New to 3D printing, some questions before getting a new printer

Hello,

I am going to get a i3 MK3S+ that will be used to make small accessories for a larger assembly. Main goals are to avoid milling time, get a more reliable part quality, and support.

The machine will be used to print less than 200 parts per year. Part size is about 3 x 3 x 2 in (76 x 76 x 51 mm) with its thinnest section is about 0.0625 in (1.6 mm). Smallest hole will be about 0.094 in (2.4 mm) diameter. Larger parts may be built in the future if this machine is viable.

I have a couple of questions before I make the purchase:

- Environment: This printer will work in a closed shed or garage. Will this printer be able to work in an environment that may heat up to 90 to 105F (32 to 40C).

- Material: I would like to use black ABS (or a material that has similar properties). I understand ABS filament requires extra care to work with. After checking the materials list from Prusa, would black PETG be a good replacement? Printed parts may be briefly exposed to oil, moisture, sun, and alkaline battery leaks. They may also experience some light impacts and scratches. Structural strength is not as critical because they will be attached, using stainless steel hi-lo screws, to much larger molded ABS parts. Parts will be visible so a smooth finish will be nice but it is not a deal breaker.

- Any must-have accessories that I should be considering with the printer? Like what sheet to get. I think it is the powder coated one but I am not sure. How long do print sheets last?

- Are compatible filaments easy to obtain in the US or do I have to order them direct from Prusa?

Thanks for your attention.

RE:

Hello @user100 and welcome to the forums.

The MK3S+ is a very capable machine and can easily achieve the dimensional accuracy you require, using the standard 0.4 mm nozzle.

Environment:

The printer should have no trouble operating in the environment you describe, however the quality of your prints may suffer if you have little or no control over ambient temperature and relative humidity. Airflow around the printer and the printing part will also affect your ability to achieve successful prints with a given material. The better control you have over the printer’s environment, the fewer the number of obstacles you’ll need to overcome to generate consistent quality prints.

Material:

Your printer will ship with a roll of PLA included. If you’re new to 3D printing my advice is to use this material to learn the machine and how to tune it for optimal results. PLA is arguably the ‘easiest’ material to get good results with; it tends to be very forgiving. Start by getting the printer dialed in for the material with a proper Z height and solid bed adhesion. Move on to simple prints so you can understand what the printer is capable of and what a good print looks like. Learn to use PrusaSlicer and slice your own models to experiment with. If you want to try a couple of the pre-sliced gcode files included on the sd card that ships with your printer, go ahead. But be prepared for less than ideal results and an inability to properly debug the print because you didn’t generate the gcode yourself.

Once you’ve got some basic printer and PrusaSlicer skills down you can move on to other materials. PETG is a good next material to try as it’s relatively inexpensive, readily available from a number of quality manufacturers, comes in a wide variety of colors, is suitable for many working parts, and may meet your project needs. Many makers will prototype designs in an inexpensive material to work out dimensional details and identify problem areas in prints that may need tweaking, supports, design alterations, or special attention in the slicer; then move on to their final material choice once the kinks are worked out.

You’ll find there are plenty of people here with extensive experience with ABS, ASA, PC Blend, and other, more exotic filaments - I am not one of them so I’m not going to wander into the weeds on this topic other than to say these materials will be far less tolerant of temperature and humidity variation and drafts than either PLA or PETG. These materials all require special attention and generally need to print in an enclosure to maintain ideal environmental conditions. They will also generate unpleasant odors as well as VOCs so extra caution is also required for safety.

Accessories/Print Sheets:

When I ordered my MK3S+ a little more than a year ago, I had my choice of the smooth PEI coated sheet or the textured powder coated sheet. I chose the textured which turned out to be a serious challenge for this beginner. If you search the forums for textured sheet experiences you’ll find out what I mean. Long story short, I couldn’t get the PLA included with the printer to stick to that sheet for love nor money. Took me a while and lots of help from the good people on these forums to get it sorted but it all worked out. I think the smooth sheet is what’s currently included as the default. That’s probably the best to learn on with PLA. For other materials like PETG, I recommend the satin sheet. I’ve had stellar results with both PLA and PETG on the satin sheet with no release or adhesion agents required.

Filaments:

Finally, pretty much whatever filament you want to try is readily available in the US. Prusament is pretty great filament and I will occasionally order a couple spools for special projects. My go-to for every day printing is usually Overture PETG available from Amazon, generally at very reasonable prices. There are plenty of good filaments out there and the good folks here will help answer your questions about all of them. I believe Prusa now has a distributor here in the states so maybe shipping costs are more favorable from that channel.

Summary:

I hope there’s something of value to you in this post. Forgive me if I assumed incorrectly that you are fairly new to 3D printing and oversimplified things. Likewise, forgive me if I missed some key bit of information you are keen to know. There is always so much more to learn and know. And there is far more depth to each of the topics touched on than I can do justice to here and now.

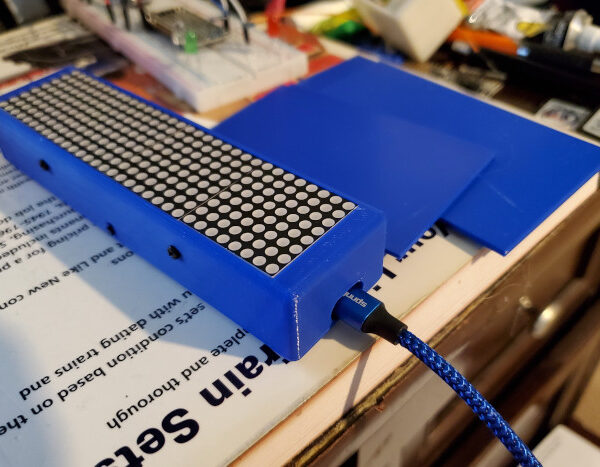

I still consider myself a beginner after about a year printing with the MK3. And I’m still amazed and delighted every time I pull a new print off the bed! My CAD skills are rudimentary (at best) but I continually find it astonishing that I can think up a part to solve a problem or repair a broken widget, sketch it, extrude it, slice it, print it, and hold it in my hand, all in the space of a few hours time!

Abso-freaking-lutely amazing! What a great time to be alive!

Cheers!

RE:

Higher ambient temperatures are actually much better for ABS printing, however, as cited, temperature consistency and lack of drafts are more important.

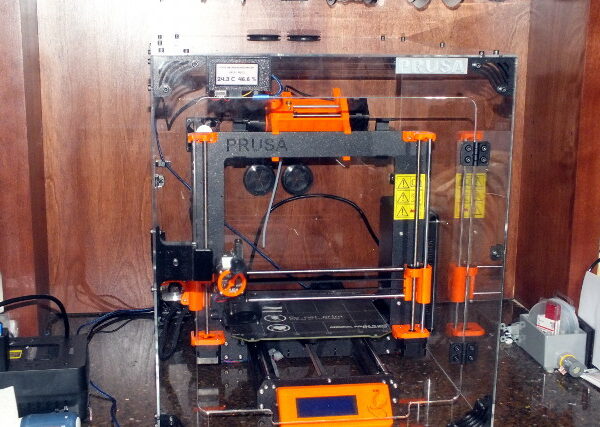

For any serious production work using ABS, you should consider an enclosure. I use, and like the one from 3d Upfitters (below), but I've added a (Pi Zero) controller to monitor the temperature and (attempt to somewhat) control that temperature. Many people prefer home-built or Ikea-based enclosures.

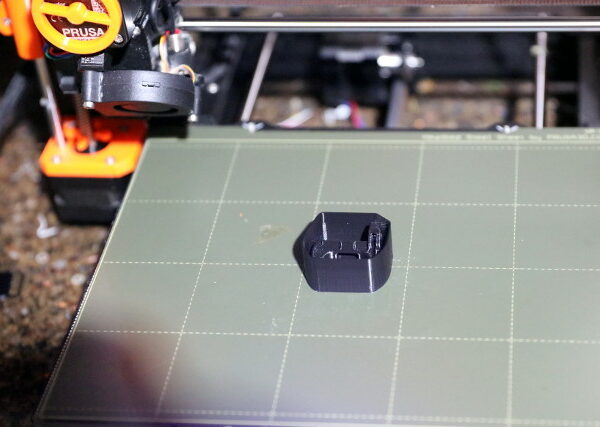

If you want to experiment with ABS before committing to an enclosure, the 'draft shield' option (shown below) is available on both PrusaSlicer and Cura, and provides a 'mini enclosure' surrounding the print.

The bottom two photos are of ABS prints that I've recently done. I've had mostly good luck over the years with ABS on the MK3S.

ABS printing requires more attention to detail than PLA or PETg prints, and I always suggest things such as:

1. Preheat the machine prior to an ABS print. Let things stabilize for 15-20 minutes or so.

2. ALWAYS use something like glue stick or Layerneer as an adhesion booster and release agent on ABS prints. (I learned the hard way on this!)

3. When an ABS print finishes, let the build plate and the print cool down to almost room temperature before removing.

4. Avoid the temptation to dork around with the various parameters and settings on the printer and in the slicer unless there is a specific reason to do so. The default values are the result of combined years of experience and millions of prints and are very well dialed-in.

As for PETg, I would suggest making test prints in ABS and in PETg and comparing. In general, PETg appears to be softer and not as good for details in the prints.

As far as Stateside sources, my go-to for filament is Amazon for a supplier, and my go-to brands are usually Hatchbox, Overture, Paramount, and a few others.

Specifically for ABS, I've had good luck with Hatchbox, RepRappers, and Polymaker.

There is a long thread here discussing various filament brands.

I've occasionally ordered Prusa(ment) but the to-the-door cost here in the States for it is high and it takes about a week from mouse click to the package hitting the door. Amazon is usually a few days, sometimes overnight.

A good second source (actually revealed as a first source) for many of the non-ment-suffix Prusa filaments, including the sliver-gray that comes with each new printer, is the US FilamentPM on-line store.

ABS is often, not always, cheaper than PLA or PETg. I recently got a kilo spool of Polymaker ABS from Amazon at US $15 and change to the door.

An i3 will meet your requirements easily.

machine will be used to print less than 200 parts per year.

No it won't. Once you have it you will find many more things to print... 🙂

ABS is no longer the filament of choice for a beginner, it can be tricky to print and generates some unpleasant fumes. You might like to check ASA as an alternative. PETG is much easier to print and will resist your chemicals well, it is susceptible to UV light 'though it takes several weeks for noticeable damage. If PETG meets your mechanical requirements it will probably be the better choice.

How long do print sheets last?

If looked after, years. If were you I would get a smooth sheet and a satin one. Many new users manage to damage one in the first week, luckily they have two sides.

Cheerio,

RE: New to 3D printing, some questions before getting a new printer

👍🏻

RE: New to 3D printing, some questions before getting a new printer

Good luck and enjoy the new printer!

--------------------

Chuck H

3D Printer Review Blog