RE: Recommendations for a 3D printer with build area of 400x400mm or greater?

Yup, so when it's gone it's gone. I was trying to find unsold inventory, but it seems to have dried up.

I have found ultimaker DIY clone kits on aliexpress , but typically at much higher prices. Actually, a full DIY Ultimaker 2 clone project has been posted on thingiverse since 2015, but it's not a kit: you have to procure all the parts and do all the cutting, drilling, and tapping yourself. Maybe it's worth it just to have guaranteed control over the quality.

I'm somewhat puzzled as to why the Ultimaker kinematic mechanics isn't more popular than corexy is. It's plain cartesian, where x, y, and z can be moved simply and independently of one another, and the belts are shorter, and like corexy the stepper's are stationary. What's not to like?

RE: Recommendations for a 3D printer with build area of 400x400mm or greater?

@dimprov

Is it an open source design? I mean, sure it's not hard to reverse engineer but are the actual design specifications out there?

RE: Recommendations for a 3D printer with build area of 400x400mm or greater?

@dimprov

Is it an open source design? I mean, sure it's not hard to reverse engineer but are the actual design specifications out there?

Good question. Surprisingly, the short answer is yes, it's open source. The long answer is that it's closed source while they're developing it, and then they wait a length of time equal to the development time, and after that they make it open source. Confused? This explains it: https://all3dp.com/ultimaker-3-source-files/

RE: Recommendations for a 3D printer with build area of 400x400mm or greater?

@dimprov

That is good news. I did not know it was open source.

--------------------

Chuck H

3D Printer Review Blog

RE: Recommendations for a 3D printer with build area of 400x400mm or greater?

Worthy of note, this guy cost reduced and modernized the classic "original" Ultimaker design and just six months ago put together a nice instructable along with a 17 episode video tutorial on how to make his particular fork (a 300x300x300mm build volume), which seems to have turned out well for him: https://www.instructables.com/Building-a-300mm-Big-Size-Ultimaker-Style-3D-Print/

😎

RE: Recommendations for a 3D printer with build area of 400x400mm or greater?

@dimprov

Pretty neat setup. I like the idea of a warranty. Maybe I will build one after I retire. I will have more time to tinker.

--------------------

Chuck H

3D Printer Review Blog

RE: Recommendations for a 3D printer with build area of 400x400mm or greater?

So Having in hand Mk3, CR10s -moded with linear rails and mk3 extruder in a tent, Sapphire pro with DUET and H2 direct-drive and slightly modified MULDEX IDEX with DUET and tilt bed, month ago A customer came with a prototype of a huge set of parts from ABS 460*300*100 , I have to make about 25 parts. After browsing my options as CR10 s5, Trodon , CR10 max and Tronxy 500 I decided to build my own design CoreXY .

Budget was an issue so here what I came up with for 3weeks from the Idea to working machine

I went for smooth rods for X and Y, because i made this modular, if I need bigger in any axis I will need 4 new members, new rods and new build plate. The rods are dual 20 mm for X and dual 16 mm smooth tubes for Y, this is kind of overkill but when and if I go bigger it will payoff. For the Z I used tr8 leadscrews with anti backlash nuts and 3 20mm linear rails ,that I had from some project.I used Muldex kinematic coupling.The electronics is duet 3 with the new toolboard 1.1 with accelerometer. This thing is nice, you can tune your mechanics and even belt tension and also easy wiring. Bed I machined from 12 mm cast plate 5083 , and everything inside is metal , except for the belt holding brackets and tool board controller holder, that are both ABS printed prototypes yet.

So cost

45x45 and 90x45 profiles with brackets and connecting bolts and nuts - about 150 EUR

Linear motion including rails, bearings etc - about 240 EUR

Belts (GT2 9 mm , kevlar) with pulleys and idlers - about 100 EUR

Electronics - DUet3 + toolboard+ PSU+ SSR - about 300 EUR

Hardware - about 60 EUR

Panels - bond + acrylic 5 mm - about 100 EUR

Silicone heater AC 1600W - about 170 EUR

Spring steel sheet with magnet, custom from Energetic about 90 EUR + 50 EUR express delivery

Hemera about 120 EUR

Raw material for machining about 90 EUR

Machining CNC about 30 Hours

3 weeks later it was printing 🙂 The enclosure can hold about 60 deg inside so no warping at all on big parts with ABS

RE: Recommendations for a 3D printer with build area of 400x400mm or greater?

@marto

Nice printer, but the video does not load.

--------------------

Chuck H

3D Printer Review Blog

RE: Recommendations for a 3D printer with build area of 400x400mm or greater?

@cwbullet

Sorry here it is. The noize is from EDM sinker working on the back

RE: Recommendations for a 3D printer with build area of 400x400mm or greater?

@marto

Nice. It's hard to discern much from your youtube link, but maybe you can post something more in-depth and maybe even start selling them! Or, if not that, maybe post it as a project on github or similar.

Meanwhile, a review of the rat rig, mentioned earlier in this thread, has come out:

Looks promising.

RE: Recommendations for a 3D printer with build area of 400x400mm or greater?

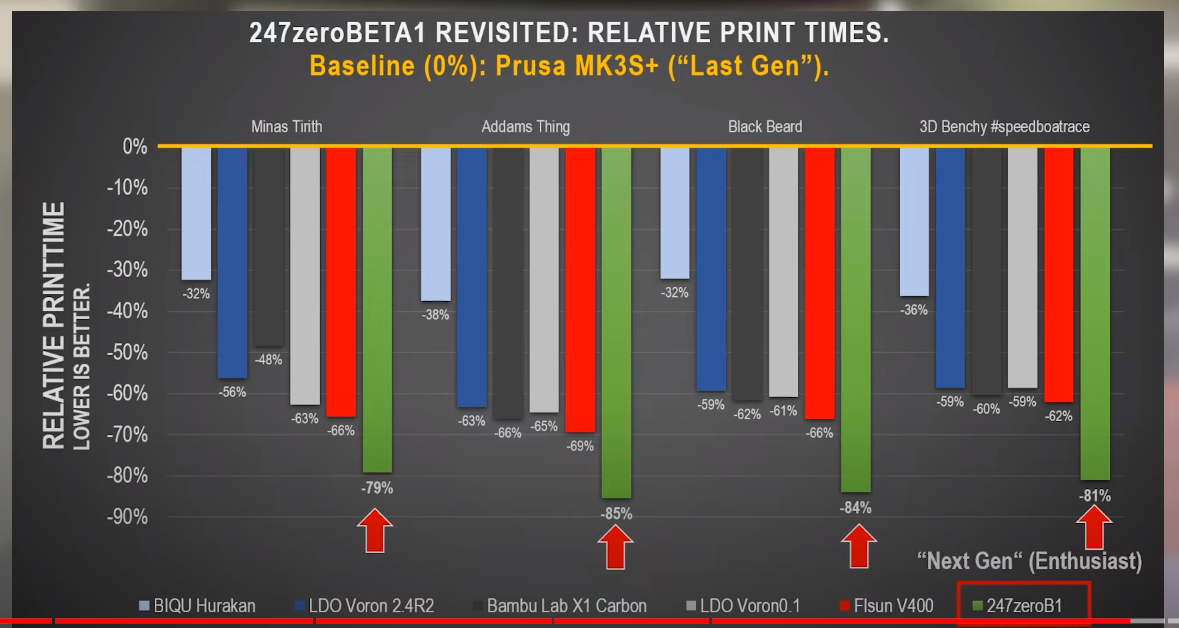

He hasn't yet done a proper review of it, but he did do a benchy speed test, and it looks to be insanely fast:

update

The Teaching Tech guy's benchy (directly above) took 8.5 minutes to complete, which I thought was impressive... that is until I noticed someone completing their ratrig benchy in just 5.5 minutes:

Supersonic

The Teaching Tech guy's benchy (directly above) took 8.5 minutes to complete, which I thought was impressive... that is until I noticed someone completing their ratrig benchy in just 5.5 minutes:

That is supersonic.

--------------------

Chuck H

3D Printer Review Blog

RE: Current list and comparison of high speed contenders

As pointed out by straylit on the Prusa XL thread, the vzbot is also doing a 5.5 minute benchy on a homemade "vzbot," but at a better quality:

Not sure what the vzbot build volume is. Anyone know?

There's a nice comparison of the different high speed corexy printers (voron, hevort, ratrig, vzbot) here: https://www.reddit.com/r/3Dprinting/comments/n1qahl/which_corexy_to_go_for_voron_hevort_vez3d_ratrig/

Summarizing: Sounds as though vzbot might be a winner in the long term because it's simpler and cheaper and has fewer parts than the others, but according to the reddit thread there's only just some cad files if you want to build one right now. Voron is the most compact design, but it's the most expensive and not the fastest. Ratrig suffers from a 6 week backlog, but (aside from lack of compactness) seems to tick a lot of the boxes. The thread didn't have much to say about Hevort, other than it's very fast but has a relatively small community.

ratrig

My concern about the ratrig is that even for the money, it' still not a 100% complete kit. In particular, there's some kind of backing plane that you have to source locally (the same one that Teaching Tech had to custom cut on his lowrider CNC). Given that it's a for-profit venture, the lack of completeness is a bit disappointing.

As for the Voron, I'm not sure whether any of the available kits off of aliexpress are of high quality. I've seen reviews of some of the kits, and the quality just wasn't there. Of course, you can opt to source all your own parts if so inclined.

And the build volume on the SECKIT SK-TANK is only 300x300mm, so it's way too small to meet my criteria. Sadly, the SK-GO, which came in larger dimensions, is no longer avaliable.

So, there's trade-offs no matter which design you might pick.

tool changing

Sorry for the multiple posts. Unfortunately, the edit time allowed on posts is ridiculously short.

Anyway, a pretty good article that considers these and some others is this: https://3ddistributed.com/corexy-3d-printer/best-corexy-3d-printers-2021/ A number of the ones it mentions are automatic tool changer capable, and since that' the future, maybe for futureproofing it make sense to give some weight to that feature.

reporting back

Reporting back: it turns out that the vzBot is just a heavily modified tronxy x5s corexy printer. It looks as though the secret sauce may be replacing the carriage beam with a carbon fiber beam, thereby making it much lighter. The key to the high print speeds for the 5.5 minute benchies seems to primarily be making the print head and associated assembly be as lite-weight as possible. Regardless, given the tronxy pedigree, I don't think the vzBot is for me.

The rumor on redit is that the voron has vibration issues if you try to extend the design up to 500mm build volume dimensions. It was also rumored that the belts for a 500mm^3 corexy get to be too long and stretchy. AFAIK, the only one of the 3D printers considered here on this thread that can claim a 500x500x500 build volume is the ratrig, and so I wonder whether it may have any of those issues as well. I haven't yet seen a any of the 500mm ratrig versions fully built yet, let alone reviewed, so I don't yet know. However, one youtuber is close to finshiing his 500x500x500mm ratrig, so maybe within a few weeks we'll have more insight into whether or not the ratrig design scales up well to 500mm without issues.

brute-force rigidity

One innovative trick used by the vzBot desiger (Vez Simon) and that's worth calling out was to anchor the vzBot frame directly to the frame of his house. The result, he said, was an extremely rigid printer that also damped down vibration. So, kudos to Vez Simon, for demonstrating this. It seems like an inexpensive, yet highly effective brute-force technique that could improve just about any 3D printer.

RE:

Well, none of these printers fit the size requirement, but, regardless, I think the lesson here is that Klipper (or similar) and core-xy, as upgrades, makes a huge difference in printing real prints.

Prusa XL wasn't available to include in the roundup, but hopefully it will be comparably fast.