RE: Multiple print failures

@tim-m30

X252 Y 282

A soft answer turns away wrath.

RE: Multiple print failures

The 252 explains the crash; you need to lubricate the bearings. The best way is to remove them, clean and pack with grease. You can mitigate the issue by adding a few drops of light machine oil on the rods and working the extruder back and forth until the axis moves more freely. But you'll need to keep up the oiling until you have time to do a real lubrication with grease inside the bearings. It would not hurt to oil both X and Y rods/bearings.

It may also be worth loosening the screws on the back of the extruder, the ones nearest the bearings, just in case they are clamping too tightly. A turn or two is usually enough.

Once the axis is oiled/greased and moving free, redo the self test and report back on new belt tension numbers.

Ideally, you want the numbers to be closer to 300 than 250; most folk with well lubricated bearings report 290 or higher.

RE: Multiple print failures

@tim-m30

Have oiled both x and y axes, and loosened the screws on the extruder as you advised. Now get X 272, Y 282. Maybe not ideal but I would prefer to get involved in dismantling the printer.

What next? Do I try to print again, or should I do a cold pull first to clean out the system?

Thanks again.

A soft answer turns away wrath.

RE: Multiple print failures

272 could be acceptable I have it as well.

Clean out would be preffered, but just try to preheat the nozzle using higher temperature (preheat is a menu item ) and request the filament release/pull out from menu. You will see whether successfull or not.

If not than probably the disassemble would be required.

If yes try to load a new filament watch the filament replacement , you should see the new filament flowing out of nozzle. And then try first layer calibration.

Then let us know. During first layer calibration watch the nozzle temperature variations on display.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Multiple print failures

@zoltan

"try to preheat the nozzle using higher temperature (preheat is a menu item ) and request the filament release/pull out from menu. You will see whether successfull or not."

Sorry, I'm not clear what you mean here. Is this part of the "cold-pull" process? Or is it something different? If so, I assume I load filament, and then do "pre-heat". But I can't find filament release/pull out from the menu- or do you mean unload filament?

Thanks

A soft answer turns away wrath.

RE: Multiple print failures

@epzcaw

Sorry for previous mail, I had to be more clear.

I wanted you to check whether after the successful cold pull your filament load and unload works.

The first sentence was the advice to try a proof of filament load. As I have automated filament load pre-set I have to first pre-heat the nozzle and after that I only push the filament into the ho tend whole and filament pours out of the nozzle.

Questions:

1. does the filament load and unload work after the successful cold pull on your printer yet?

2. did you have a chance to chat with Prusa support and discussed your issue?

3. do you have SKYPE, so we could have a online chat - could be probably more effective?

At his moment I would concentrate on the filament jam, belt tension does not have any effect on it, it concerns the heating and cooling.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Multiple print failures

No apologies needed - your help is greatly appreciated.I wasn't sure about the belt tension issue, and its relationship to my problems. But there is certainly a problem with the extrusion process, which is presumably a hotend problem.

I haven't done anything yet but will now try to do a cold pull, and then try loading and unloading the filament. I will let you know what happens.

I'm a but reluctant to return to PRUSA support, and there is no continuity between different advisers and I get a series of unrelated peces of advice. So if you are happy to advice me, I will carry on from here.

I could certainly do a Skype chat. Let's see how things go.

Regards

A soft answer turns away wrath.

RE: Multiple print failures

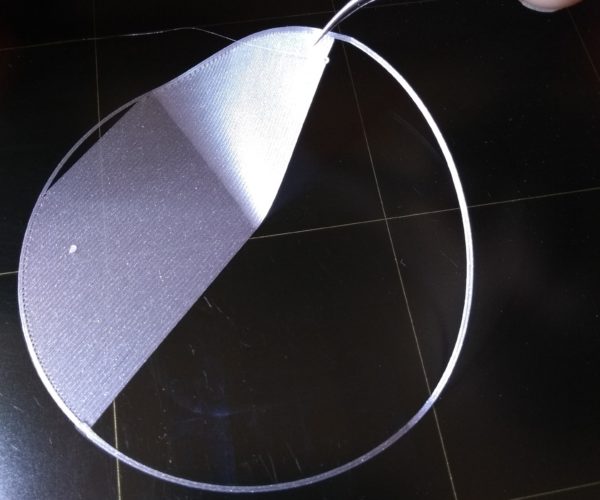

Cold pull successful - see picture. Looks fine to me.

Loaded and unloaded filament successfully.

Do I now try a first layer calibration?

Cheers

A soft answer turns away wrath.

RE: Multiple print failures

Did the 1st layer calibration. First two were not great, but the third one looks good, I think. Got a good z-value.

What next?

A soft answer turns away wrath.

RE: Multiple print failures

I am not fond of the built-in calibration.

There are a bunch of calibration circles. Maybe take one from this topic: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/paged/1/

If you do this, post your result. Maybe in a light filament so we can see it...

First layer should pretty much look like a smooth sheet. Yours does not. But them maybe I am just a photo critic.

RE: Multiple print failures

@robert-rmm200

Thanks for this. I'm reluctant to change filament, as it is yet another variable. But I will try one of the calibrations in the link.

Photo is not brilliant but it is actually quite a smooth sheet.

A soft answer turns away wrath.

RE: Multiple print failures

This is the point we need Tim to post his beautiful shot of what a calibration circle should look like...

RE: Multiple print failures

Also - current firmware versions support both the smooth PEI sheet and the textured one.

Set the sheet type correctly, and the firmware will keep track of the Z for that sheet type. Z varies drastically by sheet type. They are different thicknesses.

Other than that, PLA, PETG, or whatever should really not affect your Z setting. Get it right for PLA, for example, and it should be right (or close enough) for everything.

RE: Multiple print failures

Once the X and Y are moving freely, next comes the layer 1. All things in order :~). @epzcaw = the belt tension numbers tells us how well the axis move, the numbers shown represent motor currents required to push the axes around. They are meaningless for actual belt tension and must not be used to adjust the belts. The latest 272 is much better than 252, a good improvement and confirmation your bearings were indeed seizing up.

Since the extruder is extruding, we can move to Layer 1: I'm attaching my cal circles. Slice either one and print it. They are large enough you have time to make adjustments as it prints. You want to achieve a solid sheet of plastic, with no gaps between strokes, and no ridges where plastic flows up around the extruder.

This part is also good for checking adhesion. The circle should pull off the bed as if it were painters masking tape.

RE: Multiple print failures

I don't think first layer calibration is my problem. I have had many parts go most of the way through the printing perfectly, and then fail. While I'm not entirely sure why, it looks as if it is the filament stops coming out, or else the layers no longer attach. I will attach teo failed versions and a successful one.

A soft answer turns away wrath.

RE: Multiple print failures

That's the successful one. Now a failed one

A soft answer turns away wrath.

RE: Multiple print failures

After the dog failed, do an unload and post an image of the stub at the end.

ps: this is crucial: you must unload immediately after a fail - the tip of the unloaded filament is crucial for understanding what is happening.

RE: Multiple print failures

I did jeffjordan's calibration modle. See image. I've marked what I think is the best one.

One issue is that this was printing at 225 degrees rather than 215. Don't know if this is a problem.

A soft answer turns away wrath.

RE: Multiple print failures

Gentlemen let us concentrate on filament jam, which is the original issue leading to non completed prints.

Keeping tim's word hit one issue at the time, otherwise we can confuse the listener.

Summarizing the original issue short prints succeded longer failed due to the extruder stopping its task to extrude and getting filament jam.

One more i have in my mind how aligned are the bondtech gears.

@epzcaw did you have a chance to check it?

Extrusion can be blocked by any resistance which does not allow gears to move the filament down the nozzle.

- low nozzle temperature so the filament is not melted enoug - this can be due the non sufficient heat transfer betwen the heatblock and and nozzle or faulty heating of the heatblock - once it lead to change of the main board where the drivers were faulty

Let us try to find if this nis the issue.

This will require to start a print and if possible to record (on mobile phone?) the the nozzle temperature shown on the display

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Multiple print failures

The arrow is still a bit high. I'd have it squished a bit more (Live-Z more negative).