RE: Problems with PETG first layer

Good to know.

RE: Problems with PETG first layer

Dear all,

Could you please specify what steel sheet (textured or smooth) are you using?

I have both and with the textured one, I have no problems with PETG, just prusaslic3r defaults for PETG and everything runs fine.

With the smooth sheet I cannot get the first layer right. The filament sticks to the nozzle and not to the steel sheet.

MK3 updated to MK3S / mainly textured steel sheet (also have a smooth one) / PLA and PETG

RE: Problems with PETG first layer

have you readjusted live Z with the smooth sheet?

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Problems with PETG first layer

@joantabb

yes... not live, but I added a new sheet profile on the printer and I made the First Layer Calibration, so I have 4 profiles:

SmooPLA, SmooPET, TextPLA, TextPET.

But I cannot get PETG to stay on the smooth steel sheet (and is basically brand new one I got from Prusa few weeks ago). Not even after IPA cleaning.

MK3 updated to MK3S / mainly textured steel sheet (also have a smooth one) / PLA and PETG

RE: Problems with PETG first layer

Good morning Jorge,

The smooth stickered sheet has a thicker layer of non conductive material (Adhesive layer plus PEI Sheet) on each side of the core spring steel, so your live Z for the sticker sheet should be about 0.2mm higher than that for the textured powder coated steel sheet,

your normal first layer thickness is about 0.2mm so if the textured sheet live Z is set up correctly and you have simply replaced it with the stickered sheet, your nozzle will be too close to the surface of the new build plate.

With PETG, if your nozzle is too close to the model or the build plate, the molten filament tends to build up on the outside of the nozzle rather than be pushed to the side as tends to happen with PLA...

so my best guess is turn the printer on, readjust the live Z value whilst the printer is idle, so that the live Z value is say +0.4mm higher than it was for the powder coated sheet, and then re running which ever live Z setup process you prefer...

If I am correct you are dangerously close to scratching your Smooth PEI Sheet with your nozzle, which is why I suggest moving the nozzle up, before doing anything else,

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Printing mistakes with PETG

when using petg on my davinci 3D printer it always comes out with improfections. Printer: DaVinci 1.0. It will come out with little strings of filament still left on top and so on. I think it could be going around the nosels gear. If so an way to fix it. I can use all the help I can get! Thank You!

Printing mistakes with PETG

when using petg on my davinci 3D printer it always comes out with improfections. Printer: DaVinci 1.0. It will come out with little strings of filament still left on top and so on. I think it could be going around the nosels gear. If so an way to fix it. I can use all the help I can get! Thank You!

when using petg on my davinci 3D printer it always comes out with improfections. Printer: DaVinci 1.0. It will come out with little strings of filament still left on top and so on. I think it could be going around the nosels gear. If so an way to fix it. I can use all the help I can get! Thank You!

RE: Problems with PETG first layer

I think I am at my breaking point with this problem. I was printing PETG just fine with a kit versionof the MK3s on a smooth steel plate. I started having issues and in attempting to chase down the issue I ended up replacing the heartbreak, heater block, nozzle, and moved to a textured plate. I have attempted live z adjust and have gone through the whole wizard several times. I am able to print a small a small square in the center of my print bed one layer high. Its skirt and when I try to print the 3x3 calibration squares all I end up with is a gummed up hot end.... which is what got me here in the first place. My printer profiles in the Prusa's Slice is all default. To be honest it all seems like a bed leveling issue but I thought that's what the PINDA was supposed to do. Any help at all would be appreciated I am just really in the weeds at this point. (feel free to move to another/different topic if this doesn't belong here)

RE: Problems with PETG first layer

@polyfaux

What about some pictures?

At first glance it sounds like the petg is sticking to the nozzle.... An full style silicone sock could help (I think E3D call them pro style) or a copper plated nozzle (petg won't stick to it)...

But I was able to print petg just fine without those artifacts. The Z adjustment is tricky... If you squeeze it too much it will stick to the nozzle, if you don't squeeze enough it will tangle and end up in the nozzle as well.

Is the metal sheet clean? I use dish soap, hot water and the green side of a dishwashing sponge to clean it (gently), I dry it out with paper towels and then I clean with another paper towel and 99.9% IPA.

About the bed leveling... Have you tried the 7*7 bed leveling? (Instead of the default 3*3). Its available on the recent firmware versions from the menu of the printer.

MK3 updated to MK3S / mainly textured steel sheet (also have a smooth one) / PLA and PETG

RE: Problems with PETG first layer

It might be warping? What about adding a brim and, if possible, make the corners round.

MK3 updated to MK3S / mainly textured steel sheet (also have a smooth one) / PLA and PETG

RE: Problems with PETG first layer

🙁 PETG sticks to the PEI too well when you get it printing correctly. You need to use a separator such as window cleaner (Windex, Windolene in the UK,) glue stick or hair spray. My preference is window cleaner as it cleans the bed as well as providing separation.

Regards,

Martin

This

Every man I meet is in some way my superior. --Ralph Waldo Emerson

RE: Problems with PETG first layer

I haven't had any issues printing PLA to date with several different filaments including the Prusa silver. Now, I'm using a couple of different PETG filaments from Atomic. I've succeeded on 3 very small prints with PETG, but the first layers weren't the best. For instance, when I printed a bench, none of the lettering in that layer was legible. The layers after that point look fine and the print quality has been good.

I have the problem where it goes to print the perimeter. The first cm or two don't quite stick and then the rest of the perimeter line looks fine. The real problem is when it starts on the part I'm printing. The extruder is going back and forth, but the goo is just getting stuck to the outside of the nozzle and isn't staying on the bed. Glue stick seems to make it worse. I've had my few successful prints on painters tape and one on just the PEI sheet with nothing else. I've used 240/70 for first layer temperature and also tried 245/70, 240/60. What is the key to getting that to stick so it doesn't just glob onto the extruder nozzle?

I’ve never used Atomic but I seem to have settled on 255/70, 150% first layer height (and width), and about 30% first layer speed. PEI plus glue (for release). Fast retract for stringing. Normal first layer squish.

Every man I meet is in some way my superior. --Ralph Waldo Emerson

RE: Problems with PETG first layer

To me that looks too low or too much extruded filament.

Have you checked your extruder calibration?

Use pronterface, measure 11 cm exactly! along the filament from where it goes into the top of the extruder and mark it, now extrude 10 cm and you should measure 1 cm exactly from the mark to the top of the extruder, any less or more and your calibration is wrong.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Problems with PETG first layer

@chocki

I ran through several more leveling prints then decided to check the extruder per you suggestion. Now I checked before the MMU, for a 10mm extrusion it appears I am only extruding 7mm. I don’t see anywhere where I can change that on the printer. Is this only a slicer option?

RE: Problems with PETG first layer

@martin-w15

I tried your settings this week and had a great success with my first PETG print. Once it was dialed in it was like the printer was printing with PLA again. So easy!

However, I found that with the most recent FW on a 3.5s w/MMU2s upgrade, I had to remove the 0.2 Z Offset. I found that after a few first layer calibration prints, a .02 increase in magnitude of the existing PLA offset left me with great results. The first level speed and temp changes were spot on and should be considered de-facto settings for those who don't see expected results when moving up to PETG.

RE: Problems with PETG first layer

Thanks for all the recommendations on that page, I am brand new to the exciting world of 3D printing and this forum is a huge help for me. Thanks to a wider skirt, brim, lower first layer speed and high bed temp, I finally managed to print the clips for the Lack enclosure without ending up with a big goop of PETG stuck to my nozzle. I am also using a powder-coated sheet.

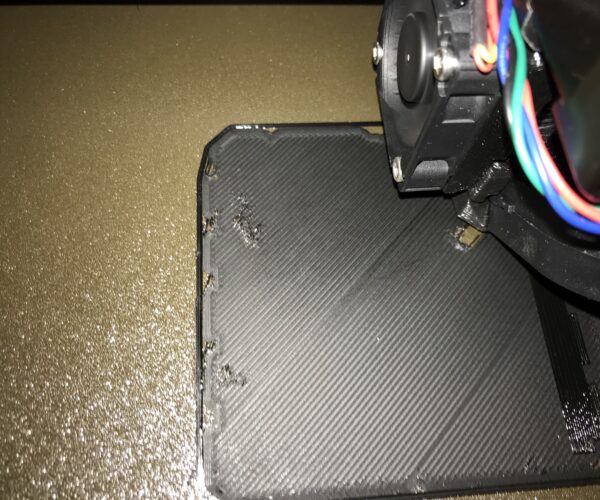

Despite all this, I still have some defects on the first layer as you can see on the picture below. Would you have any pointed as to why this is happening?

Thank you!

RE: Problems with PETG first layer

What speed are you running the first layer?

Your nozzle might be a little too close to the bed.

Do you have a photo of the underside of the part in the photo?

RE: Problems with PETG first layer

@pe-pomes

That really looks like a bed adhesion issue as the rest of the layer looks quite nice. If you can go through all the cleaning steps to get your print sheet prepared, then I'd tweak with the Z-Offset in the first layer calibration menu option. If your value is giving you good results, then try the glue stick. I've never had to use one as changing the first layer speed and bed temp with some minor Z-offset has gotten me to the place where I'm printing as expected.

RE: Problems with PETG first layer

To me that looks too low or too much extruded filament.

Have you checked your extruder calibration?

Use pronterface, measure 11 cm exactly! along the filament from where it goes into the top of the extruder and mark it, now extrude 10 cm and you should measure 1 cm exactly from the mark to the top of the extruder, any less or more and your calibration is wrong.

How would one go about adjusting this so that the cailbration is correct, if it is, and how much variance is within specs?

TIA

Drinking alcohol can cause memory loss. Or worse, memory loss!