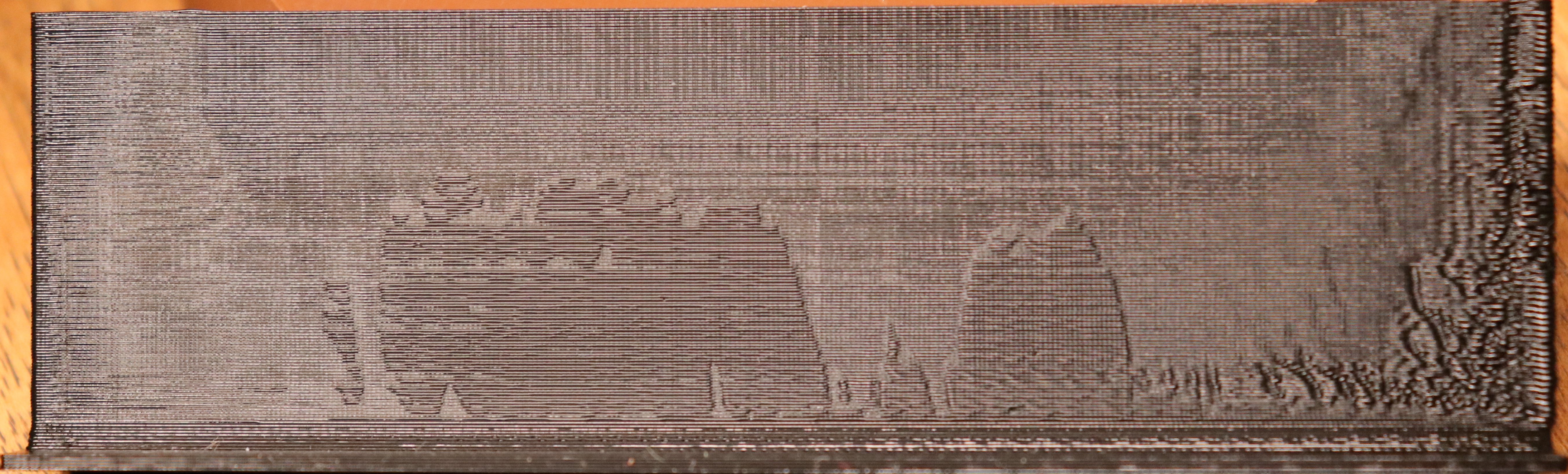

More pictures:

20180416_175729.jpg

20180416_180003.jpg

20180416_175737.jpg

Hi Chris,

Still seeing it. Try a pic with light shining down from above the print, and you'll see what we're talking about. The artifact doesn't show up well in pictures with flash.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed] Inconsistent Extrusion

That was a flashlight from above so it was lit better. I guess I see it a little, but mine seems much better than a lot of others that were posted. Curious, do you guys use the rubber feet? Mine is just sitting on a desk.

Re: [Testers Needed] Inconsistent Extrusion

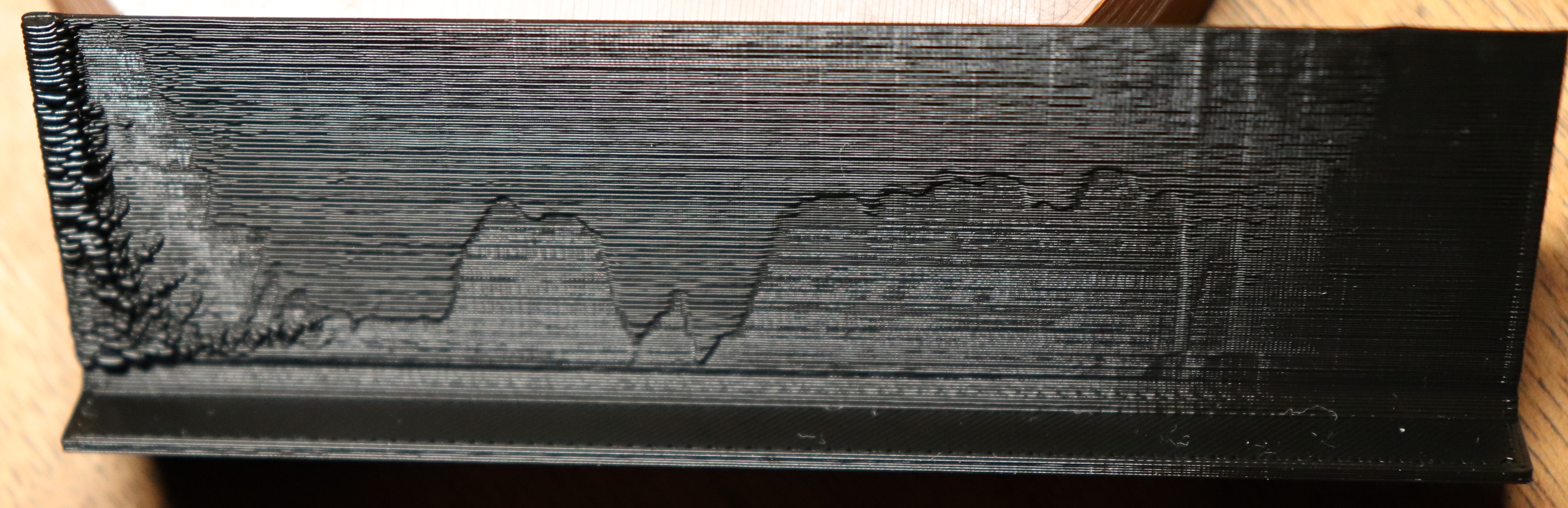

This is the worst I could get it to look no matter the angle of the light and at any other angle it looks flawless (other than the two layer shifts marked). I didn't use a flashlight or flash this time.

20180416_191838.jpg

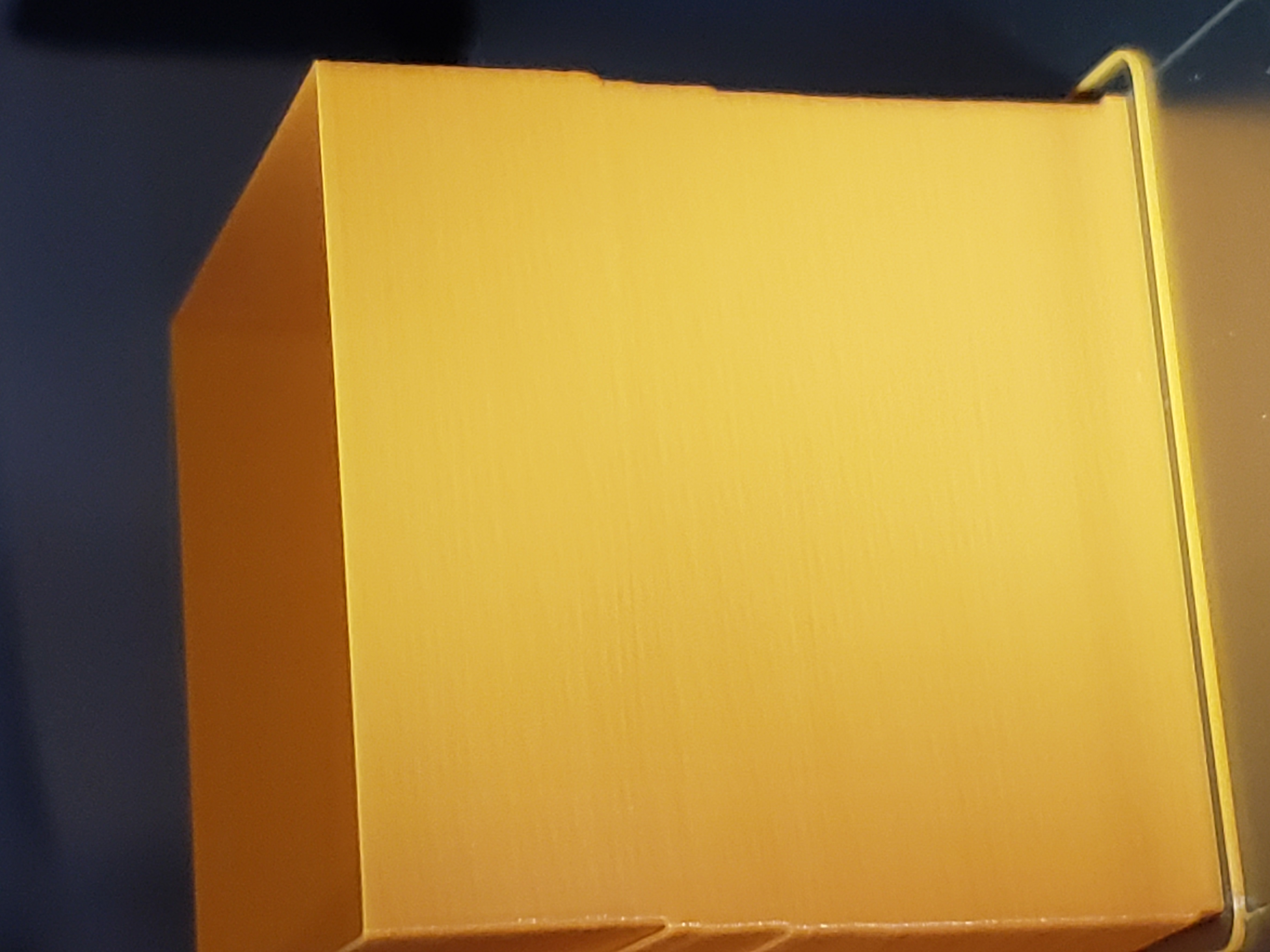

Yep, that's it. Here's what you should be getting:

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed] Inconsistent Extrusion

This is the worst I could get it to look no matter the angle of the light and at any other angle it looks flawless (other than the two layer shifts marked). I didn't use a flashlight or flash this time.

20180416_191838.jpg

Yep, that's it. Here's what you should be getting:

IMG_6790_resize.JPG

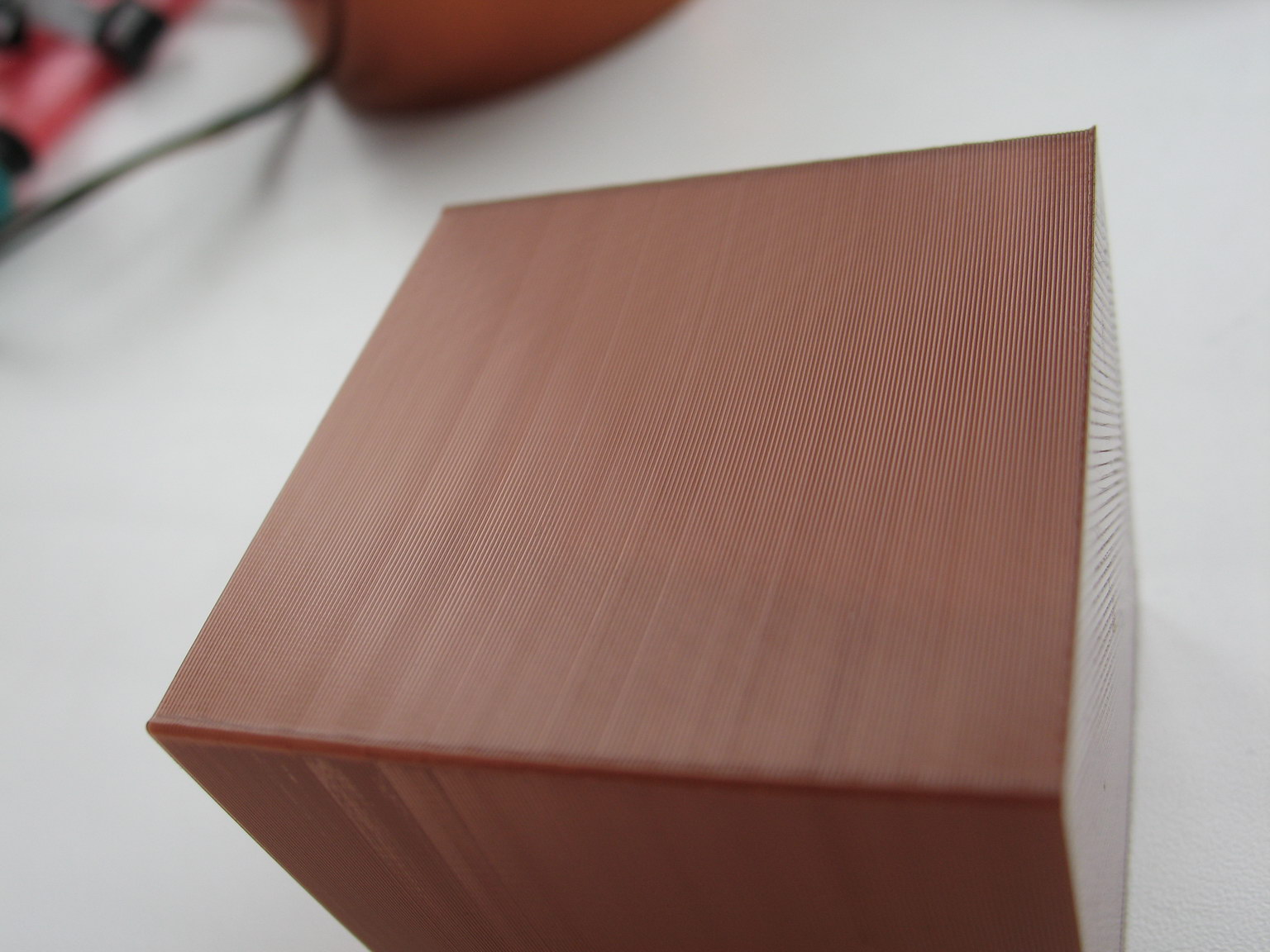

I see the difference, but I actually prefer the way the MK3 prints versus that cube you posted. The reason being is that your cube has the layer lines clearly visible over the entire structure. Mine is blended much better. It is hard to even make out the layer lines on my cube. It may not be perfect, but IMHO the MK3 cube looks better. That brings up a question. What if the print differences between the MK3 and MK2s is intentional so that the MK3 has a more natural (blended look) and the software just isn't there yet?

Re: [Testers Needed] Inconsistent Extrusion

I see the difference, but I actually prefer the way the MK3 prints versus that cube you posted. The reason being is that your cube has the layer lines clearly visible over the entire structure. Mine is blended much better. It is hard to even make out the layer lines on my cube. It may not be perfect, but IMHO the MK3 cube looks better. That brings up a question. What if the print differences between the MK3 and MK2s is intentional so that the MK3 has a more natural (blended look) and the software just isn't there yet?

Prusa has confirmed this is an issue and they are looking into it.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed] Inconsistent Extrusion

I see the difference, but I actually prefer the way the MK3 prints versus that cube you posted. The reason being is that your cube has the layer lines clearly visible over the entire structure. Mine is blended much better. It is hard to even make out the layer lines on my cube. It may not be perfect, but IMHO the MK3 cube looks better. That brings up a question. What if the print differences between the MK3 and MK2s is intentional so that the MK3 has a more natural (blended look) and the software just isn't there yet?

source.gif

Prusa has confirmed this is an issue and they are looking into it.

link? (forums / twitter / facebook / etc)

Just a sanity check.

Re: [Testers Needed] Inconsistent Extrusion

link? (forums / twitter / facebook / etc)

Just a sanity check.

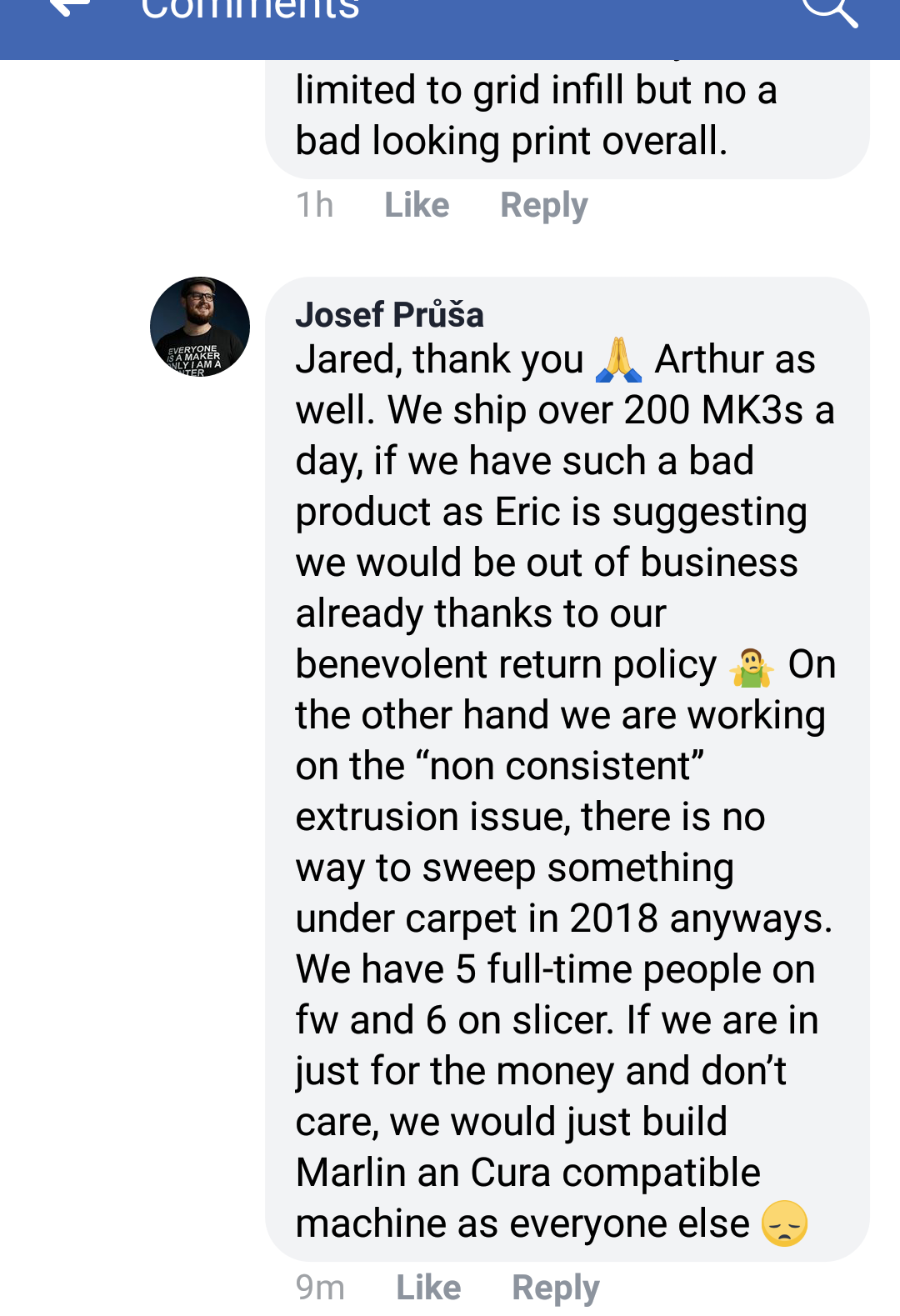

Someone on the Github issue managed to get this out of Josef from a Facebook conversation:

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed] Inconsistent Extrusion

I see the difference, but I actually prefer the way the MK3 prints versus that cube you posted. The reason being is that your cube has the layer lines clearly visible over the entire structure. Mine is blended much better. It is hard to even make out the layer lines on my cube. It may not be perfect, but IMHO the MK3 cube looks better. That brings up a question. What if the print differences between the MK3 and MK2s is intentional so that the MK3 has a more natural (blended look) and the software just isn't there yet?

source.gif

Prusa has confirmed this is an issue and they are looking into it.

I just laughed at my computer and everyone in the office turned and looked at me 😆 😆 😆 😆 😆

Re: [Testers Needed] Inconsistent Extrusion

This is the worst I could get it to look no matter the angle of the light and at any other angle it looks flawless (other than the two layer shifts marked). I didn't use a flashlight or flash this time.

20180416_191838.jpg

Yep, that's it. Here's what you should be getting:

IMG_6790_resize.JPG

I see the difference, but I actually prefer the way the MK3 prints versus that cube you posted. The reason being is that your cube has the layer lines clearly visible over the entire structure. Mine is blended much better. It is hard to even make out the layer lines on my cube. It may not be perfect, but IMHO the MK3 cube looks better. That brings up a question. What if the print differences between the MK3 and MK2s is intentional so that the MK3 has a more natural (blended look) and the software just isn't there yet?

The issue isnt the looks, its the inconsistent extrusion. For example, if you dont have consistent extrusion you cannot print exact dimensional parts(which BTW is what i bought mine for, working parts, not art type prints). For example, printing fine threads on a bolt, or printing parts where fractions of a mm matter such as parts for a CNC rig or 3d printer, is alot harder or impossible if the extrusion is not exact.

Its also impossible to print multiples of the same part and have them actually be the same exact part if extrusion is not exact from print to print.

Re: [Testers Needed] Inconsistent Extrusion

The issue isnt the looks, its the inconsistent extrusion. For example, if you dont have consistent extrusion you cannot print exact dimensional parts(which BTW is what i bought mine for, working parts, not art type prints). For example, printing fine threads on a bolt, or printing parts where fractions of a mm matter such as parts for a CNC rig or 3d printer, is alot harder or impossible if the extrusion is not exact.

Its also impossible to print multiples of the same part and have them actually be the same exact part if extrusion is not exact from print to print.

But isn't this discrepancy measured in single digit microns at most? Is this just theoretical or have you actually tried printing several parts together and the tolerances were off so much that they wouldn't fit together? No way would this affect threads of a bolt.

Re: [Testers Needed] Inconsistent Extrusion

But isn't this discrepancy measured in single digit microns at most? Is this just theoretical or have you actually tried printing several parts together and the tolerances were off so much that they wouldn't fit together? No way would this affect threads of a bolt.

I don't know if any of us would see this enough to affect part fit substantially, but I can say this:

If you don't have a problem with this effect and don't want to contribute to fixing it, why are you even posting in this thread? Are you worried we'll fix things and you will lose the artifact you happen to like? If so, don't punish the rest of us to keep it. You could probably loosen up a belt or two or go use Cura's new fuzzy skin option to similar effect. 🙂

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed] Inconsistent Extrusion

But isn't this discrepancy measured in single digit microns at most? Is this just theoretical or have you actually tried printing several parts together and the tolerances were off so much that they wouldn't fit together? No way would this affect threads of a bolt.

I don't know if any of us would see this enough to affect part fit substantially, but I can say this:

If you don't have a problem with this effect and don't want to contribute to fixing it, why are you even posting in this thread? Are you worried we'll fix things and you will lose the artifact you happen to like? If so, don't punish the rest of us to keep it. You could probably loosen up a belt or two or go use Cura's new fuzzy skin option to similar effect. 🙂

I was going to try to help with it because you and a couple of others were making it out to be a huge deal, even saying that a Monoprice Mini Delta "absolutely destroyed the MK3 in print quality". Which is untrue btw because I have that printer as well. When I saw how extremely insignificant and minor the issue was I was trying to figure out why it was so important to you. Instead you just want to attack anyone that doesn't share your irrational hatred of a minor artifact. Some people just like to complain I guess. I'll stay away from your thread as long as no one comments on my posts. Deal?

Re: [Testers Needed] Inconsistent Extrusion

Is Chris3030 Chris WarDICKI?

Re: [Testers Needed] Inconsistent Extrusion

Hello,

I'm still waiting for my MK3 to arrive. But from what I can see a single wall test got popular. So I decided to create my own single wall test and check the results on my MK2S. I was kind of surprised of the results. I attached pictures and the STL files.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: [Testers Needed] Inconsistent Extrusion

Printed 200um, Hatchbox PLA, 195C.

The stil file attached

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: [Testers Needed] Inconsistent Extrusion

Printed 200um, Hatchbox PLA, 195C.

The stil file attached

That’s a really good way of showing the problem, then prints look terrible 🙁

Re: [Testers Needed] Inconsistent Extrusion

Printed 200um, Hatchbox PLA, 195C.

The stil file attached

That’s a really good way of showing the problem, then prints look terrible 🙁

But that was done on a MK2S and I thought people said the 2S was perfect compared to the MK3? So if the MK2S makes a poor job of this test then there is currently no hope for the MK3 to do it?

Re: [Testers Needed] Inconsistent Extrusion

I did the same test on my MK3 and got a better but not good result.

The problem with the wall is that even if the wall is made 0.45 mm thick, it is printed twice at the same layer level (back and forth). This means that the wall becomes twice as thick as the filament is pressed against the sides, and that is the reason for the bad surface (overextrusion).

It may be a slicer problem rather than a printer problem.

A cube of walls that is one layer thick (0.45 mm) will be correct because the print runs around all the time.

See my examples below. Everything is printed with Slic3r default settings PLA. The wall 0.2 mm and the cubes 0.15 mm.

Bear MK3 with Bondtech extruder