Exact Z size difference from smooth sheet to powder coated sheet?

Hello,

This is my first forum post 🙂

I ask because because I feel I have finally dialed in my Live Z as well as my Bed level adjustments. Well real test will be when I print using the whole bed because right now, I can use the middle and the front right with almost zero issues so I will see.

Anyway, I tried the powder coated and I tried adding -.200 to my Live Z -.280 for a new level of -.480 and it did not stick and made a mess.

i3 MK3S firmware 3.9 Prusaslicer 2.2

Thanks in advance

Jose Burgos

RE: Exact Z size difference from smooth sheet to powder coated sheet?

Hi Jose.

I don't know what you are trying to do...

it would appear that you have set Live Z on the smooth sheet, and then simply assumed that the Powder Coated sheet is a specific size difference thinner.

that is probably flawed thinking.

Let's assume that the base metal is exactly the same thickness for smooth stickered build plates and powder coated build plates...

and lets assume that we gauge the thickness of the stickered sheet with a vernier calliper, noting the thickness

we then gauge the thickness of the textured sheet. noting the thickness...

then we subtract the powder coated thickness from the stickered thickness, noting the difference,

then we divide the difference by two, and note the value...

Ok,

Let's assume the value IS actually 0.2mm and we add that to the Smooth sheet Live Z...

As I believe, you have done...

And it doesn't stick...

What could have gone wrong...

1, Powder coating is not an exact science. there is no guarantee that the deposition on each side, is the same thickness.

2, The calipers will have gauged the peaks of the texture. but the filament will try and fill the troughs... so we have probably underestimated the difference.

3, the Textured sheet may need cleaning... the textured sheet is often difficult to use at first...

I give mine a really good clean in the sink with dish soap and hot water, I rinse well with hot water, and dry immediately with plain paper towels... and this improves the adhesion, immensely...

anyway That is what I think you did... and you say it failed...

What I do, is to go into the LCD menu on the printer and

a, Make sure 7x7 Mesh Bed Levelling, is Activated!

b, set up different identities for my build plates I currently have PruSmo, WA-15 (One of my Prusa Textured sheets), Goldsmo and Goldtxt,

c, Run calibration prints for all four identities, and store the values against the identities. (I use Life Adjust 'Z' My Way)

Link https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/

d, Select the build plate identity appropriate to the sheet I am using for any particular job.

this way, I get good, repeatable live Z for all of the sheets mentioned

trying to offset thickness by guesstimation is not a good way to deal with different build plates.

GoldSmo and GoldTxt are chinese build plate sides I bought this, when Prusa sheets were in short supply and it seems to work well...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Exact Z size difference from smooth sheet to powder coated sheet?

Wow Joan let me say that was a well articulated and detailed explanation and I thank you very much. That helped me understand many things including creating the profiles/identities of different build plates which I did not know I could do 🙂

I will spend the afternoon tomorrow putting all this into practice and that thread you linked is amazing and extremely informative.

Thank you very much and I will report back on this thread my results

Take care, Jose

Jose Burgos

RE: Exact Z size difference from smooth sheet to powder coated sheet?

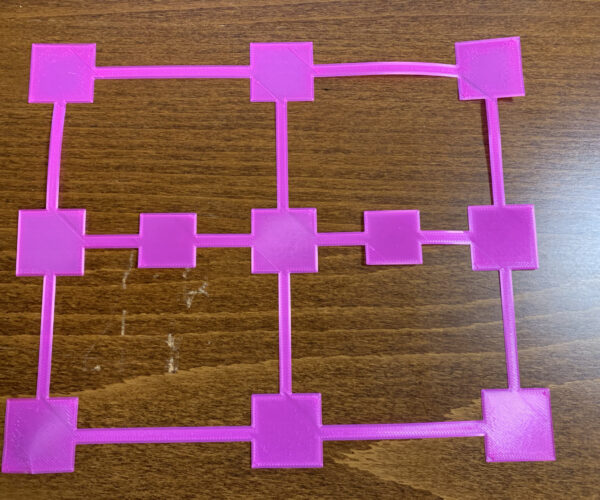

So after reading through Joan's suggestions and the thread Joan sent me from jeffjordan, I am first redoing my Smooth sheet settings and at .280 on my MK3S, this is what I get. Which I thought was good but after reading that thread, I can see I can fine tune it a little more as each square is being made, which I did not. I attached an image of this Smooth at .280 Live Z all the way through the print.

PS The file for this pattern does not fit as Slicer gives me the warning so I scaled it down till it fit.

On a side note, I washed my Powdered coated sheet with soap and water and did a First Layer setting and I only used the built-in Live Z and not this great pattern. I decided on .500 which was ok and then I cleaned the bed with Alcohol 91% (I have 99% being deviled soon in a spray bottle). But I went and took a chance and printed a file on the Powered coated after washing and it printed well at the .500.

As soon as I can, I will use the pattern on Powder coated and then fine tune Smooth and finally save them into the hardware sheet for each so changing is a breeze 🙂

Thank you for your help Joan,

Jose Burgos

Jose Burgos

RE: Exact Z size difference from smooth sheet to powder coated sheet?

Oh I just noticed I did not use the correct pattern and just download the correct one which is Bed Level Correction large. It fits perfectly in Slicer so now it's time to fine tune 🙂

Jose Burgos

RE: Exact Z size difference from smooth sheet to powder coated sheet?

Happy printing,

It's a learning curve!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Exact Z size difference from smooth sheet to powder coated sheet?

So I just wanted to share that I have for sure nailed down the Live Z level for the Smooth sheet and I am 99% on the Powder Coated sheet. I have their profiles in the system so all I need do is change the sheet, love this feature.

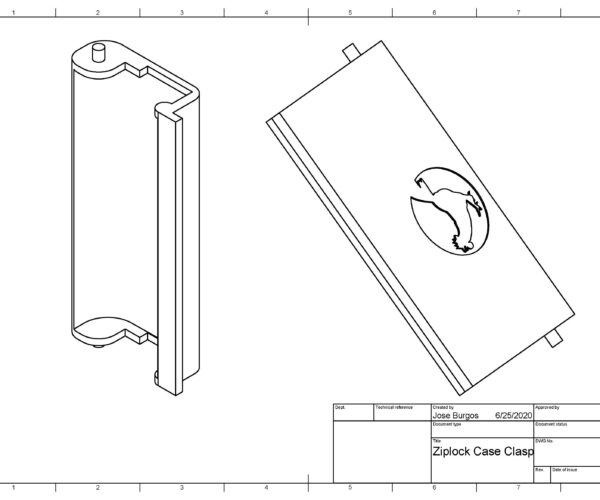

I also want to say that now that is out of the way, I am able to print anything I want which did not take long to push the envelope on that thought. I ordered some Zip Lock cases with a seal around the cover to store filament inside. It came in a pack of four cases. I filled them all up (I went crazy buying colors) but the last case was missing one of the clasp, needs four only came with three, to lock the top on.

So I went and measure one of the others and jumped into Fusion 360 (which I am still learning). This is the design I made;

I used translucent blue PETG to try and match the color of the other and It printed great.

I can not be happier so thank you again Joan for you help and all the people that post as I read many post and watch many YouTube videos to help my learning curve

Jose Burgos

RE: Exact Z size difference from smooth sheet to powder coated sheet?

Hi Jose,

you learned early on that Joan is a bottomless pit of knowledge and wisdom 🙂 It always pays to listen to her...