Stringing issue after 2 Jears

Hi,

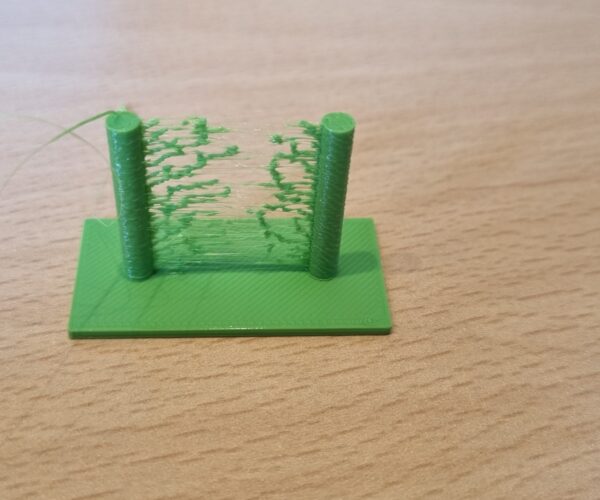

i have acvtually very hard stringing isues with my Prusa I3 mit MMU2.

I have no idea where they com from, i don´t changed any parameter and also an exchange of the nozzle don made the situation better.

Below you can see my old Nozzel, inside you can see rests of my white filament (is this normal???)

the diameter of the coole and the input diameter of my nozzle is a litle bit bigge then the filament (approx. 2mm in diameter).

Thanks in advance!!

Show the first layer to start

Could be a number of causes. Can you show the bottom of that green print please.

RE: From the bottom

Hi,

thanks for the fast reply,

i added the Picture from the bottom and a short Video from the printing.

A little sloppy

Not dialed in on live Z is my first suggestion. The lines are interesting - I think I can see a "wave" - the tell tale ripple of live Z too low - but at the same time, the lines are not squeezed together well enough - suggesting Z is too high. Let's try this. Take the file that you generated the GCODE from in the slicer - the saved project file (extension = .3mf) slice it, save the Gcode, Save the project. Then zip up the .3mf file into a compressed folder (zip it) and then use the Attach file button below (labeled choose file) to attach that .3mf file here ... that way we can see your settings, try the print and see if there are some setting changes to suggest.

Not dialed in on live Z is my first suggestion.

live z has absolutely nothing to with the described problem.

wet filament often leads to more stringing.

worn nozzles also cause more stringing. but if you already tried with a new one i guess thats not the cause.

different filament (batch)? might need some temp adjustment, higher hotend temp also leads to more stringing

Did you change filament from green filament to white filament?

End of knowledge

Hi,

i changed the Nozzle, the PTFE-Tube which is in the Cooler, i readjusted the Temperature-Sensor and the Heater in the Heatblock, I cleaned the Filament Transport "Bearing" and i opened a new roll of Filament. After all of this i´ve done all calibrations at the Printer.

I´m really absolutely lost why this started to happen and how to solve.

I also checked that the Filament is getting retracted.

I ´ve done a Video from the printig, but can´t integrate it into the post.

Do you have YouTube account? You can use that and add link in here.

Video

Hi,

i added the video to YouTube (my first YouTube Video;-))

I think @xenon is right, you have damp filament. In many parts of the world this has been an unusually humid year and we are seeing a lot of this sort of problem.

Look up threads on here about drying your filament.

Cheerio,

That filament is damp as well, and your first layer Z calibration is a fraction too low.

Cheerio,

maybe the temp is off. higher temperatures lead to more stringing/oozing, and prusa's resommendation for their petg is already rather high. try printing a temp tower.

my recent spools of pruisament petg arrived in damaged bags from rough handling of the boxes, maybe take a look at yours too.

or try contacting pruisa support/chat, maybe they know more.

Temperature

Hi Xenon,

i think the Temperature is a good hint, i will test the Temperature Probe with icewater and try coocking water.

My Prusament spools arrived in an excellent state with no demages.