Priline Carbon Fiber Polycarbonate Not Good

I have been using Prusament CF PC for a while now and I love it. However, it is expensive (and out of stock), so I decided to try something else out for the hell of it. I ordered Priline CF PC filament and all I can say is, wow. This stuff is not very good. I don't know what blend % of CF (or any other additives for that matter) is in this filament, but it's not very high. It's not very rigid.

The stuff crackles and pops during extrusion (0.6mm nozzle) anywhere above 270c, but will NOT stick to the bed properly unless it's around that. Remaining layers must have to be astronomically lower in temp because this stuff is basically like printing rubber. It just warps and falls all over itself. Others have stated 235c nozzle temp works really well, but this temp will not stick to bed even with glue. Bed temps above 100c and your print will stay floppy rubbery and curl up. I don't have anything to compare this filament to, but it's definitely not a high quality PC CF blend. It's much softer than PC. I've heard quite a few people compare it to PETG. I've seen all kinds of settings recommended on Amazon reviews, but each persons settings vary quite a bit.

I'm trying one last thing. 275c nozzle, 100c bed on first layer, 235c nozzle, 90c bed all remaining layers. I'm trying my hardest to get the filament to harden up. It's NOTHING like Prusament's CF PC filament.

Has anyone had any real success with this filament? I'm about to box it up and ship it back to them.

SUCCESS! Read Below

So I had a successful print with no major first layer issues or distortion of outside perimeters as previously experienced. Basic settings are as follows:

Start with:

- 0.6mm Hardened Steel Nozzle

- Prusament PC Blend Carbon Fiber Presets @ 0.35mm resolution

Modify:

- First Layer Nozzle Temp: 270c (for best bed adhesion)

- First Layer Bed Temp: 100c (for best bed adhesion)

- First Layer Thickness: 0.2mm (for best bed adhesion on textured sheet, use glue stick)

- First Layer Speed: 15mm/sec (keeps sudden direction changes from peeling first layer up)

- Middle Layers Nozzle Temp: 235c (Prevents middle layers from distorting)

- Middle Layers Bed Temp: 90c

- Middle Layers Thickness: 0.36mm (I'll explain this below)

- Support Material Speed: 35mm (Normal 50mm/sec tends to rip first layer support material up and put it into your part print area)

Okay, so the 0.36mm thickness came from a CarbonX PC+CF recommendation via Vision Miner. While this is a different filament, they pointed something out that made sense:

"Ideal layer height is 60% of nozzle diameter. We do not recommend printing layers below 0.25mm with carbon fiber grades. Lower than 0.25mm may create too much back pressure in the hot end and result in poor feeding, jams, drive gear clicking, and eating a notch into the filament."

60% of a 0.6mm Nozzle is 0.36mm. While I thought I'd be sacrificing the overall appearance of the part by increasing the layer height by this much, but the part turned out awesome!

Let me know if you'd like some pictures and I'll post them up!

RE: Priline Carbon Fiber Polycarbonate Not Good

I'm so happy to see that you have shared this. I just removed a Priline PC prototype part from the print bed which is hard as a rock. (I had to seat it into the metal opening by hammer installation...see Pg 3 of the install instructions lol). There's some minor warping and a little sagging over a 2mm gap. Neither of these are acceptable for an automotive part that I plan on marketing to the Jeep community.

I'll try your settings and see how it comes out

RE: Priline Carbon Fiber Polycarbonate Not Good

Glad I could help. I would maybe recommend increasing the extruder temp to around 245degf min. No cooling. Print slow, around 40-50mm/s if you can afford it.

RE:

well maybe I missed something. I squeezed out my part this morning and it was a massive blob on the top.

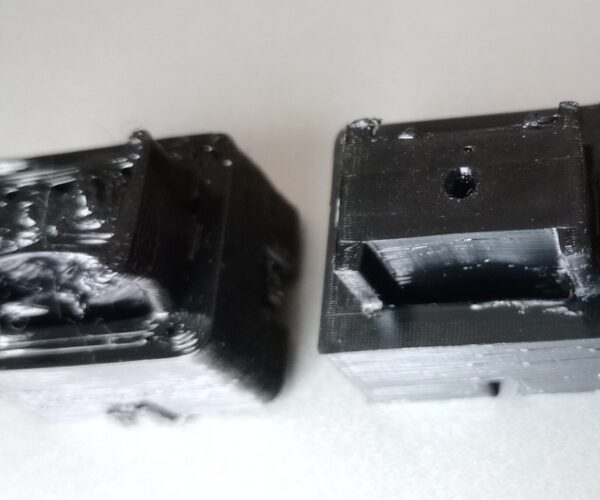

I have an elevated cros s where the sag is. I need this to be under constant stress so I increased the perimeters to make it solid. My original part was printed at .20mm and 255c which is on the right and modified on the left.

s where the sag is. I need this to be under constant stress so I increased the perimeters to make it solid. My original part was printed at .20mm and 255c which is on the right and modified on the left.

This is my enclosure still under construction. Dense foam and ceramic tile for sound absorption. Air scrubber, external mounted electronics, LED strips in 4 corners and top. A modified $21 cosori dehydrator that brought the humidity from 40 straight out of the package to 10%

RE: Priline Carbon Fiber Polycarbonate Not Good

I'm a little late the thread but could you post a picture of your results with the settings you mentioned above? Having external perimeter quality issues.

RE: Priline Carbon Fiber Polycarbonate Not Good

Middle Layers Thickness: 0.36mm (I'll explain this below)

Support Material Speed: 35mm (Normal 50mm/sec tends to rip first layer support material up and put it into your part print area)

I cannot find either of these settings. I have Expert view enable in the PRUSA Slicer app, but for the life of me, I cannot see either of these on any of the tabs (Layers, Infill, Advanced, etc)... pulling my hair out lol.

RE:

BTW - This is a Glock FMDA DD17.2 frame printed with the PRILINE Carbon Fiber Polycarbonate filament. Came out great except for something funky going on with the trigger guard. I used the above settings, except left the 0.4mm nozzle and didn't replace with 0.6mm.

RE: Priline Carbon Fiber Polycarbonate Not Good

I'll have to do some digging. I have since stopped printing with CF. It's rigidity was to its own demise. The parts made with CF are stiffer, but a lot more brittle and I had no use for it anymore.

RE: Priline Carbon Fiber Polycarbonate Not Good

Looks great. Try reprinting it with support in that area, looks like it's missing support material. I recommend downloading PrusaSlicer 2.6 and using organic supports. They work really great. Also, clogging is very common when using 0.4mm nozzles to print filled filaments and it can occur unexpectedly.

Side note: Not sure what your plans are with that lower, but I would not recommend this material for a live "firearm". I hear toughPLA is the way to go. Furthermore the print orientation can lead to dangerous layer separation from kickback. The barrel end and the grip need to be the only parts touching the bed so that the lower is at and angle.

RE: Priline Carbon Fiber Polycarbonate Not Good

Middle layers aka "Layer Height" located under Print Settings/Layers and Perimeters/Layer Height.

Support material speed is located under Print Settings/Speed/Speed for Print Moves/Support Material.

RE: Priline Carbon Fiber Polycarbonate Not Good

well maybe I missed something. I squeezed out my part this morning and it was a massive blob on the top.

I have an elevated cros

s where the sag is. I need this to be under constant stress so I increased the perimeters to make it solid. My original part was printed at .20mm and 255c which is on the right and modified on the left.

This is my enclosure still under construction. Dense foam and ceramic tile for sound absorption. Air scrubber, external mounted electronics, LED strips in 4 corners and top. A modified $21 cosori dehydrator that brought the humidity from 40 straight out of the package to 10%

It should be noted that I did all of my printing WITHOUT an enclosure, draft shield, etc. and any addition of these things will likely require change those settings i've listed.

RE:

I just did my first ever PC CF print (Priline, also my first print with Obsidian nozzle,) using the above settings. It's darn close to perfect. Thanks for posting!

MK4 Upgrdaed Y-Idler - The only thing I adjusted was the middle-layer height to 25mm to accomodate .4 nozzle and the 60% calculation described. I did use purple glue, and it was a bit hard to get off the plate, so buyer be ware.

RE:

I know this is an old post, but I found it helpful for print parameters and wanted to add a note. I spent 18 years processing PC in the optical plastics industry, injection molding of PC. Drying of the PC is a HUGE part of a successful Polycarbonate 3D print process.

Water/moisture is the enemy of PC. If water is present in PC when it is extruded, which is what you are doing while 3D printing, the moisture will attack the polymer chains, cutting the long polymer chains that make properly processed PC so tough and strong. When the moisture in the filament boils it can also cause voids and bubbles in your print. You MUST properly dry the PC before using it and keep it dry.

Crackling or popping during printing is a sure sign you have way too much moisture in the filament. Even if you do not see those indicators, a final product that is brittle or weak likely indicates too much moisture (not talking inter-layer bond which is process related, just overall properties).

You will see drying recommendations for PC filament ranging from 80C (176F) -120C (248F), for 6-12 hours. My opinion is that the 80C recommendations are made by manufacturers whose systems have max temperatures of 80C, while the 120C is a much better recommendation, here is why. Water boils at 100C. In order to remove water deep inside the material you need to convert the moisture to water vapor. This will not happen at 80C UNLESS you have a desiccated enclosure/dry system OR a vacuum oven dry system which lowers the boiling point of water. A desiccated enclosure may work at 80C. For offline drying, good vacuum systems are not cheap and most users on these forums do not have access to these systems. Vacuum systems are ideal because they reduce the boiling temp of water and suck the water vapor out, where a simple oven with no air movement will be less efficient.

My recommendations:

- Heat the PC filament to 120C (248F) for 6-12 hours. Or as close as you can get to that.

- If you have access to a or desiccated system or vacuum oven, use that for drying the spool (really should be a heated system).

- Process your PC in an enclosure, including the spools. If no desiccant dryer in enclosure setup and limited to 80C use that, but not ideal.

- If the enclosure (including spools) has a desiccant dryer integrated into it, then 80C may be fine. Shooting for a dewpoint of -30C.

- If enclosure temp can raise to 100C-110C you will keep moisture from condensing in the filament spool during print (after fully drying).

- Will need to balance enclosure temp and adequate cooling during print to maintain physical/dimensional properties. Temp/Fan Speeds/Layer Time.

To sum it up: You HAVE to properly dry the PC or you are doomed from the start. You then need to KEEP the spool dry while processing or it will begin to absorb moisture almost immediately (Shoot for less than -30C dewpoint). Crackling and popping is bad indicator, stop and dry your spool more. Brittle PC after deposition is an indicator the PC was still not dried sufficiently, change your pre-print process for these spools (and how they are stored during print).