Print issues after MK3S Upgrade

After upgrading the extruder of my Prusa MK3 to the MK3S, I started getting really unsatisfied with the quality of my prints.

Since the issues did not start immediately after upgrading, I am not sure if this is related to the upgrade or not.

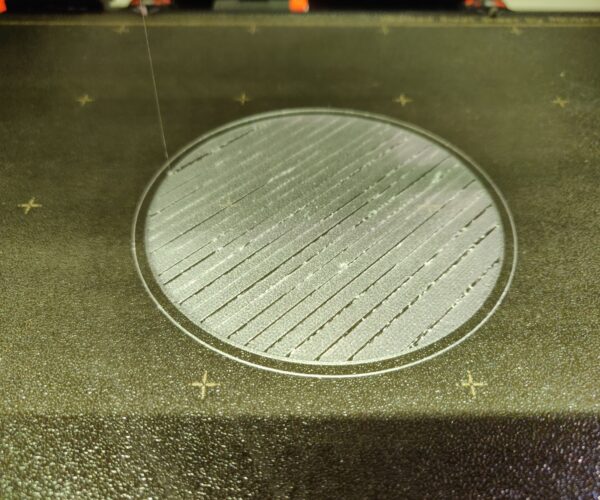

This is what the first layer of my prints usually look like:

These incomplete extrusions happen throughout the print and eventually cause issues due to filament blobs at the nozzle.

This happens with all kinds of filament (PETG, PLA, Prusament PLA). This massively degrades the stability of printed objects and is really annoying.

What I tried so far:

- First Layer Calibration

- Flow parameter adaptions (95-110)

- Tightened all screws

- reduced belt tension of X-Axis (was probably too tight after the upgrade - now it seems way too loose)

The belt calibration values (LCD-menu) have not really changed after reducing the tension of the X-Belt, though

If someone knows the reason for this poor print performance, please get in touch!

Thanks!

Best Answer by OrzelPiotr:

Check bondtech gears. dust or filament may stuck between teeths.

RE: Print issues after MK3S Upgrade

After upgrading the extruder of my Prusa MK3 to the MK3S, I started getting really unsatisfied with the quality of my prints.

Since the issues did not start immediately after upgrading, I am not sure if this is related to the upgrade or not.

This is what the first layer of my prints usually look like:

These incomplete extrusions happen throughout the print and eventually cause issues due to filament blobs at the nozzle.

This happens with all kinds of filament (PETG, PLA, Prusament PLA). This massively degrades the stability of printed objects and is really annoying.

What I tried so far:

- First Layer Calibration

- Flow parameter adaptions (95-110)

- Tightened all screws

- reduced belt tension of X-Axis (was probably too tight after the upgrade - now it seems way too loose)

The belt calibration values (LCD-menu) have not really changed after reducing the tension of the X-Belt, thoughIf someone knows the reason for this poor print performance, please get in touch!

Thanks!

Irregular extrusion, possibly caused by a blocked hotend or insufficient idler spring tension. I assume that you have cleaned the printing bed clean and free of any greases and dust.

https://help.prusa3d.com/en/article/clogged-nozzle-hotend-mk3s-mk2-5s_2008

have you upgraded the latest fw (3.9.2)?

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Print issues after MK3S Upgrade

@karl-herbert: Thanks for your answer!

This is an issue that I have for quite a while. The print bed has been cleaned several times. The hotend is clean: Whenever I change filament, the new filament color gets out right away. Firmware is up to date. This strange effect seams to have some kind of regularity.

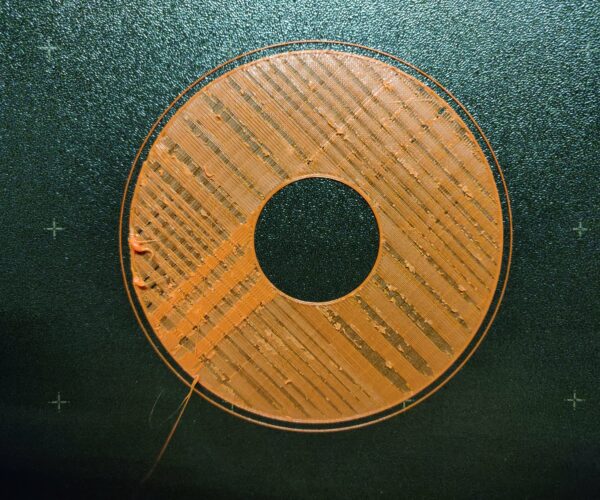

Here is another picture of the issue:

Any further idea?

RE: Print issues after MK3S Upgrade

Check bondtech gears. dust or filament may stuck between teeths.

RE: Print issues after MK3S Upgrade

@orzelpiotr

Wow. You nailed it!

Turns out that the distortion in the print happens at every revelation of the bondtech gear. I opened the idler door and found out that the little gear in the door did not turn easily. So I blew off some of the dust of the gears on both sides and put some lubrication onto the axle in the idler door.... and the odd behaviour disappeared 🙂

Thanks so much!

RE: Print issues after MK3S Upgrade

Next time you look in the idler door, check that the bearing pin for the Bondtech Idler, is partially located in both support bosses, the bearing rod is a bit short and can slip out of one side, or the other. leading to poor extrusion.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK