Second layer problem

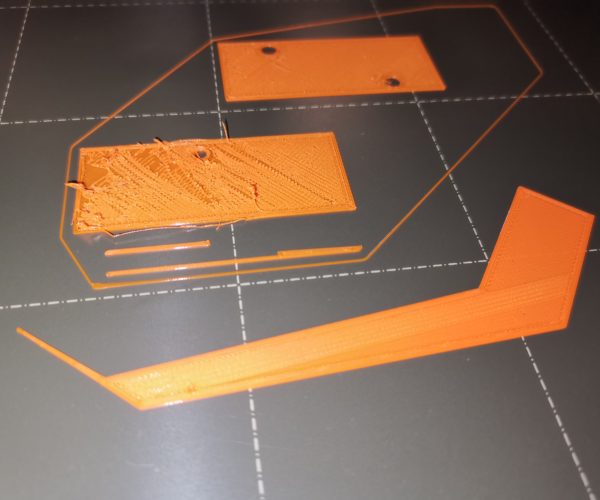

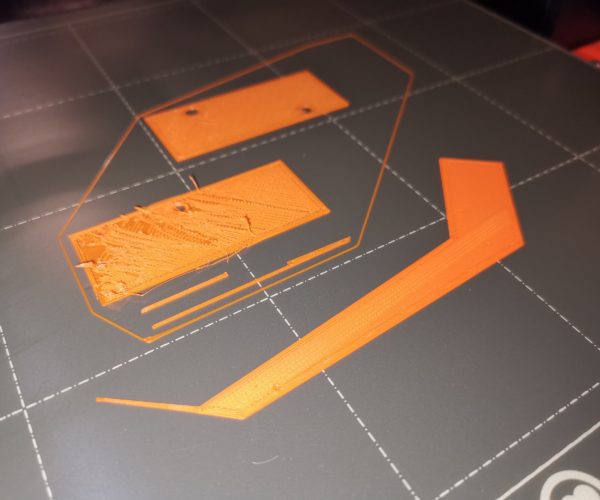

So first layer as You can see looks ok for me but second layer is not stickingn I had this issue with standard batman logo gcode that was on sd with printer.

This was my stl and profile was ultra quality 0.05.

RE: Second layer problem

I think you will need to give more information:

Filament

Nozzle

Bed and extruder temps

.05 is - small... Try it again at .15 Quality.

RE: Second layer problem

@robert-rmm200

Sorry, my printer is bone stock freshly assembled.

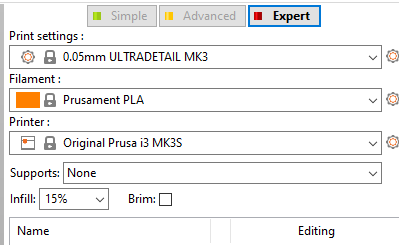

I have stock 0.4 nozzle and Orange Prusament. I used ultra quality profile that came with Prusa Slicer 0.5 and temps in this profile are set 215/60 i think.

I basically did not change anything beside choosing profile.

I also had same issue with batman logo gcode that came with printer, I belive it was set to 0.2 and same temps

RE: Second layer problem

So now I tried the same stl but with 0,15mm QUALITY MK3 profile and had the same results... btw printer is placed in closed enclosure.

I am trying to print mainly this https://www.thingiverse.com/thing:3271753

I hope that I am doing something wrong because if this is how MK3S printing looks like I am shipping it back, and fast 🙂

RE: Second layer problem

Good luck shipping back an assembled kit. You will find plenty of examples on here of the excellent work the MK3S is capable of.

What is the temperature inside your enclosure during printing? Enclosures are great for PC or ABS - not so much for PLA or PETG. I would keep the door open...

I would start with trying a different filament.

If it prints the same, post a picture of your first layer calibration square (or circle).

Start with this writeup:

RE: Second layer problem

Good luck shipping back an assembled kit. You will find plenty of examples on here of the excellent work the MK3S is capable of.

What is the temperature inside your enclosure during printing? Enclosures are great for PC or ABS - not so much for PLA or PETG. I would keep the door open...

I would start with trying a different filament.

If it prints the same, post a picture of your first layer calibration square (or circle).

Start with this writeup:

I don`t see any problems with returning it - https://help.prusa3d.com/article/x6lxmh2nz1-packing-printer-for-return

As for print quality, I don`t want to start any fights here, I know what the machine is capable of but I think that people, at least I pay extra for Prusa to have sure and hassle free printing experience. So far as for assembly it was really smooth but this printing thing is a problem.

I wanted to avoid searching forums, tinkering and troubleshooting with this printer but I will try in the evening calibrating first layer according to this guide although for me this look more like under-extrusion rather then first layer problem but i will give it a try.

I will disregard comments about enclosure and changing filament - Ender 3 was printing in the same enclosure with cheap ass filament without problems when it was working 🙂

If someone have other suggestions, maybe settings I can change I am open for comments - I did calibration through wizard after assembly and that`s all I did.

RE: Second layer problem

You never mentioned material you are using. You just said "prusament orange" which could be PLA, PETG or ASA. Your image shows the PLA profile selected, which will likely give these results if you are actually using PETG from too low a temperature.

I will disregard comments about enclosure and changing filament - Ender 3 was printing in the same enclosure with cheap ass filament without problems when it was working 🙂

If you're going to ignore diagnostic advice from the people here, why are you even posting for help? Just because something works on one setup does not make it a universal truth. You are basically making your own life harder by refusing to eliminate possible causes. If you are using PLA, the Mk3 design is such that you basically *will* have problems with PLA in an enclosure.

RE: Second layer problem

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Second layer problem

I guess I indeed did not clarify that I am printing with Orange Prusament PLA that was included with the printer.

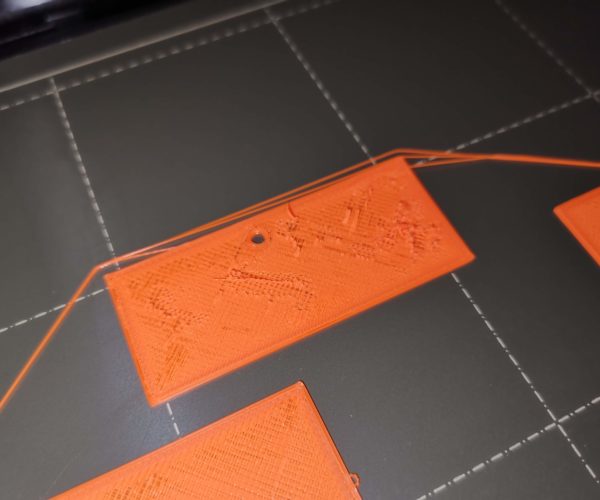

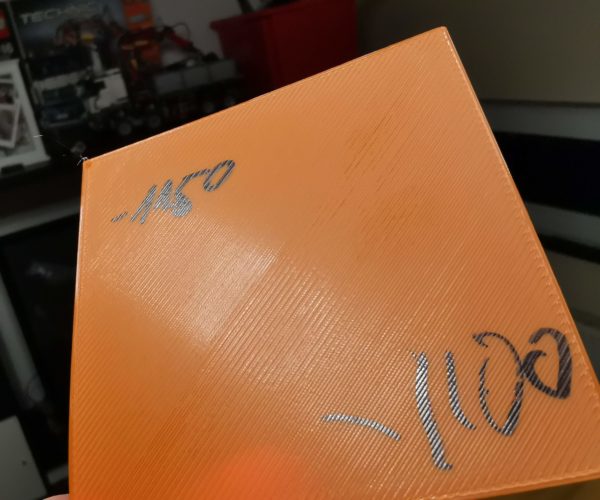

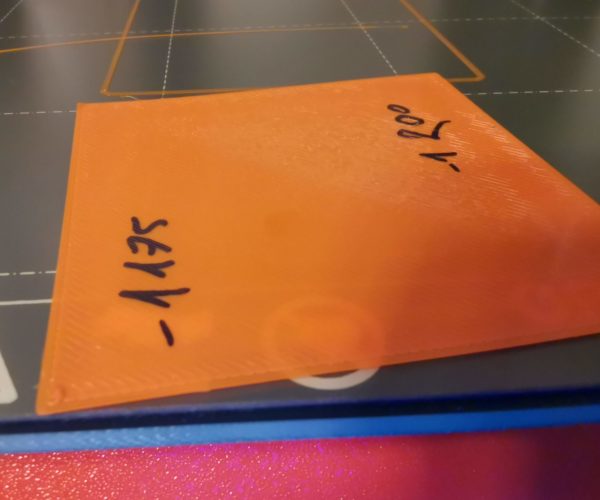

With printer moved out of enclosure I am getting similar results. First layer is set to -1150 and it sticks really well but the second layer has some strings that are getting up and does not stick although this time not so many as before.

I also had readjusted PINDA and had run Wizard calibration again.

Below are my squares - currently -1150

RE: Second layer problem

I meant not so many lines of the second layer are not sticking to the first layer as before

RE: Second layer problem

Those pics look pretty good, certainly compared to your first batch. You could try reducing the cooling fan after the 1st layer as a quick test. Normally, the basic profile settings are good for PLA.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Second layer problem

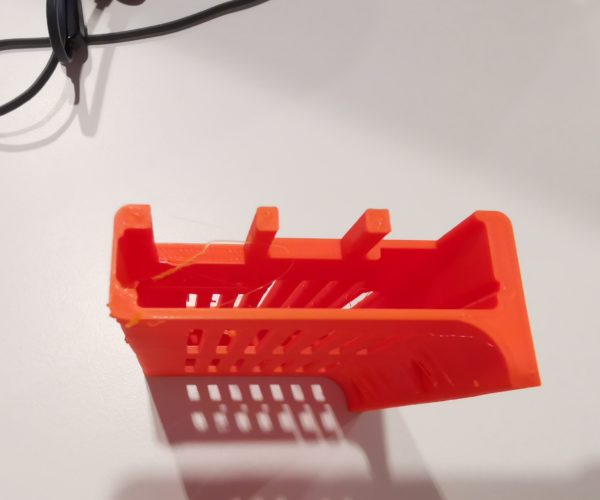

Ok so this is how a bigger print looks like, how will you call those imperfections? It also brake in hands as You can see.

I guess it is time to start new thread in print problems?

RE: Second layer problem

This is exactly what my print does when I mistakenly slice with PLA and use PETG filament. The first layer prints ok, but the second layer has a hard time sticking. For anyone else experiencing this, make sure you are slicing with the correct filament type.

RE: Second layer problem

@spencer-o2

Pretty sure the fillament that comes with the printer is in fact pet?

RE: Second layer problem

Hi,

Mine was a grey and sparkly PLA filament.

I would check the slicer settings to be sure of proper values, and maybe try a different spool of filament if one is handly.

RE: Second layer problem

@spencer-o2

Literally decided to make my first post just to thank you for this. Was having trouble getting second layer to stick to first and kept looking at all this tiny variables. "Should I slow it down? Change the temp? some weird other setting?"

After reading your comment I was like... "wait, the stuff I think is PLA and sliced with PLA settings really is PLA right? Turns out I had the PETG roll on. I feel dumb.