Wavy Walls

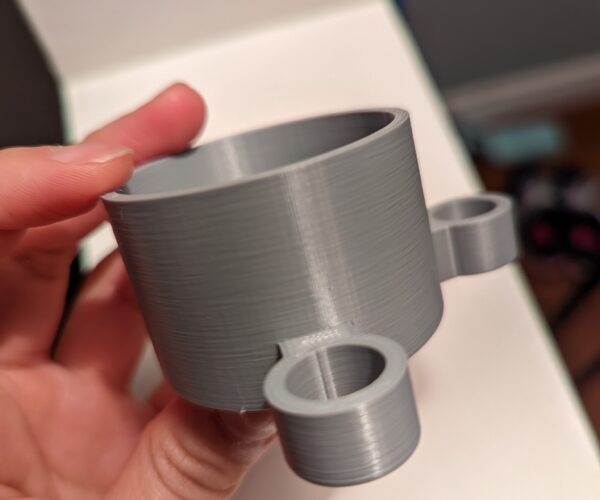

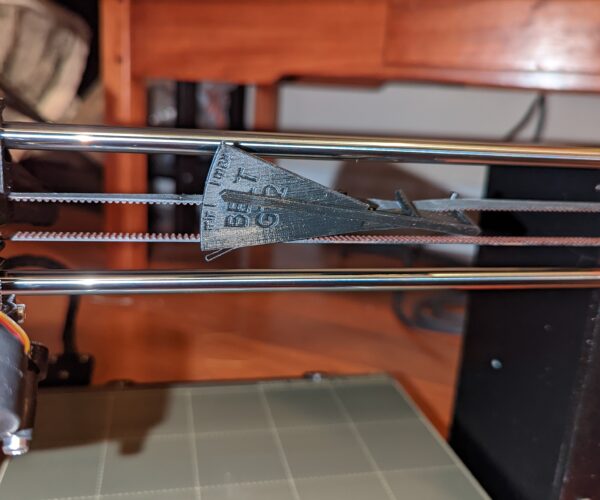

I assembled my i3 MK3S+ a few days ago and using PrusaSlicer default settings I get decent prints but no matter what I do I can't get the walls to be smooth. The picture of the grey print below is using 0.15mm QUALITY settings, with speed changed to 0.15mm/s for both small and external perimeters. It helped a bit but as you can see, there are still waves.

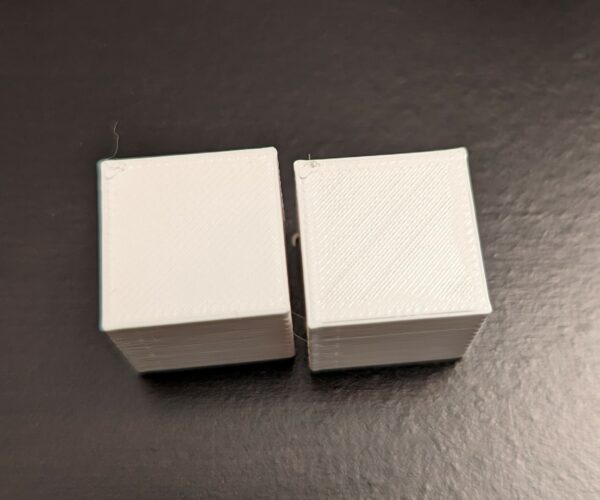

I'm pretty sure it is extruding the same amount - I printed the visualization cubes. The first cube on the left has extrusion multiplier of 1, and the one on the right was printed with 0.9 which starts looking like it's underextruded. I also measured the length of filament that was extruded manually, by marking the filament with a sharpie and going to move axis-> extruder and it is extruding the perfect amount.

I printed a temp tower 190 - 230 and they all are very similar (none had smooth walls).

I know it's not the filament because I used the exact same spool on my ender 5 and it prints fine..

I'm at a loss of what this could be, please help!!

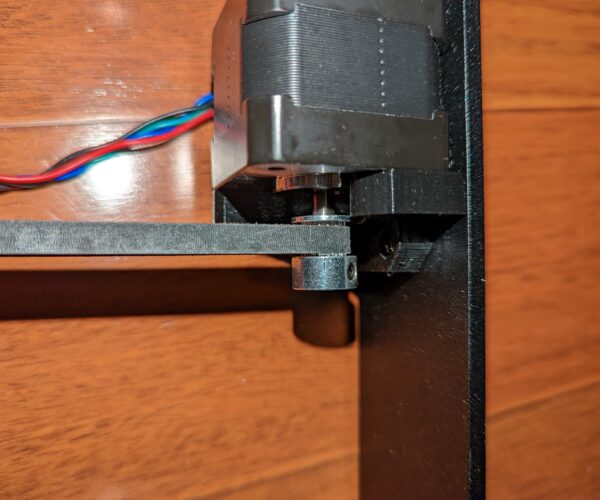

Check your belt tensions.

I think it's printing well enough to print this:

https://www.prusaprinters.org/prints/46639-tension-meter-for-the-gt2-belts-of-i3-mk3s-or-prus

It MUST be printed in Prusament PETG or the spring tension will be wrong.

Let us know how you get on.

RE: Wavy Walls

I did the belt tension test under Calibration and it was showing that the tension was fine... is this not usually accurate? Any idea judging by the looks of this if the belts are too loose or tight so maybe I can tinker around with it while I wait for my Prusament PETG to arrive? Thanks!!

The belt tension figure is a measure of the resistance felt by the stepper when moving the axis. On a correctly set up machine this does equate, roughly, to belt tension.

But other things can affect mechanical resistance. Sometimes they can disguise a poor setting. Ordinarily I would offer a list of tests and checks to try in order to get the printer running well enough to print the meter but your machine is already there...

Print some not-so-important objects while you're waiting for the filament.

Then let us know how you get on.

Cheerio,

RE: Wavy Walls

@diem I printed the tension meter with Prusament PETG and both belts are now properly tensioned. I also followed this to pack my bearings:

https://prusacommunity.com/set-your-bearing-straight/ and my machine does seem quieter now.

I checked to make sure my pulleys were tight.

I put my machine on a concrete paver in case it was the vibration.

None of that worked 😭

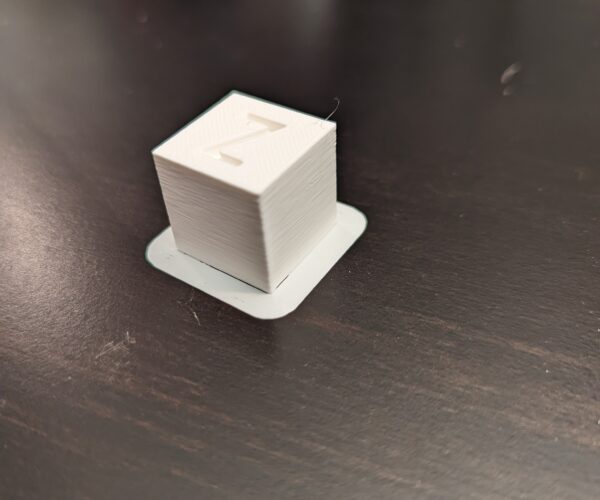

Here's my latest xyz cube print from last night:

Any other ideas??? Please help..

RE: Wavy Walls

I should mention that while walls still aren't smooth I think I see some improvement after doing all of that...

RE: Wavy Walls

ALSO forgot to add that I did a few cold pulls. There was just a faint brown colour on the first one, but the subsequent two pulls came out clean.

RE:

I would echo the suggestion to print out the tension gauge (using PETg) and checking (and adjusting if needed) both the X and Y tensions if needed.

Those printed gauges are not laboratory quality by any means, but they are more accurate than the 'bass guitar string' test or the internal test, which is influenced by many other factors.

It's difficult to tell from your photos, but the calibration cubes do appear to have some irregular layers typical of some kind of 'slop' or 'play' in the mechanics.

Another thing to check are the grub screws on the belt pulleys. Loose grub screws can cause irregular layers as well.

A general 'snug up' of the bolts on the build platform and the X and Y mechanisms might be in order too.

RE: Wavy Walls

Hi jsw, thank you for your reply!

I did print out the tension gauge with Prusament PETG and both belts are tensioned correctly.

I've checked the grub screws on the pulleys and they were tight.

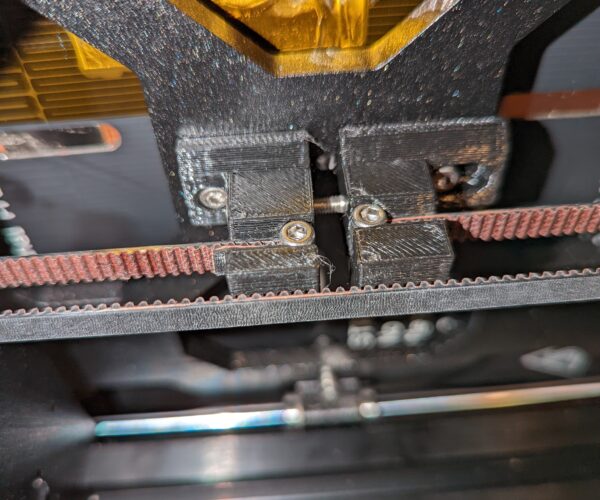

I am suspecting now it is because my belts are out of alignment but I can't fix it.

The y belt is rubbing on the y-belt-idler, and the x belt is rubbing on the x-belt-idler.

No matter how I adjust the pulley I can't get it to straighten out. I can get it so the belts don't rub on the pulley, but I can never get it to not rub on the idler. I've also checked the y-belt-holders and have made sure everything is tight and the belts are in place.

Any ideas??

RE: Wavy Walls

You say you know it isn't the filament because it prints fine on your Ender 5. I don't think that's really an appropriate test of the filament. The Ender 3 is a bowden tube extruder where the MK3 is direct drive. The bowden tube on your Ender 5 is 100mm or more from the nozzle and is going to act like a buffer and will even out the pressure the filament is under to a small degree, and what you're seeing here is to a small degree. The MK3 being direct drive puts the nozzle only 20mm or 30mm from the extruder motor, this allows it much more pressure at the nozzle. If you could test this against another MK3 and got different results that would be more meaningful.

You say you've checked the feed rate and it's correct, how old is this filament? It looks to me like uneven extrusion, others say check belts. If the belts are good, are we sure the filament is fresh and dry? I see many more artifacts as my filament ages. Also, what is this filament? Who made it? If the filament isn't precisely 1.75mm along its entire length but fluctuates wildly you could get unevenness at the individual layer level even though over 100mm everything seems to feed correctly.

Lastly what slicer are you using? It seems like many Ender users like Cura. I got my I3 Mk2 before I got my Ender so I strictly use Prusa Slicer. The reason I ask is sometimes Slicers create artifacts, I've seen weird things in my prints that I don't see in my slicer, yet I know it's the slicer that putting it there because I printed 4 of the same model on the plate and they all have the same artifact in the same place.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Wavy Walls

Are you seeing this on the x-axis, y-axis or both? You've checked the belt, are there any wobbles on either axis? Loose bearings? Loose screws?

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Wavy Walls

I'm seeing it on both x and y axis (all sides of the cube). The sides with the X and Y letters look good though, like barely noticeable. Not sure if that is telling of anything.

Ive triple checked that all the bolts and grub screws are tight. No wobble anywhere. And I tried pressing down and various places while the machine was running to see of the sound decreased didn't find anything so I'm fairly certain there's nothing loose. I also went around and loosened the screws holding the frame together, and screwed them back on tight while on a flat surface in case anything was misaligned. Didn't help.

RE: Wavy Walls

It's a puzzler. If that were off my Prusa Mini I'd say it's reasonably good print, but it's a Mk3 so it shouldn't be doing that. You've covered all the axis so now I'm thinking the extrusion may be uneven, but that's why we buy the I3 instead of the Mini. I guess at this point the only thing I can suggest is check the tension on the double gear assembly on the extruder, maybe it's too tight or too loose. If that doesn't do it, take it up with Prusa support, this should be under warranty.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Wavy Walls

Hi Bob, I think prusa support will be my next stop. I really appreciate the time you've taken to help, thank you so much!!

RE: Wavy Walls

Just wanted to update this thread in case it helps anyone. I contacted prusa through their live chat, they were amazingly helpful!

- The roll of filament that comes with the machine is NOT prusament. If you're getting similar prints with imperfect walls (although I do have to admit I am pretty picky - the imperfection only showed when you view it at an angle) I would suggest buying a roll of Prusament and trying to print with that before you start pulling out your hair and spending dozens of hours researching and tweaking your machine. When I printed the cube with actual prusament PETG (the one I bought to print the belt tensioner) it came out perfect.

- As Bob said earlier, bowden tube set ups are more forgiving of uneven thickness of your filament and I was able to get away with cheaper filaments on my Ender 5 but will need to spend a bit more for better quality filaments for my Prusa

- For using up less than perfect filaments on a Prusa, I recommend trying to increase the layer height. Using the default PrusaSlicer for 0.3mm DRAFT gives me acceptable results.

RE: Wavy Walls

I don't know if you already figured this out but I think I did. After a ton of testing, I found that it is caused by extrusion inconsistency with a few things that can trigger it.

1. If your bed and nozzle are not properly PID tuned. The slight fluctuations in layer height caused by the filament expanding and contracting can cause your line width to vary in seemingly random intervals. Similarly, slight changes in nozzle temp can make it slightly easier or harder to extrude filament. This can also change your extrusion width in similar ways.

2. (the one that causes most of mine) the filament spool pulling on the extruder. We switched to 3kg spools in our print lab and, almost immediately had this issue. After trying to figure it out for a while, we noticed that the spool would get pulled by the extruder, overshoot center, and rock for a second. If you keeps some slack in the filament, you can easily see if this is your issue. I designed a spool holder with a bigger center to try and keep this to a minimum.

3. The extruder idler gear. There is a great video from MirageC about this one. I converted one of your printers to be single drive with a smooth idler and it helped a lot.

That one printer has all of these fixes and makes beautiful prints. Bowden printers are much more forgiving because the slop in the tube damps the first 2 issues and gives more consistent extrusion since it covers up some of the inconsistencies. Checking different wall speeds can help a lot. I noticed that, for our printers, the extrusion consistency got much better at about 50mm/s or 100mm/s instead of 35mm/s. OrcaSlicer has a VFA calibration test that you can use to figure out what speeds you can run at. I hope this helps.

I assembled my i3 MK3S+ a few days ago and using PrusaSlicer default settings I get decent prints but no matter what I do I can't get the walls to be smooth. The picture of the grey print below is using 0.15mm QUALITY settings, with speed changed to 0.15mm/s for both small and external perimeters. It helped a bit but as you can see, there are still waves.

I'm pretty sure it is extruding the same amount - I printed the visualization cubes. The first cube on the left has extrusion multiplier of 1, and the one on the right was printed with 0.9 which starts looking like it's underextruded. I also measured the length of filament that was extruded manually, by marking the filament with a sharpie and going to move axis-> extruder and it is extruding the perfect amount.

I printed a temp tower 190 - 230 and they all are very similar (none had smooth walls).

I know it's not the filament because I used the exact same spool on my ender 5 and it prints fine..

I'm at a loss of what this could be, please help!!