Prusa demos print great, but things I slice... not so much

Hello!

I just built my MK3 kit last week and I didn't have any setup issues. I printed several of the models on the SD card, and they all look fantastic (Benchy, gear bearing, Prusa logo, Batman, whistle, etc.). So I believe my printer is generally functioning well.

However, I'm having trouble with several models I've downloaded and sliced myself. The first layers seem continuous and generally "stick", but the printing is inconsistent and not reliable.

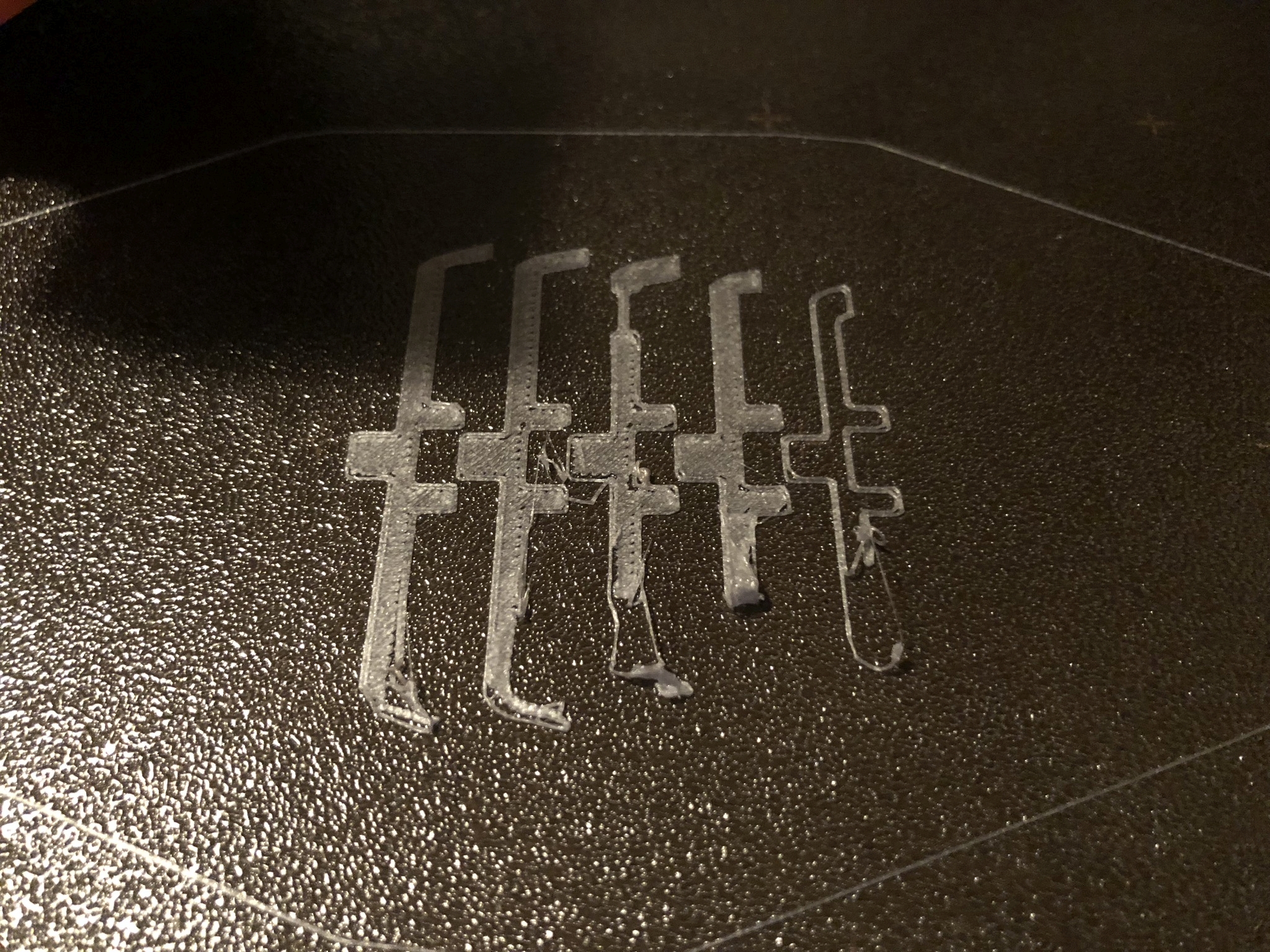

I've attached three photos that demonstrate my problems. The first one is one of the MANY failed attempts to print the "Save Pangolins" from Thingiverse. The first layer will not print completely.

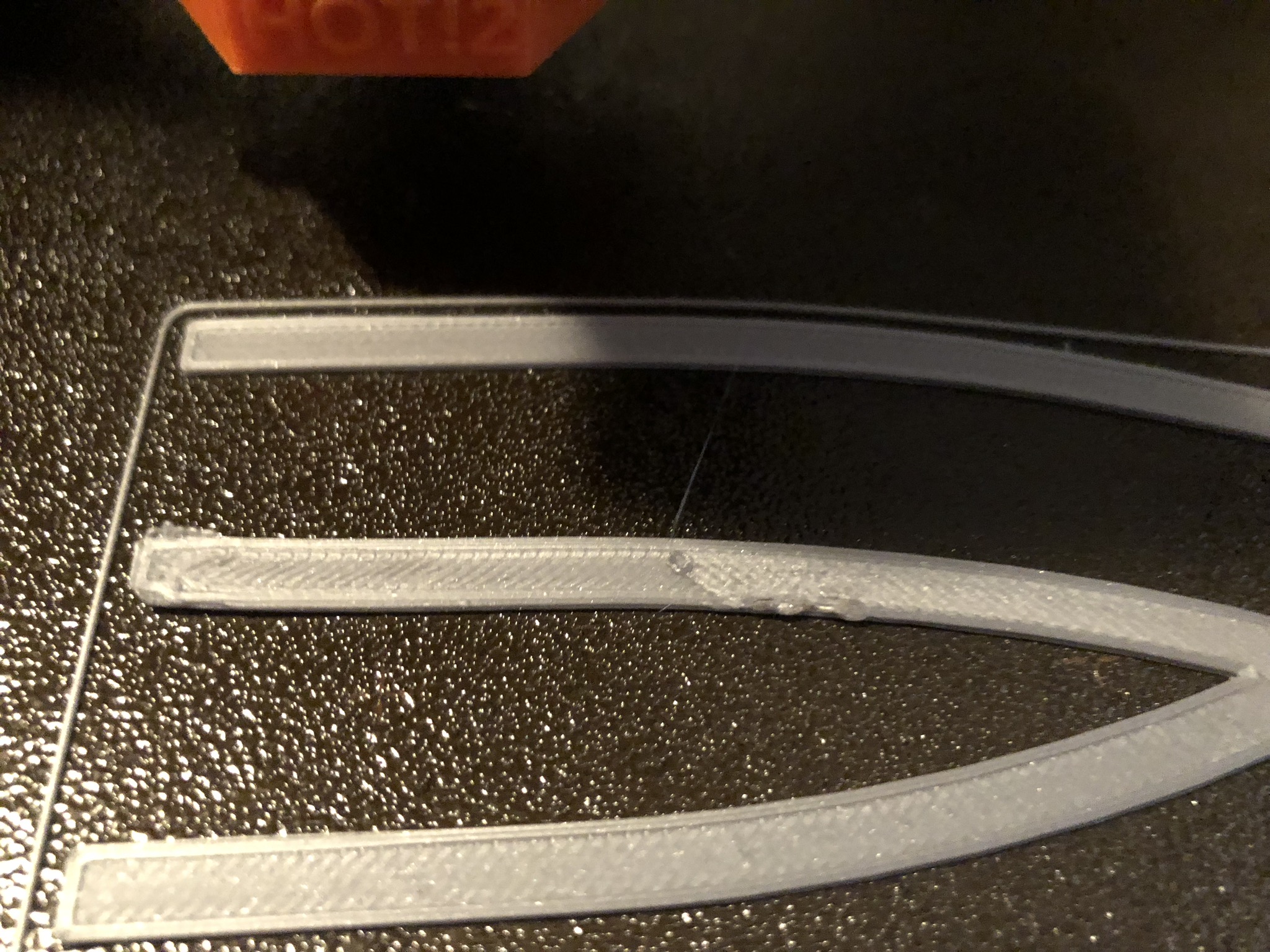

The second one shows how the first layer of another model is often rough, with "blobs" of plastic deposited by the extruder. When the following layers print, the roughness interferes with the nozzle and causes the print to detach.

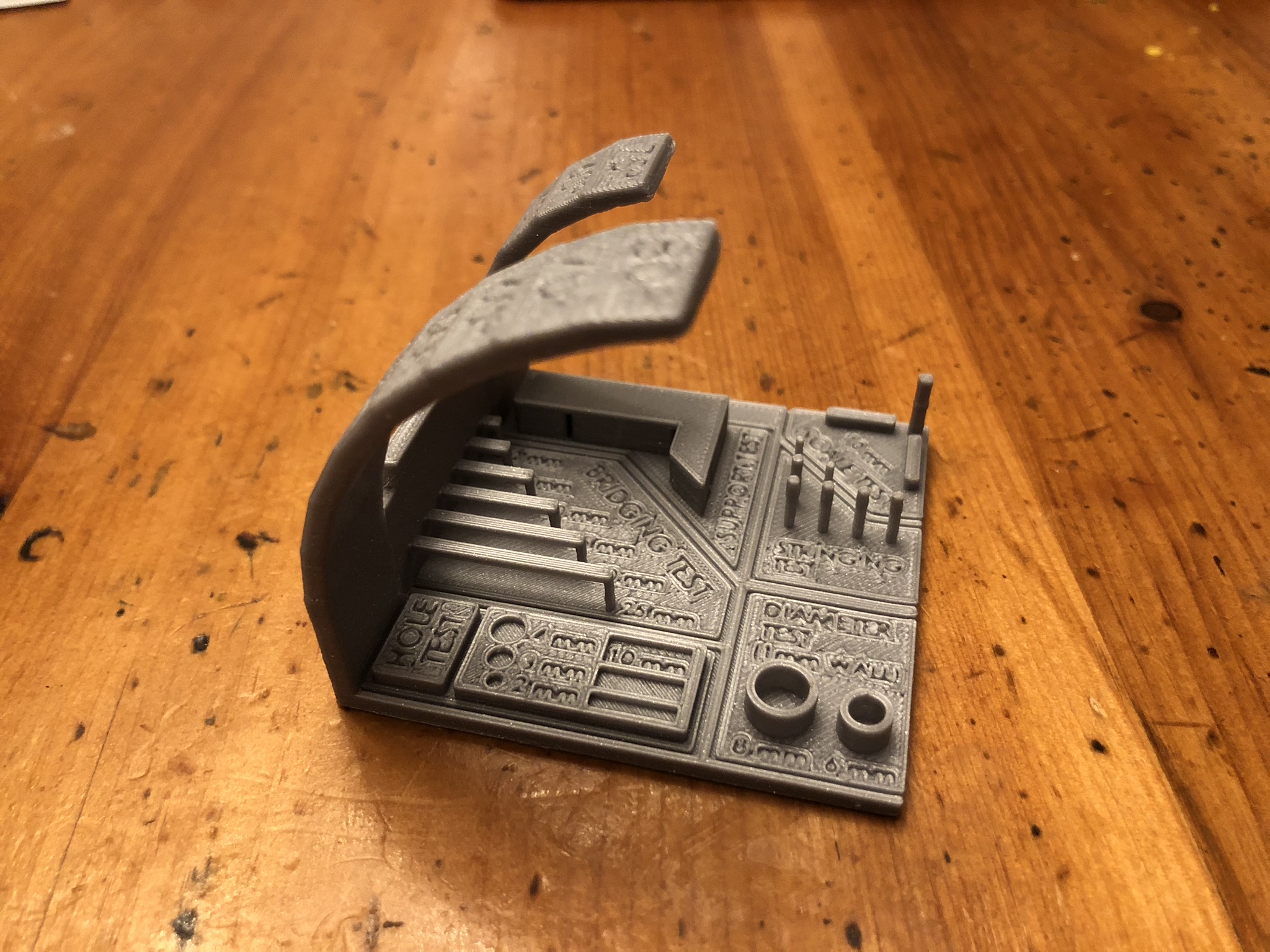

The third photo is from a print that completed "successfully" (an iris box), but the bottom is curved up on one side (not flat). There are also some more minor defects in the sides of the box.

I was first using Prusa Control, but when I realized it hadn't been updated in so long, I switched to Slic3er PE. However, my results are similar. What settings should I be tweaking to improve these printing issues? (I'm still using the silver Prusa PLA for all these prints.)

Thank you in advance!!

Re: Prusa demos print great, but things I slice... not so much

What slicer and settings are you using? The options vary considerably between slicers.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Prusa demos print great, but things I slice... not so much

I'm currently using Sli3er Prusa Edition with the default settings for the MK3 and Prusa PLA. But I don't know enough to identify if this is a z-level (first layer) issue, an extrusion multiplier issue, a retraction issue, a hotend temperature issue, etc.

I'm new to the 3D printer world, so I have a lot to learn. 🙂

Re: Prusa demos print great, but things I slice... not so much

Looking at your 1st pic, it does look like you may have some 1st layer adhesion issues. The warped iris box also indicates adhesion issues, as PLA is usually fine at that size. You could turn on brims just to get a result, but you want to nail the 1st layer.

I'm currently using Sli3er Prusa Edition with the default settings for the MK3 and Prusa PLA. But I don't know enough to identify if this is a z-level (first layer) issue, an extrusion multiplier issue, a retraction issue, a hotend temperature issue, etc.

There are 2 possible issues:

Make sure you've got that 1st layer going well before trying anything more complex.

It is odd that the Prusa gcode prints were fine, though that could simply be a coincidence coupled with your having handled the bed in between. The good news is that all the hard parts seem to be working, so you're very close.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Prusa demos print great, but things I slice... not so much

Looking at your 1st pic, it does look like you may have some 1st layer adhesion issues. The warped iris box also indicates adhesion issues, as PLA is usually fine at that size. You could turn on brims just to get a result, but you want to nail the 1st layer.

There are 2 possible issues:

Make sure you've got that 1st layer going well before trying anything more complex.

It is odd that the Prusa gcode prints were fine, though that could simply be a coincidence coupled with your having handled the bed in between. The good news is that all the hard parts seem to be working, so you're very close.

Thank you so much for the information! I have been cleaning with 91% IPA, but not every time. I should also clarify that the iris box was printed at 140% if that makes a difference.

I was playing with the gcode in the "life adjust z my way" thread last night. (The temperature settings in the gcode are very different from the Prusa defaults, which puzzles me.) I'm having trouble determining what is the "best" result. What exactly am I looking for? I can get a continuous square at multiple different heights. I have to change the z-value by at least a tenth of a millimeter before I see an obvious difference. If the surface of the square feels rough (like coarse sandpaper), should I raise or lower the nozzle? How sensitive is the z-value? Is there really a difference between -0.905 and -0.917, for example?

Re: Prusa demos print great, but things I slice... not so much

You don't necessarily need to use an IPA wipe every print, but definitely after you've contaminated the sheet with your fingers or other body parts. I can often get away with wiping once a day if I'm careful with handling prints on removal. If unsure, give it a wipe.

[...] I have been cleaning with 91% IPA, but not every time.

I should also clarify that the iris box was printed at 140% if that makes a difference.

If anything, I'd expect a larger print to adhere better.

I was playing with the gcode in the "life adjust z my way" thread last night. (The temperature settings in the gcode are very different from the Prusa defaults, which puzzles me.)

The provided gcode files just give a "known-good" start for "average" PLA. They're not necessarily ideal, but should work. At some point, you may want to create your own equivalent files for your chosen materials, nozzle sizes etc. Those will get you going.

I'm having trouble determining what is the "best" result. What exactly am I looking for? I can get a continuous square at multiple different heights.

It's a bit of a goldilocks thing.

The ideal is when it's low enough that you can drag a finger over a line without it peeling away. Adhesion is the key. Look at the underside of the sample Prusa logo your printer shipped with for an example.

I have to change the z-value by at least a tenth of a millimeter before I see an obvious difference. If the surface of the square feels rough (like coarse sandpaper), should I raise or lower the nozzle? How sensitive is the z-value? Is there really a difference between -0.905 and -0.917, for example?

My starting mistake was being too timid and just living with it until I mistakenly blew away my setting. That was a good thing, as I started from zero and got it right. Starting out, you'll have to make BIG adjustments, but as you get close, 0.02mm seems be to a reasonable step size. Between -0.905 and -0.917, there's likely not a lot of difference, but you're hoping for a happy medium that will work with a variety of materials and filament brands. A tiny bit close (more negative) is probably better than a tiny bit higher.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Prusa demos print great, but things I slice... not so much

I just wanted to follow up with the results of my experiments. I spent quite a bit of time dialing in my z-height. My prints are looking better, but there seems to be a reasonable range where it prints well. (Which I think is actually a good thing, since if the z-height was so sensitive that you had to be within a thousandth of a millimeter, printing would be much more difficult.)

I have been cleaning the bed with 91% IPA, but I was still seeing inconsistent results. A calibration test print would be perfect, and then if I tried to repeat it, it would fail. And the failures weren't always in the same spot. However, yesterday I was finally able to successfully print the Pangolin model that was giving me so much trouble.

But tonight, I printed a calibration test and it looked okay. Then, I tried to print a small model (an extrusion visualizer) and it failed by not sticking to the bed properly. And then I had an idea: I flipped by spring steel sheet over to the side I've not yet used. Without changing any settings, the same model printed flawlessly. I've been printing all evening, and everything is adhering to the bed very well.

My conclusion is that I likely need to use some acetone to rejuvenate the original side of my spring steel sheet. The fresh/unused surface is working so much better. Since I printed several of the Prusa demo models first, they were all done on the new surface. As I've been progressing into other models, the print surface probably just needed a refresh.

Thanks again for your help and advice!

Re: Prusa demos print great, but things I slice... not so much

You mention using 91% IPA. Keep in mind that if that is a bottle you have had around for a while, it is going to be lower than 91% because it absorbs water from the atmosphere. If you leave the cap off for a while or loose, etc.

I've had my MK3 for just under a week and pretty much running it constantly. I'm cleaning the PEI spring steel sheet with generic "Windex" after every print (PLA) and once a day with 100% DNA (denatured alcohol) from the hardware store (sometimes sold as camping stove fuel). Only sticking issue I've had was my own fault for not adding a brim and some supports to a print. I call it 100% DNA but of course, same problem with absorbing water from atmosphere. But at least this is a metal can with a gasketted lid.

This DNA (denatured alcohol) is a 50/50 mix of ethanol and methanol. Same stuff I use for other purposes including mixing and diluting shellac. Methanol is a bit more aggressive solvent and also not so great for prolonged skin contact. So if you use something with methanol keep in mind to minimize your contact with it.