Re: PLA doesn't stick

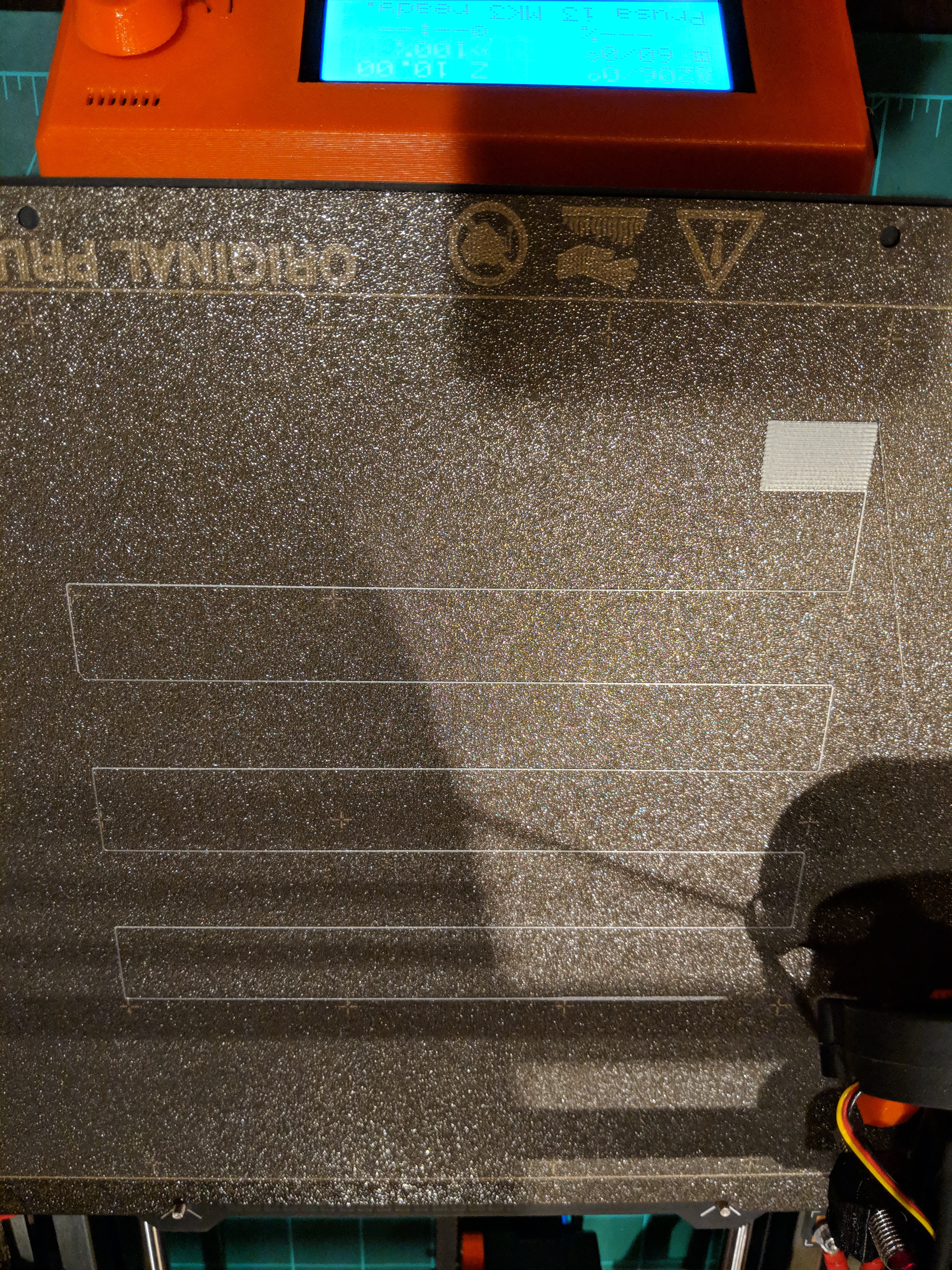

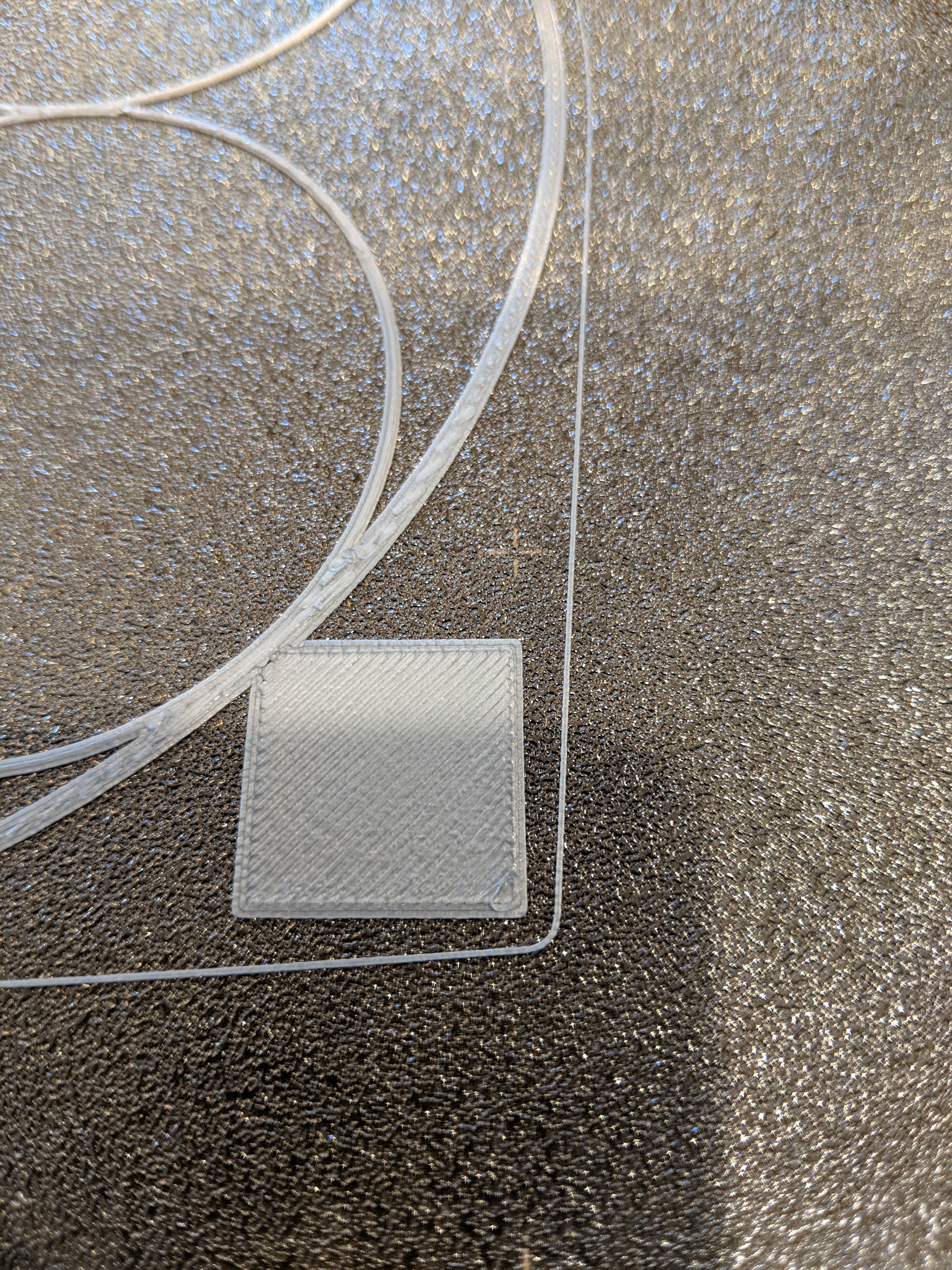

I just cleaned the bed with aceton and printed the 50 50 2 that has been posted earlier in this thread.

Lower Z some more?? To me it looks like the nozzle is already touching..??

Please have a look and give your advice.

Re: PLA doesn't stick

The waveform in the surface of your print as well as the thin area loop indicate that the Z level is a bit too low.

You are very close to the right Z level so no major adjustments are needed.

Increase Z level each time in very small increments (0.005) and make a new print.

When the surface of the first layer is completely smooth and nice, you have found the right Z level.

Bear MK3 with Bondtech extruder

Re: PLA doesn't stick

you should be able to try down 5 or 10 or up 5 or 10. easy to find out.

nice powder coated sheet.

I have a Prusa,therefore I research.

Re: PLA doesn't stick

GVT:

I have a powder coated sheet and have seen what your pictures are showing. It could be one of 2 things. Live Z too low (yes, too low) or too fast infill speed or ambient temperature issues. I have no proof to determine further yet...

I use dish soap, dawn/palmolive/etc and 90% ISO alcohol exclusively to clean, never acetone or a scrubby on a PC sheet which is different from PEI... Lee's advice for a PEI sheet may be on point, but with the PC sheet scrubbing and sanding is not necessary.

It looks well stuck to the bed. I would say Live z too low given the ridges. The ridges can cause upper layers of a print to fail as is shown in your first pic if it carries up and filament gloms onto the nozzle.

The ridges and bumps are from either too fast infill (stock settings are on the fast side) or Live z too low or ambient temp issues. In fact, I started a print earlier today and had the exact same thing you are showing in my first layers on your third pic. I just let the print continue and slowed the speed to 95% and it is printing as we speak. (tune/speed/95% from 100%). It is very cold here from the last few days and I did not change anything big so it must be temps... and I have an enclosure and have not changed anything from a previously solid first layer tests....

As long as the bumps and ridges in the first few layers are not big enough to dislodge the item and ruin the print, they will work out as the print progresses. ( I wish I took a picture when it was happening earlier today). bumps and ridges happen when either the live z is too low and the "squish" of the filament gets pushed up to the sides of that filament layer or the infill is too fast. As long as the print sticks to the bed, you will be OK, but reducing the live z to get a smooth flat layer is what prevents that.

See the Life Adjust z thread and other references regarding the ridges occurring in an otherwise stable print. I will post pictures of the completed items to show that it will work out in about 5 hours when it finishes...

_____________________________________________________________________________________

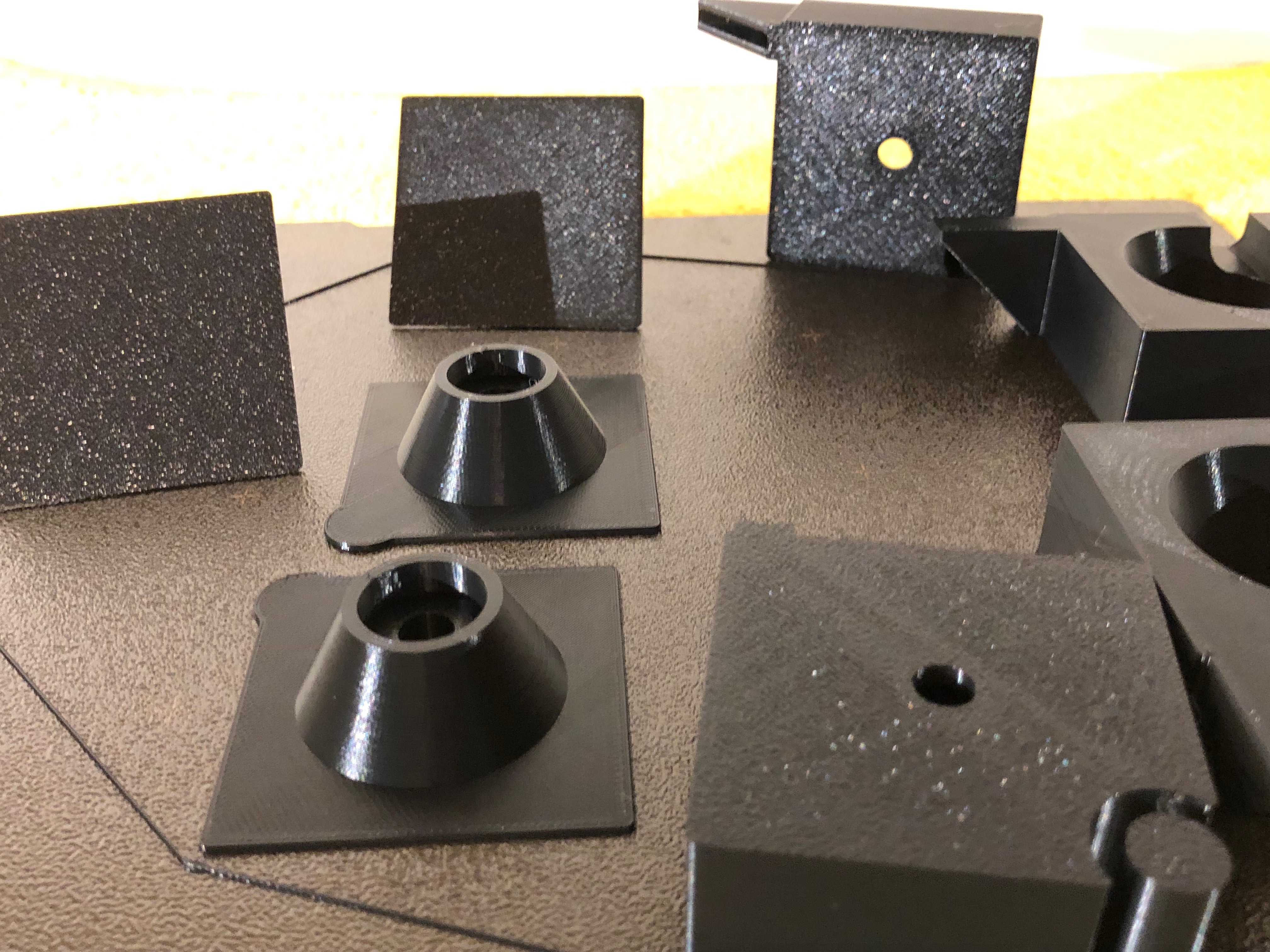

Edited to add pics. In process, completed, and completed backside. Hatchbox PLA. These had first couple of layers like your third pic. Slowed speed to 95% and let the print complete and this is how they came out.

Strange women, laying in ponds, distributing swords, is hardly a basis for a system of governance!

Re: PLA doesn't stick

Page 15 of the 3D printing handbook that ships with the Prusa i3 MK3 alludes to the process of using the "hard side of a dry kitchen sponge" in a circular motion, which is basically the same thing as I'm suggesting; it's where I got the idea. I'm sorry that you think it's silly advice but I'm speaking form a lot of experience printing PLA in a production environment. If anyone is tempted to follow my advice but is worried about the possibility of "ruining" the PEI sheet for use with other materials like ABS or PET, well you can always flip it over and use the other side for things that might be stickier. I've printed some ABS parts on the sanded side of my PEI sheet and they popped off just fine. No I won't make a video of it for your amusement, but I do appreciate that you're trying to help people, even if you're being a bit of a jerk about it.

-lee

Do NOT ruin the PEI sheet by sanding; silly advice that will ruin the sheet. Further, if you ever intend to print PET or ABS ... well, make a video of your attempts to remove the part - I'll pay to watch it. It will be hilarious.

PLA sticks to the PEI sheet as well as good masking tape; better when warm. I have to chip PLA parts off my PEI sheet.

People sanding their beds just haven't figured out how to clean the bed correctly -- or in some extreme cases MAYBE got a bad bed. A few who have done the sanding, when they figured out cleaning is needed, tried again on a CLEAN unsanded bed (their flip side was left more or less unscathed) found PLA to securely adhere to the PEI and prints came out fine.

Re: PLA doesn't stick

I just recalibrated Z using the 50 50 2 file.

I tried -1.000, -.900, -.850 and -.800

The -1.000 looked like above. Too low Z.

-0.900 looked perfect to me. But I tried -0.800.

With -0.800 I can see light coming through when holding it against the window.

-0.850 was better. But not perfect. Still some minor light through.

So I settled at -0.900.

Now I try printed some parts with standard settings: 215 nozzle and 55 bed

Btw, I don't have an enclosure yet.

@JBINFL : which nozzle and bed temperatures do you use.

Re: PLA doesn't stick

👿 👿 👿

Ggrrrrr.

The parts still come off the PC bed.

See pictures.

The longer thinner part also warps at the ends.

The second picture has the part turned to have a better view of the warping

The powder coated texture is still very visable!

What should I do???

Re: PLA doesn't stick

And another failure 😥 😥

Now used a bed temperature of 60 degrees.

I cleaned with water, I cleaned with alcohol and I cleaned with aceton. I don't see any improvement.

Prusa support, please help

Re: PLA doesn't stick

Layer 1 is still not squished enough. Each strand of extrusion should be firmly welded to the adjacent extrusion - no gaps.

Warping is due to bed temp not being hot enough. Increase bed temps 5 then 10 degrees. If you have an IR thermometer, it should read 60 to 70c.

Also - small parts warping like that is also a sign of a bed that still isn't as clean as you think. I've had 8" square parts pull up, but the PEI came up with the PLA.

Re: PLA doesn't stick

I took the 50x50x.2 test prints and tried to tear them apart by pulling sideways.

The -0.800 tears easily: not all strands are welded together

The -0.850 already needs more force. Only tears were strands are not welded together.

I can't tear the -0.900 print. I tried at multiple positions.

-0.900 was also the used settings of the last prints I posted above.

So I think the first layer is okay

I will try cleaning again. But I already used hot flowing water and the above detergents.

BTW this is the powder coated bed, not the PEI version

Layer 1 is still not squished enough. Each strand of extrusion should be firmly welded to the adjacent extrusion - no gaps.

Also - small parts warping like that is also a sign of a bed that still isn't as clean as you think

Re: PLA doesn't stick

you might be able to scale the Z by 200% and make the 50/50/.2 into a 50/50/.4 print to do a 2nd layer

I have a Prusa,therefore I research.

Re: PLA doesn't stick

[quote=gvt post_id=119060 time=1544117 just recalibrated Z using the 50 50 2 file.

I tried -1.000, -.900, -.850 and -.800

@JBINFL : which nozzle and bed temperatures do you use.

[/quote]

GVT:

I use a .40 nozzle, brass on these. I bought a fun pack and also have used .15, .60 and a hardened steel nozzle in .40. All the same things with the prints irregardless of the nozzle. My temps are 215/60 or 210/55 for PLA and 235/85 for PETG.

The jumps you made in calibration settings are HUGE! do less, much less... my adjustment each turn of the knob click is between .02 and .03, (e.g using <0.670> for example then then next rotation of the knob 1 click is to to <0.667> then to <0.665>... etc. You went 100, 50, and 50 that is like 40 or 20 click turns of the knob. use bracketing. If <0.900> looked good, try <0.875> (10 total click turns) by dialing and feeling the clicks of the turn of the knob and see what that looks like that. Then, dial from there up or down in smaller increments. 4 click turns of the knob move my adjustment in 10ths (0.670 to 0.660). I hope your knob lets you feel the clicks of each minor rotation if not, it should....

Also, I noted that if the first layer cal is off by being too low, and I adjust it, I generally let it finish and run another one at the new settings because sometimes it the adjustment does not show after it is made on the same print (if your z is too low and you are getting waves/ripples, it does not clear up fully on that print and another must be done to accurately see a good picture of the adjustment). It is tedious but works.

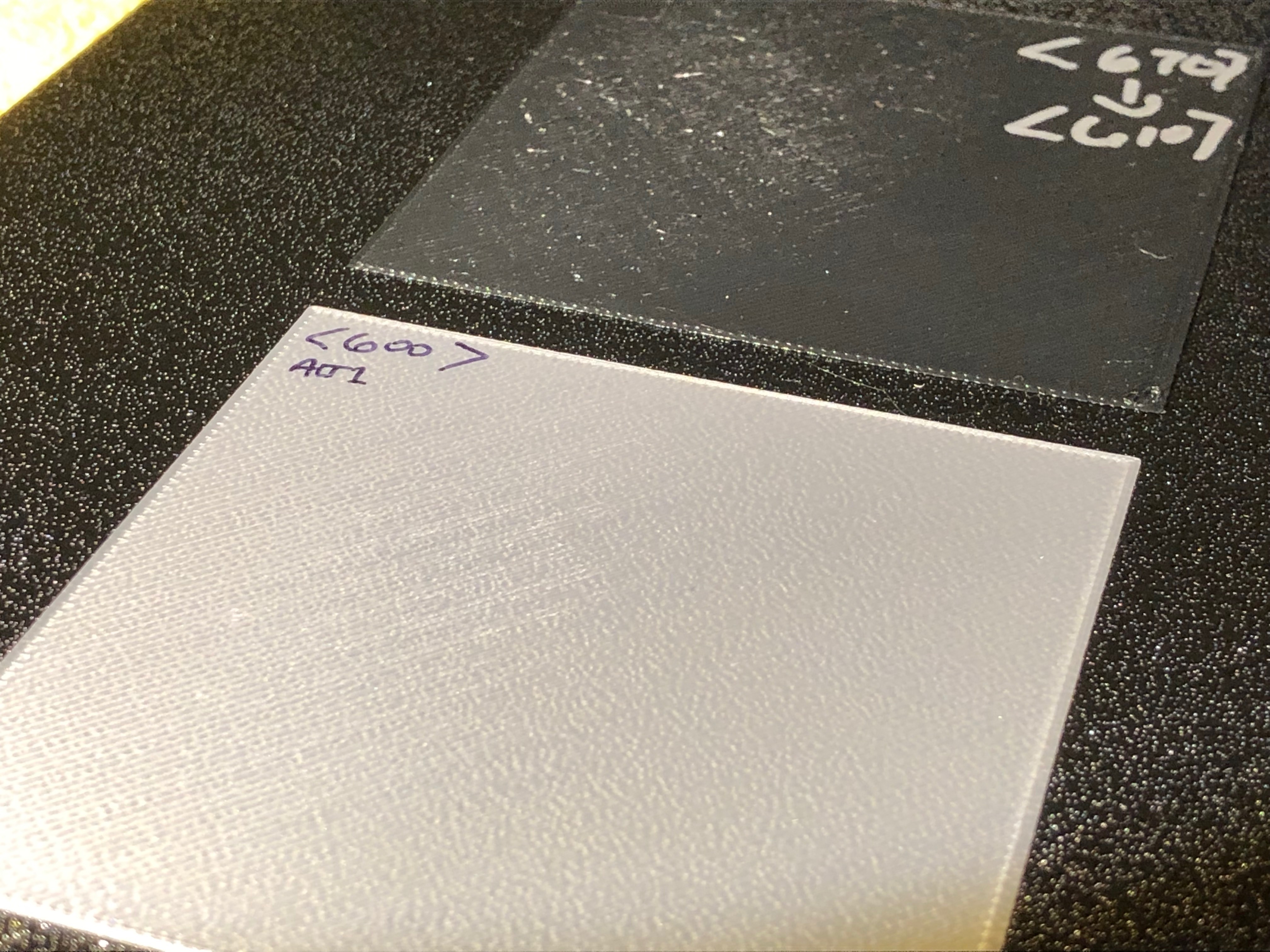

Here is an example I did with an aftermarket PC sheet. My Prusa PC sheet is good at <0.670>. the second sheet requires <0.600>. the first cal square (black) shows my adjustments from <0.670> to <0.610>. still had ripples, but clearing. Second square shows all at <0.600> and much less rippling. The black square is after a test from 670 - 650 which rippled badly all through (not pictured)...

Strange women, laying in ponds, distributing swords, is hardly a basis for a system of governance!

Re: PLA doesn't stick

From Prusa: "Double-sided Textured PEI Powder-coated Spring Steel Sheet "

The power coated is also Polyethylene ... and cleaning will be more difficult because of the divots.

Have you watched the filament extruding and seen any sign of the filament expanding after it leaves the nozzle? One of the photos shows signs of this happening ... but watching the filament is the only way to actually know. If you see the filament growing after it extrudes the filament is contaminated: either with moisture, or with something else.

I had a spool of Beige from Prusa where the entire first layer on the spool was bad. My theory was someone packing the spool had just applied hand cream or the plastic envelope it was in had an antistat coating that liked the PLA more than the bag.

And sanding a textured sheet makes zero sense.

Seriously, PLA sticks really well to PEI sheets when the PLA is good and the sheet is clean. Sure, there are cases where it gets harder to keep a part on the bed, think of printing a 8" ballerina with only toes in contact with the bed. The trick to a clean sheet is handling it by the edges as you wash it; not using too much detergent; drying with paper towels, then rinsing again with alcohol. I use two alcohol rinse steps. First with a fairly wet paper towel scrubbing the bed; I let it dry then go a second time with a damp new paper towel, wiping top to bottom.

Once I got the bed clean, PLA breaking off the bed isn't an issue. Frustrating as heck when it wasn't sticking and every dang part was coming loose. So I've been there. But it was a dirty bed (and in one case bad filament). But palm prints and finger prints are your worst enemy for PLA. The weirdest part of all this is you kinda need a dirty bed for PET and ABS... So I have two beds now. One kept sparkling clean for PLA, one for PET and ABS.

Try washing the bed again, here's my process that works fairly well, that others have tried and have found it works for them, too.

With a textured PEI sheet I'd use a new kitchen sponge: rinsed well with a drop of detergent and rinsed well.

With a standard PEI sheet I use a paper towel.

Wash hands in hot water with detergent. Dry them. <-- experience shows this is an important step.

Wash the bed with the sponge or new paper towel - a drop or two of detergent on the bed - scrub well. Try to handle the bed only by the edges.

Rinse the bed and dry with a fresh paper towel. Handle the bed by the edges.

Place the bed on the printer: favorite side up. Handle the bed by the edges.

Pour some 91% alcohol on the bed making a puddle about 3 inches diameter.

With a 1/2 a fresh paper towel, scrub the bed working the alcohol everywhere. As the alcohol starts to evaporate, use a dry paper towel to wipe the bed top to bottom. At this point you are removing mostly water.

Now - with 1/4 a fresh paper towel, hold it to the alcohol bottle and get the towel damp enough it leaves a thin stroke as you wipe the bed that evaporates fast. Wipe the bed top to bottom looking for any signs of streaks that remain AFTER the alcohol has evaporated. If you see any darker streaks, there is still oil on the bed and you aren't done. Start at step 1...

It takes me a couple minutes to wash the bed this way. Again - a dirty bed has ruined many of my print attempts. Today, if I even think I've touched the bed, out comes the alcohol or Windex if alcohol isn't pulling the print up -- then alcohol to clean the Windex residue. And I use a plastic spudger to remove most parts, or lift the front of the bed and spring it by the edges to pop parts off.

Re: PLA doesn't stick

Similar/same issue: New i3Mk3 kit with the powder coated spring steel surface sheet. Built the kit, first 2 days awesome prints, with the included Prusa PLA. Everything worked as hoped for. Running batches of the same print (need 70 items - printed 48 so far, now, can't finish even a single one on it's own.) Then it all started to fail, and now very hard to get a print to complete, and it has to be a short one.

Have washed the surface, wiped with IPA 91%, first layer z tests are always good, and hold... but when printing...after about 30 minutes, edges start to lift and then print is lost.

Some here are saying to lower the temp. Another suggests raising bed temp to 80! Have been running with the Prusa Slic3r default of 215C for extrusion, and 60C for bed temp. Most frustrating is that the same print worked great first couple days... now cannot complete.

In there, too, as a delightful complication, was a Slic3r upgrade and printer firmware upgrade....

I wonder if it is from the nylon absorbing moisture.. but has been stable 35% humidity here, don't know how much that is or is not an issue.

Frustrated. Suggestions welcome.

Re: PLA doesn't stick

Ditto!!!!

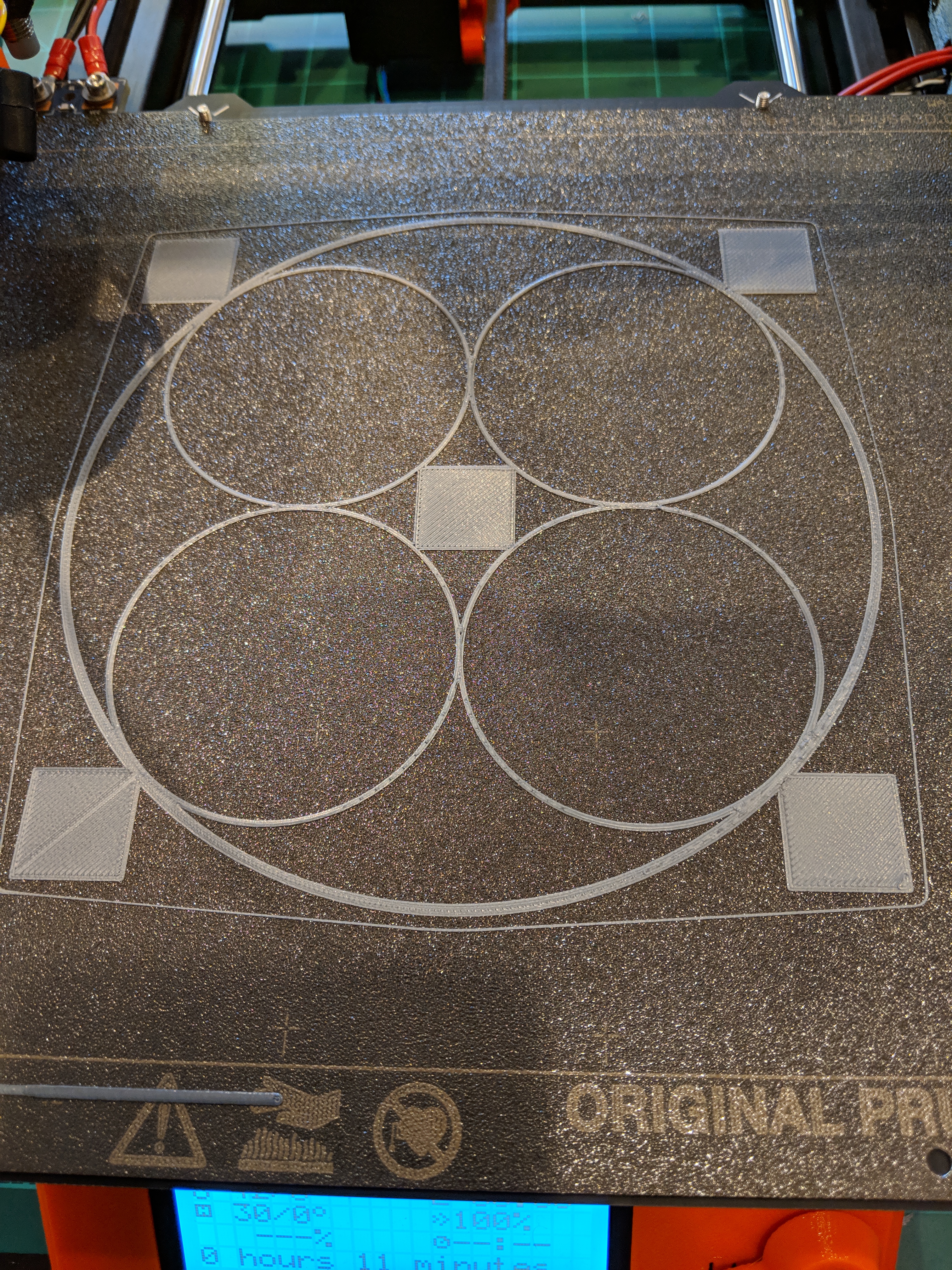

Similar/same issue: New i3Mk3 kit with the powder coated spring steel surface sheet. Ran multiple First Layer Configuration prints. I can use my finger and brush across the bed surface and not remove the filiment from the bed. If I use my nail, only a little force is needed but seems right. I've printed out another First Layer test print from Thingiverse and it seem to stick well (see pic)

I'm getting only about 20% or less of my PLA prints to stick. All others remove from the bed after 10min to 2hours into the print. Using all the standard settings from Prusa for PLA. This is happening with both the Prusa supplied gcode on the SD card and also using both Prusa Control and Sli3r PE and trying out 0.15 layer - 0.20 layer. Since PLA is suppose to be the easiest to print, like the OP, I would like to get this working without the help of glue, hairspray, software tricks.

I've made sure that I clean the bed several times like people suggested and I use 99% IPA. The PLA I'm using is what was shipped with the printer.

All software and firmware at latest release levels.

Printing in my house at 68F and 35%humidity

Ditto!!!! Frustrated. Suggestions welcome.

Re: PLA doesn't stick

Scott.m38 & William.I21:

Some thoughts... Tim.M30's advice is good for bed cleaning. Generally, prints not sticking are two main sources. Bed cleanliness and live Z levels. The advice in this thread has good info for cleaning the bed. Remember the PC sheet and PEI are different (despite both having PEI). I have never seen it suggested that I can recall, nor have I cleaned a PC sheet with Acetone or a scrubby sponge, but it might work. Someone else may have more definitive info on that ... So keep what bed material you have in mind when reading advice.

Drafts from a fan or window can effect the print sticking too. As well as humidity of the filament. nylon is super hygroscopic! then PETG, then PLA, but given high enough humidity they will all absorb moisture and it is cumulative. e.g you have to dry the filament to get the humidity out, dessicant beads don't remove moisture, but inhibit more being absorbed. I do have a LACK enclosure and it helps to shield the print from various drafts, but when it is very warm, I crack the doors open.

I would offer that if you think your test prints are good, but prints are not sticking, it could be you need more live z adjustment. The first 4 pages of the life z thread have invaluable information for this and I suggest reading it.

William.I21. I think your live Z may still be a bit too high. Compare your pictures 2&3 to my calibration square pics on this page. It looks to me like the center and upper right squares are still experiencing gaps and lines and if you pick them off the bed, they may stick together, but i bet you can feel stringiness and break apart the strands (while the print may stay together). This means the live z is still too high. Also the circles appear to have thickness to them which if it is a first layer indicates the filament is not squished enough. My first layer and perimeter lines are very squished to the bed. They remove fine when the sheet is cooled, but after printing they look much more flat than the pictures in this thread.

With a PC sheet, you can get away with more squished filaments, because as long as you let it cool, the print will pop off the sheet on its own with no risk of taking a chunk of the PEI sheet with it. I therefore tend to err to the side of being over squished than not squished enough.

I hope that helps!

Strange women, laying in ponds, distributing swords, is hardly a basis for a system of governance!

Re: PLA doesn't stick

I am realy thinking about buying a PEI sheet and test how that works.

Re: PLA doesn't stick

I am realy thinking about buying a PEI sheet and test how that works.

I went from a "theeeekkking" to the pei sheet, and after getting used to cleaning it with dish soap I have to say, it's nice.

I have a Prusa,therefore I research.

Re: PLA doesn't stick

I cleaned the bed very very well today.

1. Degreaser + nail brush -> Hot water + soap -> Hot water

2. Aceton + nail brush -> Hot water + soap -> Hot water

3. Hot water with soap

4. Alcohol

Then tried two prints again. Same problem. Both came loose 😮 😯 😕 😥 👿

What I don't understand is that the second print that I did today was a 20x20x20 calibration cubic.

I printed the same cubic just after installation of the printer and it worked well. Now it just comes loose.

I ordered the PEI sheet. Let's hope that will work.

Re: PLA doesn't stick

I am using Prusa PLA ordered together with the printer

I will try to watch the filament and make a short video

Have you watched the filament extruding and seen any sign of the filament expanding after it leaves the nozzle? One of the photos shows signs of this happening ... but watching the filament is the only way to actually know. If you see the filament growing after it extrudes the filament is contaminated: either with moisture, or with something else.