Re: [Testers Needed] Inconsistent Extrusion

But if the extruder motor is already at maximum torque and heat output with microstepping, wouldn't the optimal solution be a hybrid gearing and change in firmware to not load the extruder motor at its maximum limits?

The extruder motor is only being run at i think around 500mAh, or around 1/3 of it's capability (motor should have around 1.2 - 1.68 Ah if i remember the specs of the LDO motors Prusa uses. ). Also from an old thread i think the extruder microstepping is still 1/16th, despite the driver.

It IS the hottest motor of the bunch, and will get hot to the point of misstepping on the filament if people print at low temps or high speeds.

Increasing the microstepping only makes it hotter.

I think the solution would be gearing it, and leaving microstepping as it is.

btw, i wanted to upload a reference print of my current full Titan on the MK2:

Will be outfitting my scratch MK3 build next week with these. (can't recommend them enough)

This is PETG (which prints slightly worse than PLA) at 240 degrees, 2 walls, 40mm/s, seam is at the back.

What Titan configuration are you using? Bowden or direct? I have a Titan sitting around and may want to do this mod on my mk3.

Re: [Testers Needed] Inconsistent Extrusion

This one:

https://shop.prusa3d.com/forum/improvements-f14/e3d-titan-on-the-mk2-t3216-s10.html#p28759

(see first post to the mount)

be warned, this is made for the MK2. i had some trouble yesterday fitting the carriage of the MK2 mount to the MK3, so that it finds the calibration points. My hotends will come next week, so i cannot yet get it printing on the MK3.

Re: [Testers Needed] Inconsistent Extrusion

I agree that a geared extruder would probably be a better approach, but that requires some R&D work [actually I think there already is at least one project working on this for the MK3]. Just to close out my thoughts, I did look at the code and it looks like the extruder is been driven at 32 microsteps (double the resolution of the other motors). Also, if I'm reading the code correctly, the extruder has the highest current settings (last of 4 params) but I'm still trying to figure out exactly what this means in terms of motor current.

#define TMC2130_USTEPS_XY 16 // microstep resolution for XY axes

#define TMC2130_USTEPS_Z 16 // microstep resolution for Z axis

#define TMC2130_USTEPS_E 32 // microstep resolution for E axis

//new settings is possible for vsense = 1, running current value > 31 set vsense to zero and shift both currents by 1 bit right (Z axis only)

#define TMC2130_CURRENTS_H {16, 20, 28, 36} // default holding currents for all axes

#define TMC2130_CURRENTS_R {16, 20, 28, 36} // default running currents for all axes

#define TMC2130_UNLOAD_CURRENT_R 12 // lowe current for M600 to protect filament sensor

Re: [Testers Needed] Inconsistent Extrusion

But if the extruder motor is already at maximum torque and heat output with microstepping, wouldn't the optimal solution be a hybrid gearing and change in firmware to not load the extruder motor at its maximum limits?

The extruder motor is only being run at i think around 500mAh, or around 1/3 of it's capability (motor should have around 1.2 - 1.68 Ah if i remember the specs of the LDO motors Prusa uses. ). Also from an old thread i think the extruder microstepping is still 1/16th, despite the driver.

It IS the hottest motor of the bunch, and will get hot to the point of misstepping on the filament if people print at low temps or high speeds.

Increasing the microstepping only makes it hotter.

I think the solution would be gearing it, and leaving microstepping as it is.

btw, i wanted to upload a reference print of my current full Titan on the MK2:

Will be outfitting my scratch MK3 build next week with these. (can't recommend them enough)

This is PETG (which prints slightly worse than PLA) at 240 degrees, 2 walls, 40mm/s, seam is at the back.

UGH, those prints look so, so good. I wonder if there is a way to design a new extruder body similar to the titan using the parts that come with the printer?

Re: [Testers Needed] Inconsistent Extrusion

Thats what I would like to see. If we can design and print a geared extruder upgrade using the existing stepper and existing parts, would be awesome.

Re: [Testers Needed] Inconsistent Extrusion

I agree that a geared extruder would probably be a better approach, but that requires some R&D work [actually I think there already is at least one project working on this for the MK3]. Just to close out my thoughts, I did look at the code and it looks like the extruder is been driven at 32 microsteps (double the resolution of the other motors). Also, if I'm reading the code correctly, the extruder has the highest current settings (last of 4 params) but I'm still trying to figure out exactly what this means in terms of motor current.

#define TMC2130_USTEPS_XY 16 // microstep resolution for XY axes

#define TMC2130_USTEPS_Z 16 // microstep resolution for Z axis

#define TMC2130_USTEPS_E 32 // microstep resolution for E axis

//new settings is possible for vsense = 1, running current value > 31 set vsense to zero and shift both currents by 1 bit right (Z axis only)

#define TMC2130_CURRENTS_H {16, 20, 28, 36} // default holding currents for all axes

#define TMC2130_CURRENTS_R {16, 20, 28, 36} // default running currents for all axes

#define TMC2130_UNLOAD_CURRENT_R 12 // lowe current for M600 to protect filament sensor

See my discussion with metacollin for the TMC2130 current formula. (yes, there's a formula now.)

https://shop.prusa3d.com/forum/original-prusa-i3-mk2-f23/einsy-rambo-on-mk2--t6137-s30.html#p74913

Re: [Testers Needed] Inconsistent Extrusion

I think if I could find a Titan aero mount with the PINDA probe in more or less the same place it definitely be up for trying it.

I have a Titan aero mounted on my other printer with a BL Touch, getting the aero mounted should be easy as the carriage rod spacing is the same. The bedleveling would need the PINDA as the bltouch wound not work with the firmware. Also wiring would be a pain.

I could also use the prusa heater and thermister, filament sensor wouldn’t have a place tho

My titan aero mount for MK2 should be easily adaptable. Same rod spacing and PINDA position.

Re: [Testers Needed] Inconsistent Extrusion

But if the extruder motor is already at maximum torque and heat output with microstepping, wouldn't the optimal solution be a hybrid gearing and change in firmware to not load the extruder motor at its maximum limits?

The extruder motor is only being run at i think around 500mAh, or around 1/3 of it's capability (motor should have around 1.2 - 1.68 Ah if i remember the specs of the LDO motors Prusa uses. ). Also from an old thread i think the extruder microstepping is still 1/16th, despite the driver.

It IS the hottest motor of the bunch, and will get hot to the point of misstepping on the filament if people print at low temps or high speeds.

Increasing the microstepping only makes it hotter.

I think the solution would be gearing it, and leaving microstepping as it is.

btw, i wanted to upload a reference print of my current full Titan on the MK2:

Will be outfitting my scratch MK3 build next week with these. (can't recommend them enough)

This is PETG (which prints slightly worse than PLA) at 240 degrees, 2 walls, 40mm/s, seam is at the back.

What Titan configuration are you using? Bowden or direct? I have a Titan sitting around and may want to do this mod on my mk3.

I'm using it direct setup now so i was gong to use direct again. I prefer direct having tried both.

The titan aero prints ninja flex so well it can print anything!

A god advantage on it too is you can loose a bit of weight with a smaller stepper if needs be but i wont to start with

Re: [Testers Needed] Inconsistent Extrusion

This one:

https://shop.prusa3d.com/forum/improvements-f14/e3d-titan-on-the-mk2-t3216-s10.html#p28759

(see first post to the mount)

be warned, this is made for the MK2. i had some trouble yesterday fitting the carriage of the MK2 mount to the MK3, so that it finds the calibration points. My hotends will come next week, so i cannot yet get it printing on the MK3.

Thanks for the information, I had seen that one. i liked the look of it!

when you get it nearly ready to go id love to chat about it some more

Re: [Testers Needed] Inconsistent Extrusion

I think if I could find a Titan aero mount with the PINDA probe in more or less the same place it definitely be up for trying it.

I have a Titan aero mounted on my other printer with a BL Touch, getting the aero mounted should be easy as the carriage rod spacing is the same. The bedleveling would need the PINDA as the bltouch wound not work with the firmware. Also wiring would be a pain.

I could also use the prusa heater and thermister, filament sensor wouldn’t have a place tho

My titan aero mount for MK2 should be easily adaptable. Same rod spacing and PINDA position.

I think we had a brief chat about this before, i think it would be the quickest way to get a geared extruder on a MK3. your design is pretty good

Re: [Testers Needed] Inconsistent Extrusion

UGH, those prints look so, so good. I wonder if there is a way to design a new extruder body similar to the titan using the parts that come with the printer?

you might wanna give @jltx a call, with his skelestruder. (geared extruder that uses the bondtech gears)

Re: [Testers Needed] Inconsistent Extrusion

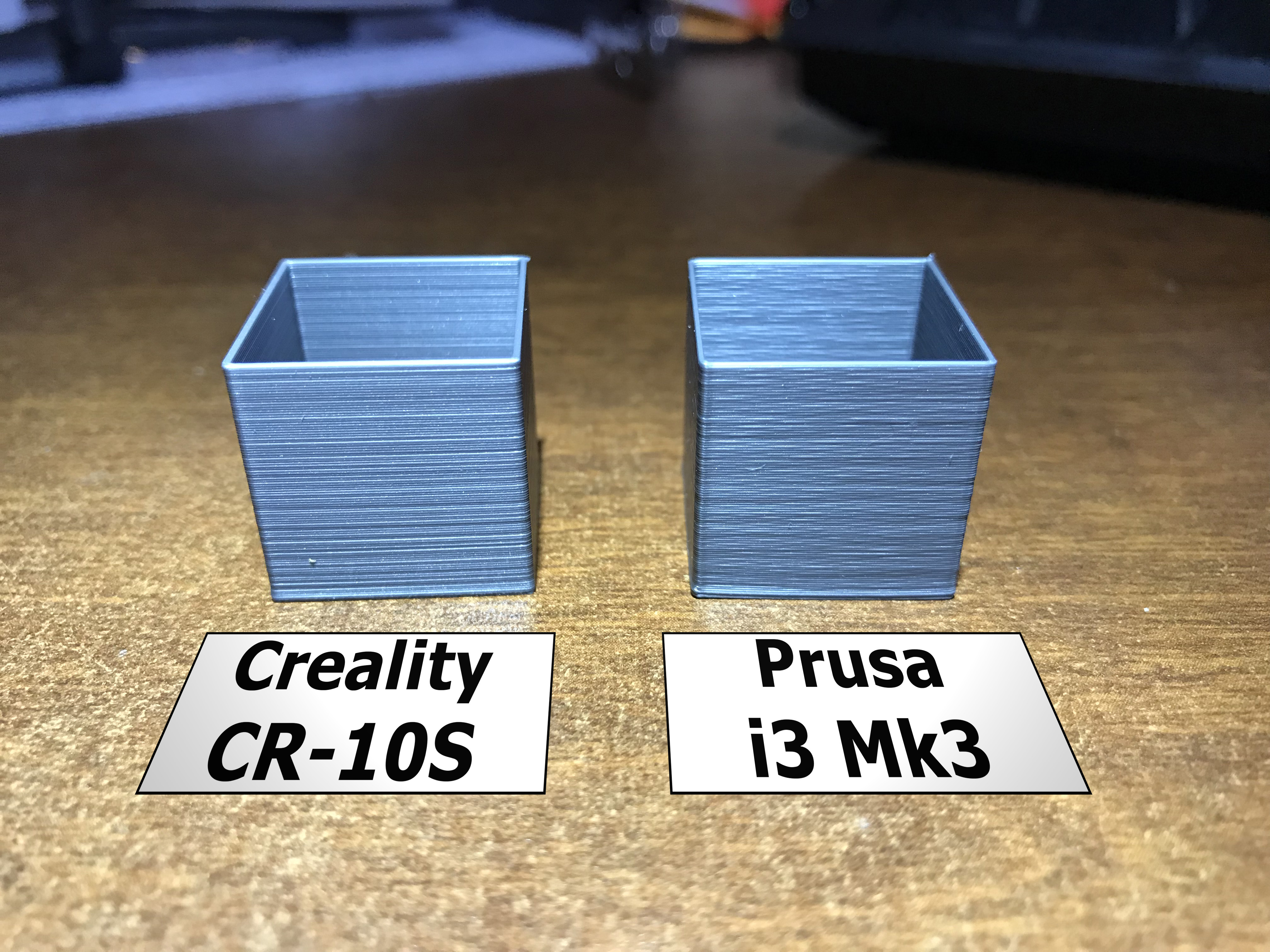

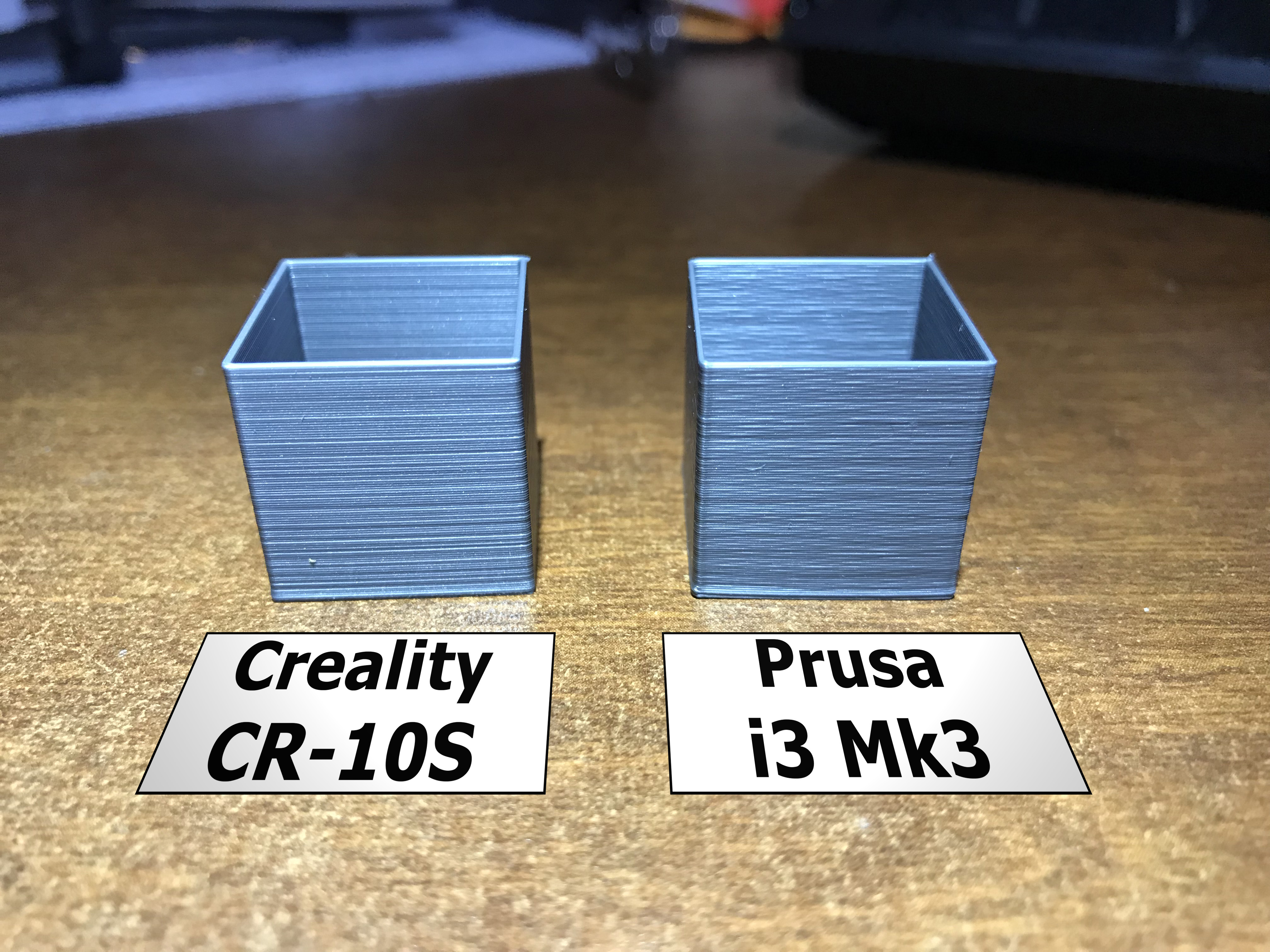

My sample, 20mm cube, 1-layer walls, vase mode, with Prusa PLA. Left is CR-10S, right is Mk3. My inexpert opinion sees positional inconsistency on the CR-10 (but even extrusion), and extrusion insconsency on the Mk3 (but accurate positioning).

Re: [Testers Needed] Inconsistent Extrusion

My sample, 20mm cube, 1-layer walls, vase mode, with Prusa PLA. Left is CR-10S, right is Mk3. My inexpert opinion sees positional inconsistency on the CR-10 (but even extrusion), and extrusion insconsency on the Mk3 (but accurate positioning).

That’s a really good comparison between the two

Re: [Testers Needed] Inconsistent Extrusion

I think I might have a go at this sometime soon, I expect it can’t to be far away form working straight away with not many mods.

Re: [Testers Needed] Inconsistent Extrusion

I think I might have a go at this sometime soon, I expect it can’t to be far away form working straight away with not many mods.

https://www.thingiverse.com/thing:2192480

Note that this one requires FW changes and you lose print volume due to required spacers. I solved all of that.

Re: [Testers Needed] Inconsistent Extrusion

It's possible to synchronize some of the artefacts to the width of the cube by printing a slightly slanted version of the cube:

l=20.68;

f1=1.005;

linear_extrude(height=20,scale=f1) square(l);

echo(l=l,l2=l*f1);

The exact numbers may not apply, just to give an idea.

I get the effect like this:

I'll try with a 2x or 3x scaled version to see if it's vibration of the print head as it will die off in this case.

Re: [Testers Needed] Inconsistent Extrusion

I've seen it suggested in a couple of places that this issue looks like over-extrusion. I'm in the middle of a long print, but that should be pretty easy to prove/disprove when I'm done. However, I don't think it is over-extrusion based on the following items:

1. I calibrated my extrusion rate by running 100mm of filament through the hot end and measuring how much it actually extruded. It extruded exactly 100mm when I tested this.

2. I changed my outer perimeter width to .4 in slicer then measured my spiral vase mode calibration cube and it was exactly .4 mm thick

Based on those two data points, is it still possible this is related to overextrusion? I hope not, because it means it will be impossible to tune/verify the extruder steps/mm based on standard calibration testing if that is the case.

Re: [Testers Needed] Inconsistent Extrusion

In a spanish telegram group we have been looking at the bondtech gears and how they are implemented. I modified the extruder body to fit a whole bondtech bmg extruder and see if that fix the inconsistent extrusion. The problem with this is that I don't own (yet) the mk3, nor a BMG extruder, so I used a model found on GrabCAD not knowing if it is going to fit right.

It is meant to keep everything the way it is now so the body is taller but that's all. The e3d remains in its positition requiring a longer bowden tube to the bondtech extruder. The parts that need to be changed are the extruder body, x carriege, filament sensor cover and idler. So if anyone has the time and some spare filament to, maybe, throw away I don't mind posting the stls here.

Re: [Testers Needed] Inconsistent Extrusion

I've seen it suggested in a couple of places that this issue looks like over-extrusion. I'm in the middle of a long print, but that should be pretty easy to prove/disprove when I'm done. However, I don't think it is over-extrusion based on the following items:

1. I calibrated my extrusion rate by running 100mm of filament through the hot end and measuring how much it actually extruded. It extruded exactly 100mm when I tested this.

2. I changed my outer perimeter width to .4 in slicer then measured my spiral vase mode calibration cube and it was exactly .4 mm thick

Based on those two data points, is it still possible this is related to overextrusion? I hope not, because it means it will be impossible to tune/verify the extruder steps/mm based on standard calibration testing if that is the case.

It can mean your likely still over extruding a bit, I always print this ( https://www.thingiverse.com/thing:24238 ) at 250% scale @95% infill and you should see small gaps on infill and none on top. I set me basic extrusion multiplyer like you have the fine tune adjusting the flow until it’s perfect.

The problem we’re all having isn’t constant over extrusion. It’s seems it’s a mix of over and under hencse in inconsistency of its appearance.

Hope that helps

Re: [Testers Needed] Inconsistent Extrusion

*snip*

It can mean your likely still over extruding a bit, I always print this ( https://www.thingiverse.com/thing:24238 ) at 250% scale @95% infill and you should see small gaps on infill and none on top. I set me basic extrusion multiplyer like you have the fine tune adjusting the flow until it’s perfect.

The problem we’re all having isn’t constant over extrusion. It’s seems it’s a mix of over and under hencse in inconsistency of its appearance.

Hope that helps

Try printing this one.

https://www.thingiverse.com/thing:1622868

The thing is...

100mm of 1.76mm filament has a LOT more "filament" than 100mm of 1.72mm filament.

Also, just because the "extrusion is the proper width". Does not mean it is "perfect" with the way the slicer is slicing the files.

Before I went to MRRF2018, I printed a 10x10x10 cube, with 0.02mm precision. 🙂 I don't use calipers when tuning my extrusion, just the test I linked above.

Print 2 of them, and put them together. If it's "tight" you are over extruding. If it don't "stay" toether, it's too loose. Optimally, you want it so that it slides FREELY along the layer lines, but "binds" sliding "across" the layer lines. This is the point your extrusion multiplier is nearly perfect. When I feel like I am having an issue with extrusion/adhesion/precision, I start printing those. Fixes 90% of my problems.

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.