seeking advanced testers

I have reached alpha phase and am looking for a couple experienced testers.

Qualifications:

Adventurous, enthusiastic, fearless, patient, open-minded, clear communicator

Maker: some wiring, part hacking, tools, spare parts supply, etc

Back-up 3D printer(!) w/ PLA and PETG filament

Good knowledge of extruders, gcode, etc

Time to work on this

If you are interested in helping, please PM me here or Thingiverse. I'll hook you up with parts, plans, support. Note that you are replacing your extruder (thus back-up printer needed) and accept risk that this whole thing flops (unlikely) and you'll have to put back the stock extruder (repeat section 5 of Prusa assembly). If that makes you queazy, wait for beta.

Skelestruder Platform V1:

Background:

I wanted to see if I could make a lighter weight extruder to unlock more speed on the MK3. I also wanted to try some new innovations, fix some nagging issues, easier adjustments, etc. while keeping the good bits from PR.

Why a platform? Because it is modular, extensible, flexible. Read on.

Project goals:

Remove: 150-200g of moving mass and center motor on belt-line to increase acceleration/jerk potential

Keep: build volume, e3d v6, Bondtech, laser sensor, other goodness from PR

Improve cooling and nozzle visibility (as always)

[WIP] Enable easy tool-head removal/swap using molex-like electrical connector

Purchase as little new hw as possible

Optimize parts for FDM printing -> RepRap spirit

Alpha progress: I've met most project goals and come up with even more improvements. This replaces both the extruder and x-carriage to minimize moving mass and add innovations.

Main highlights:

* Almost 200g less mass, centered on belt line

* Tool-free rack-and-pinion PINDA mount adjustment w/ scale

* Tool-free quick-lock wishbone suspension idler with tension adjust and manual load/unload

* Shorter stack and free path to better handle flexible filaments

* 4-side cooling with nozzle view

Supports (now or soon):

E3d V6 or E3d volcano

MMU 2.0 (AFAIK)

PINDA or [other bed sensor]

NEMA17 or NEMA14 extruder motor

Direct or indirect laser filament sensor

Std inlet or full PTFE

Other highlights:

- Bondtech gear meshing better aligned with taller more central pivot

- Separate cartridge for easier install of delicate sensor

- Larger viewing/cleaning access to Bondtech

- Simple straight belt clamp with easy access

- snap-lock bearing cups for easy assembly

More surprises in store...

Re: seeking advanced testers

Don't have a spare printer at the moment (or workspace) else I would volunteer. I think this is one of the worst designed components on the machine, and your goals are spot on. Much too heavy, stepper has too much leverage hanging out away from the rods, and bad cooling. Will be keeping an eye on this one.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: seeking advanced testers

I could be up for it, My other printer is laying dormant in its home (The garage).

And I cant make my MK3 any worse than it already is.

Does you ideas include a titan extruder? I have one spare...

Re: seeking advanced testers

PM sent 🙂

Re: seeking advanced testers

I have one taker. A second would be good.

Re: seeking advanced testers

I'm willing to take a look, although I don't know how much time I can commit to testing this.

Re: seeking advanced testers

would this work on a mk2?

my mmu is due an upgrade...

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: seeking advanced testers

would this work on a mk2?

my mmu is due an upgrade...

Joan

yes, if you acquire some Bondtech gears. You can skip the laser sensor. you might need to add a bumper to trigger the x end stop homing switch, but that would be easy. Can't think of other hurdles at the moment.

Re: seeking advanced testers

i have some spare bondtech hobbed gears

joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: seeking advanced testers

Come on, and you didn't just assume me in on this? 😛

Besides getting ready to start printing a 3 week project. (personal, needs done by end of June)

I don't have anything lined up besides continuing to perfect my machine. 🙂

I have 2 other printers. One can print PETG... the other... can't. (it's actually in a box in the closet... but last time I used it, it was fine)

Both of those are "smaller" printers, one delta with a 110 circle build, and the other is, I think, 120x120 square. (the one that can't do PETG)

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: seeking advanced testers

i have some spare bondtech hobbed gears

joan

Really? PM to get details if you want in.

Re: seeking advanced testers

I am really curious about this since my goal right now is to make the existing extruder assembly lighter and more heat resistant. I have rebuilt 2 complete builds with taulman 680 nylon for the extruder body and carbon fiber nylon for the cover. The new proposed extruder that I have printed for the kit I am expecting is Polycarbonite/Carbon Fiber. I have melted 3 extruder bodies and covers and would be curious if switching to a different method would be worth it. I will PM you, but I am not expecting my kit for another 2 weeks :/

Re: seeking advanced testers

I saw the thingverse project before you post this, and i was expecting that maybe is for mk3, i glad you did this because theres some flaws with the original body and we need something more modern 😀 Unfortunately i only have one printer and i need to print so i cant help with testing, but once is stable i would upgrade 🙂

You can also include a mod or spare part for who use cable chains.

Keep up the great work 💡

Re: seeking advanced testers

Hi,

I would be interested in early testing with my MK3. I havn't gotten it yet (week 6 order, so sometime in the next couple of weeks), but I have two other printers which print PETG well. I have some black PETG I can use too - I know the orange I got with the printer doesn't work well with the laser. I do have a significant amount of experience putting together my i3 and modding it, as well as building a mostly custom Smartrapcore.

Let me know how I can help.

Matthew

Re: seeking advanced testers

Here is a pic of the filament free path, which is about half of stock. Hoping this deals with flex better.

66F65446-6BFC-41DF-BEF8-BC3336FB4483.jpeg

Moar pics. Let us critique you violently if we aren't able to help test. 🙂

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: seeking advanced testers

Here is a pic of the filament free path, which is about half of stock. Hoping this deals with flex better.

66F65446-6BFC-41DF-BEF8-BC3336FB4483.jpeg

Moar pics. Let us critique you violently if we aren't able to help test. 🙂

Yes, sir!

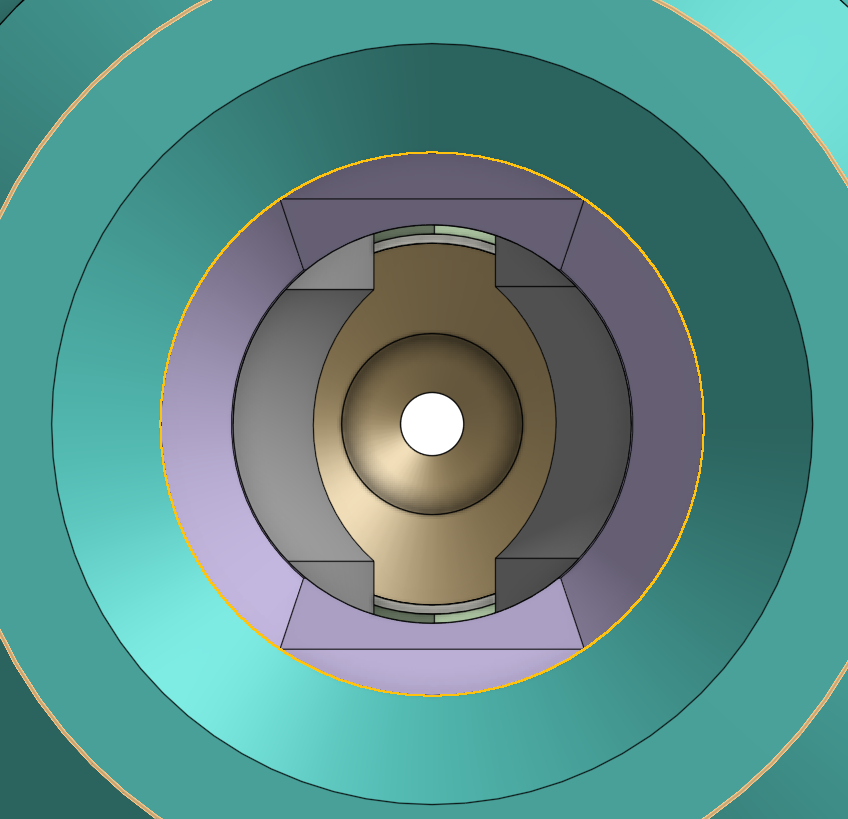

Here is how I am spacing the Bondtech in the neutral position. Is this too tight? Should be good for flex I think.

grey is Bondtech, gold is nozzle, looking straight down through filament path.

Re: seeking advanced testers

damn, I cannot get the e3d out of the stock extruder. I tried to reverse the instructions but it will not come out. It is very loose and tilts out just fine, but catches on either the lip of the block or the collar. I fought it for 15 min and gave up before I break something. Any ideas?

Re: seeking advanced testers

damn, I cannot get the e3d out of the stock extruder. I tried to reverse the instructions but it will not come out. It is very loose and tilts out just fine, but catches on either the lip of the block or the collar. I fought it for 15 min and gave up before I break something. Any ideas?

I had the same thing. It's the tube fighting you, and you're going to have to bend it hard to get it out. Mine was fine, but I wouldn't want to do it repeatedly.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: seeking advanced testers

damn, I cannot get the e3d out of the stock extruder. I tried to reverse the instructions but it will not come out. It is very loose and tilts out just fine, but catches on either the lip of the block or the collar. I fought it for 15 min and gave up before I break something. Any ideas?

I had the same thing. It's the tube fighting you, and you're going to have to bend it hard to get it out. Mine was fine, but I wouldn't want to do it repeatedly.

I've done this before. It takes WAY too much "force". :s

Just make sure you are holding the heatsink. do NOT apply any force past the heat-break. (there's no strength there!)

PS: I'm printing the last parts except for cooling... which will be an ADVENTURE for me... I'm gonna TRY to print them in ABS... If that fails, I'm gonna resort to trying my Atomic Filament PETG+CarbonFiber... (Which was a handout @ MMRF2018) but it's still worth ~30$ for the 1lb roll I got.

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.