Z calibration failed! after build plate temp sensor replacement

Hi,

I'm struggling to calibrate my Prusa MK3, this printer has worked fine and printed during hours speciality it has printed smoothly hiundred's of face shield during the pandemic. Then I start to get a lot of cable issues and I had them replace the PINDA, both print head fans and the plate temp sensor.

Now I'm locked at the beginning of Z calibration step once the head moves close to the build plate it stops with a not really helpful message : "Calibration failed! Check the axes and run again". Please see the video below :

I did check the axis, the belt tension, etc and everything looks fine.

I did try to tweak the PINDA and at some point, I manage to get over the usual fail but then the head was scratching the plate and I got the error message: "XYZ Calibration failed. Bed calibration point was not found" please see the video below

I would appreciate any help

RE: Z calibration failed! after build plate temp sensor replacement

Check that your extruder hotend assembly is in the right place, and adjust your Pinda. I think it needs to go down a little

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Z calibration failed! after build plate temp sensor replacement

@joantabb

Hi Jonatabb,

I did check my extruder assembly and everything look good, I did adjust my PINDA hundreds of time and any time either the calibration stop when the head reaches the plate at the moment the PINDA detect the plate either the nozzle hit the plate and the calibration continues. This fill totally wrong at what point the calibration stop at the moment the PINDA detects the plate? isn't it the purpose of the calibration? also why after a fail calibration the screen is displaying 5.0 for the Z position?

I'm stuck here for month now, any advice to the exact procedure I should go through? I did everything I found, factory reset, firmware update,

RE: Z calibration failed! after build plate temp sensor replacement

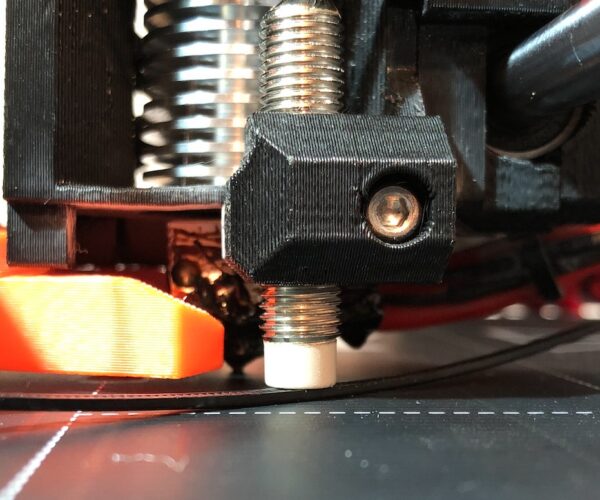

Can you let us see some pictures?

especially the gap between the pinda and the build plate, when the nozzle is touching the build plate

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Z calibration failed! after build plate temp sensor replacement

@targz

Hi Targz,

That looks Ok...

Does the LED in the top of the Pinda come on when the Pinda is in mid air, but go out when a piece of metal is held under the white tip of the pinda.

it should have a sense range of about 3 to 4mm

while you do this test also check the Pinda status menu on the LCD Menu. the status should toggle between 0 and 1 in response to the metal proximity...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Z calibration failed! after build plate temp sensor replacement

Hi targz,

I see the PINDA led flashing while moving, so I assume that the PINDA "more or less" work.

Since you dismounted lot of things on X and some Y to replace the PINDA and cables, there are some things to check:

- Check that the PINDA cable connector is firmly inserted on the board, since there may be a false electrical contact.

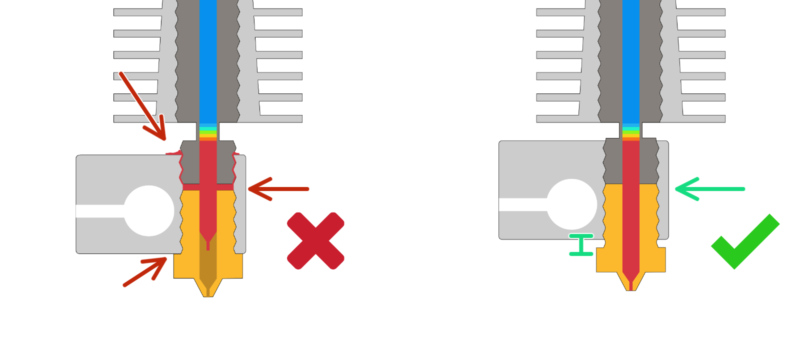

- Check that the height of your hot-end is correctly set! Follow the instructions at https://help.prusa3d.com/en/article/changing-or-replacing-the-nozzle-mk2-5s-mk3s-mk3s_2069 The gaps and distances should be correct as in the pictures, otherwise you may have an hot-end higher or shorter than the normal, and this causes the PINDA calibration to fail.

- Ensure you have the plate flatted, in case you played around with the bearings, changing the cables.

- Before you manually align the PINDA with the zip-tie, you should already be sure the X axe is aligned parallel as much as possible with the bed. So try to move around X and Y with a paper under the nozzle to see that your manually zeroed Z is correct, and then place the nozzle near the center area before putting the ZIP tie.

Let us know if any progress.

Regards

RE: Z calibration failed! after build plate temp sensor replacement

@joantabb I did check the PINDA and it is working as expected

RE: Z calibration failed! after build plate temp sensor replacement

@antimix

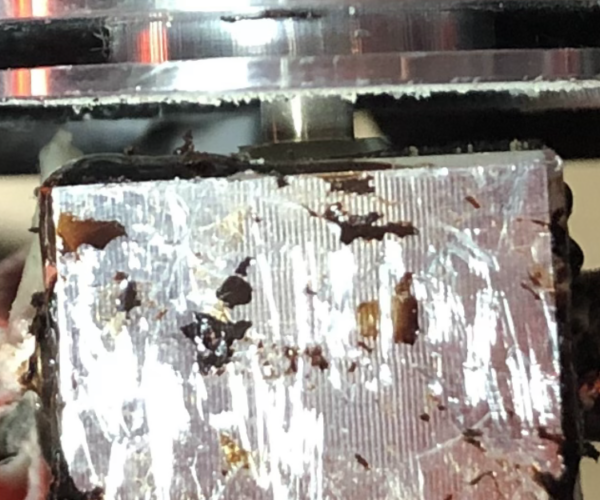

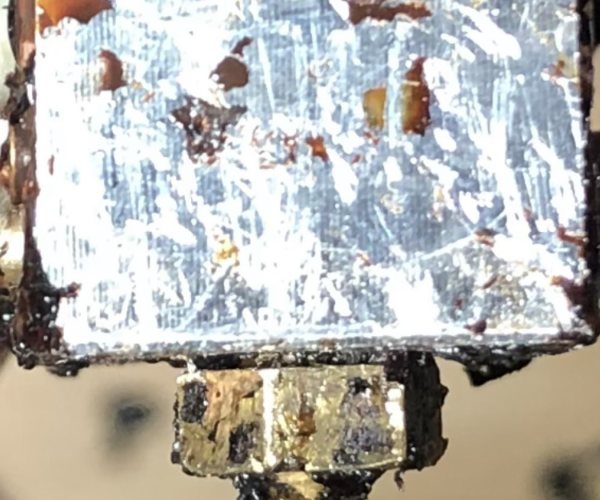

Hey thanks for the insigth, I did check my nozzle and in may be the issue, not sure about it but it looks like the gap is to small and I can see a part raising up in the top part.

What would be the procedure to fix this ?

RE: Z calibration failed! after build plate temp sensor replacement

Maybe this will help you ....

regards

https://help.prusa3d.com/en/article/changing-or-replacing-the-nozzle-mk2-5s-mk3s-mk3s_2069

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Z calibration failed! after build plate temp sensor replacement

@joantabb

Excuse me, do I have to replace the nozzle or just adjust it ?

RE: Z calibration failed! after build plate temp sensor replacement

Hi targz,

I see it worn out and dirty. Since you have to dismount lot of parts to fix your issue it, may be a good occasion to clean up well the hot block, and may be replace the nozzle. But is is up to you.

Regards

RE: Z calibration failed! after build plate temp sensor replacement

@antimix

Thanks you so much for your help,

but as the main issue for me is the calibration failure, I get that the faulty heigth of my nozzle may be the source of the issue, I did read the link on how to replace it but something is not clear to me :

Can I fix this nozzle position and how?

Regards

Still stuck

Hello,

I have change and ajust my nozzle as explained above and updated the firmware to 3.1.0 but unfortunately I still got the same issue.

I have been adjusting the PINDA and depending of it height I got 2 different issue at the bigining of the Z calibration when the head is moving closer to the bed for the first time.

1. "Calibration failed! Check the axes and run again"

OR

2. The Z calibration is going but the head is scratching the bed.

Can someone please could explain what is triggering that "Calibration failed" ?

Calibration failed

https://help.prusa3d.com/en/article/xyz-calibration-mk3-and-mk3s_112351

My understanding is the Z is measured from the top of the Z to where the pinda senses the print bed. If it is less than expected, then it will fail. I got this error on one printer and it was due to my pinda not being low enough or being too low. I cannot remember which. I also had it once with a faulty pinda on a different printer.

--------------------

Chuck H

3D Printer Review Blog

If you need to adjust the pinda probe, do this in very small steps, yes as little as possible.

Check extruder, the z axis and x axis, if at the back of extruder, if there is room enough to move the extruder all the way up and down left and wright. Cables could be in the way or tierap.

XYZ Calibration First

Hello, did you run the XYZ calibration? I’m new to all this and had a similar issue recently. I realized I needed to re-run the XYZ calibration before I could move forward. Good luck, hope you get it sorted.

strange behavior

So after hundred of PINDA tiny adjustments where if it too high the head catch the paper and if it's too low it stops with a "Calibration failed! Check the axes and run again" when the PINDA detected the plate; I tried to let the process go even if the nozzle was moving the paper. I finally found the 1st point and when it moved to the second point it was no more scratching the plate and it did all the other points just fine.

I'm assuming that it was adjusting the height for the other points, so I wonder why it could not do it for the first point.

The message "Calibration failed! Check the axes and run again" should be more detailed from a user perspective, it doesn't really help, it should describe better what has triggered the fail ( ex: witch axes)

Anyway thanks for your help, I will now try some print and update this thread.

Problem

This is one of two things: Your pinda is too high or you have a bad Pinda.

--------------------

Chuck H

3D Printer Review Blog

Firmware

Hello, I had the same problem, but solved it. I must have used the wrong firmware update. After updating the right one Z-axis calibration was no problem. You could give it a try.....