Burnt looking blobs when printing PETG

Hi all,

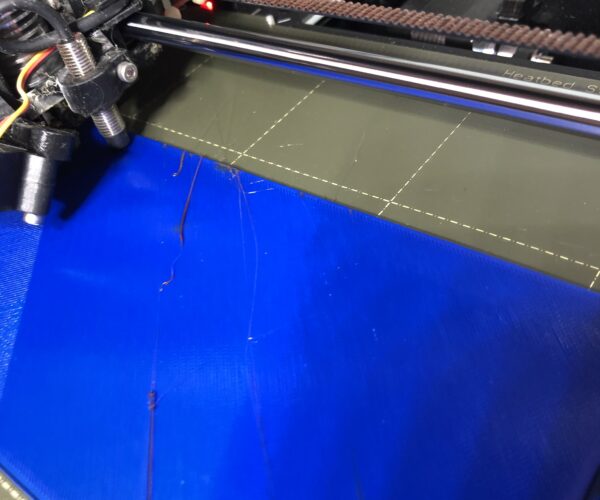

My i3 MK3S has just started producing burnt blobs which are now causing crashes - refer bottom photo. The hot end looks like it's 'leaking' somehow - refer mid photo. I did my best to clean up the hot end ( 1st photo ) but the problem comes back fairly quickly again.

What causes this problem and how do I fix it?

Many thanks in anticipation - Harley

RE:

It looks like you have a filament leak in the hot end.

Many people underestimate the amount of pressure developed in the hot end in order to force the molten plastic out of a fractional-mm hole, and if there's any other way for that pressurized molten plastic to get out of there, it will find it.

Most of the time the leak is along the threads, either of the nozzle, of the heat break, or both. This is usually due to a bad seating between the top of the nozzle and the bottom of the heat break.

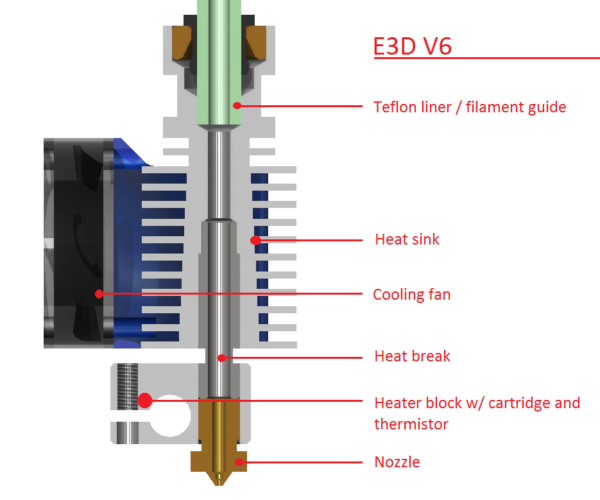

Below is a drawing of how things should be fitted. In particular, the gap between the head of the nozzle and the heater block is imperative!

If there is crud or debris between the nozzle and the heat break, the seal will be poor, and molten filament will ooze out of it, along the threads, and out onto your print. The nozzle may feel tight in this case, but it's not.

What you can do is to remove the nozzle, check the top surface to be sure there's nothing irregular, and clean it up with a fine file if needed.

Then you can inspect the threaded hole in the heater block, using a dental mirror and light if needed, and be sure that there's no debris in there that will prevent a good seal between the nozzle and the heat break. If the lower edge of the heat break has crud on it, you will probably need to disassemble the hot end to clean it up.

RE: Burnt looking blobs when printing PETG

Thanks JSW - that makes perfect sense.

I gather I'd need to do a cold pull before attempting to unscrew the nozzle - correct?

Harley

RE: Burnt looking blobs when printing PETG

Thanks JSW - that makes perfect sense.

I gather I'd need to do a cold pull before attempting to unscrew the nozzle - correct?

Harley

It wouldn't hurt. It may remove crud from the interior of the nozzle that might spill out and add to the problem during the process.

I have, however, seen one case where a so-called cold pull did not get everything out. This was with my other printer (Ultimaker) and it was obvious that there was something obstructing filament flow. I ended up disassembling one of the snap-in heater/nozzle assemblies and found a lot of scorched filament remains in the nozzle that needling and cold pulling did not remove.

I chased it out with a drill bit, mounted it in a vise, heated it up using a bench supply and did a couple more cold pulls that way, and finally tested to be sure the flow was unobstructed.

RE: Burnt looking blobs when printing PETG

Thanks again JSW.

Just as an experiment, I cleaned up the hot end a little better than what's in my photo and am running some good quality PETG. It seems to be going OK, but I'm only 40 mins into it.

I'm starting to think that the previous run I did with an unknown quality orange coloured PETG may have been part of or more the culprit. However, that wouldn't explain why one filament would leak and another wouldn't, unless there was a major difference in the constituency of the material.

Anyhow, once this print is finished ( if it gets that far! ), I'll get the tool out.

I really appreciate the time you've taken to help me out JSW

Cheers - Harley

RE: Burnt looking blobs when printing PETG

Did you change the nozzle recently? This can happen when the heater block moves against the heat bresk and creates a gap through which filament can ooze, as outlined by jsw. Check out https://help.prusa3d.com/guide/how-to-replace-a-heatbreak-heatsink-heaterblock-mk3s-mk3s-mk2-5s-mmu2s_16104 in case you have to partially disassemble the hotend and make sure the heat break is properly positioned and the nozzle pushes firmly against it and not against the heater block.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE:

Hi fuchsr,

No, I haven't changed the nozzle at all. I've only cleaned around it plus done regular ( every 200 hrs ) cold pulls and used the acupuncture needle for cleaning the nozzle.

Thanks for the link though, that will come in handy.

Cheers -- Harley

RE:

A follow-up question, did you have any cases of what's known as the Blob Of Doom, where a failed print caused a small or large blob of amorphous plastic to accumulate around the heat block and nozzle?

Usually those (if not terribly large) will release easily but leave residue on the heat block to scorch and drop on another print.

It's rare for a 'virgin' factory-assembled hot end to develop a nozzle leak.

I suppose that there could be a case where the leak is such that the viscosity of some filaments, but not others, would find the leak and flow out.

In the few cases I've had of this, it's been painfully obvious, however. It either leaks like a mother or else is solid and tight.

RE:

Hi JSW. With the latest print, I got 'The blob of doom' and it was less continuous, however it was still there and there is some sort of slow leak. It wasn't as bad a I had with the orange PETG. Yes it's a 'virgin factory-assembled hot end'.

I think I'll order a complete factory built hot end as a spare. It looks like a mission to replace, let alone try and find out the cause of the existing leak.

It's such a pity as up until recently, the machine has run very well apart from this problem gradually getting worse.

Thanks again for your help.

Cheers - Harley

RE: Burnt looking blobs when printing PETG

It''s really not that difficult to clean up a hot end and get it to near-new performance.

It's a bit awkward to remove the hot end from the extruder, but the basic procedure is shown in the link above.

You can then separate it into three pieces, the nozzle, the heater block, and the heat break and heat sink, which will usually unscrew in one piece.

The tricky part is to avoid damaging the connecting wires that go to the heater and the thermistor. Reasonable care works fine. Don't force anything!

You can then use a wire brush to clean up the heater block, or if there's a lot of scorched filament, a razor scraper can be used to remove it since most of it are flat surfaces. You can then 'chase out' the threads from both sides of the heater block using a nozzle.

Then you can clean up the mating surfaces of the heat break and the nozzle with a fine file.

I've always reassembled the hot end by starting with the nozzle. Screw it in to the bottom of the heater block, leaving a gap as shown in the illustration above. Then screw in the heat break and heat sink from the other side until finger tight. Then use a socket and a small breaker bar to snug up the nozzle. I use what I call 'two fingers' of pressure against the breaker bar. If you feel like getting fancy, you can use a commercial torque wrench or a printed semi-accurate one, but I've found that doing it by feel works just fine.

As long as the seal between the nozzle and heat break is good, it should not leak.

Then reassemble the extruder with the cleaned-up hot end.

You will most definitely need to re-do the Z calibration, starting with the rough calibration using a sheet of paper under the nozzle and a cable tie as a feeler gauge for the Pinda probe. Then use the internal Z calibration to get a nice oval 'bead' in the lines, and good square corners on the zig-zag, and a good degree of 'squish' on the square. Then dial things in further with one of those 3x3 single-layer calibration prints. You can make any fine adjustment to front/rear and left/right at this time.

Then it's time to print!

RE: Burnt looking blobs when printing PETG

Thanks JSW, much appreciated.

RE: Burnt looking blobs when printing PETG

I managed to get a phot of where the blobs are starting to build up.

RE: Burnt looking blobs when printing PETG

I managed to get a phot of where the blobs are starting to build up.

Yep, looks like a leak on the top of the heater block, filament oozing out of the threads of the heat break.

RE: Burnt looking blobs when printing PETG

Well, I guess that's good that we have finally ascertained beyond doubt what it is and what's causing it. It could also explain why the lesser quality filaments would leak more than others, perhaps due to a viscosity variances when they're at 240 deg C - who really knows.

Thanks again for you time to help JSW - Harley

RE: Burnt looking blobs when printing PETG

My suggestion for next steps would be to remove the nozzle, inspect the top surface for any debris that might prevent a good seal, and then inspect the heat block, using a dental mirror if necessary. (Most large pharmacies will have dental mirrors.)

You will then be able to see the threads in the heater block and the bottom of the heat break, and then get an idea of what may need to be done to correct the leak.

RE: Burnt looking blobs when printing PETG

Very good and valid hints from jsw!

One thing I would like to add, which helped me clean up a similarly messy situation: depending on what you've been printing, bathing everything in an appropriate solvent (if it can be legally obtained and safely used where you are of course) helps a lot with getting rid of residue. For me it helped a lot with getting the thread in the heater block clean again. I didn't notice that there was enough encrusted plastic in the thread to prevent the heat break and the nozzle from meeting and making good contact.

Also instead of using a nozzle from both ends, it is quite helpful to use a screw with the same thread, if it's long enough to reach all the way through it would avoid my mistake.