New Printer, First Layer Calibration and Adhesion

Hi,

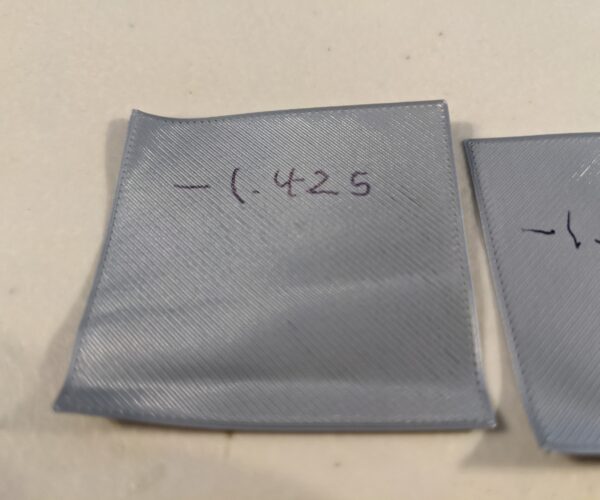

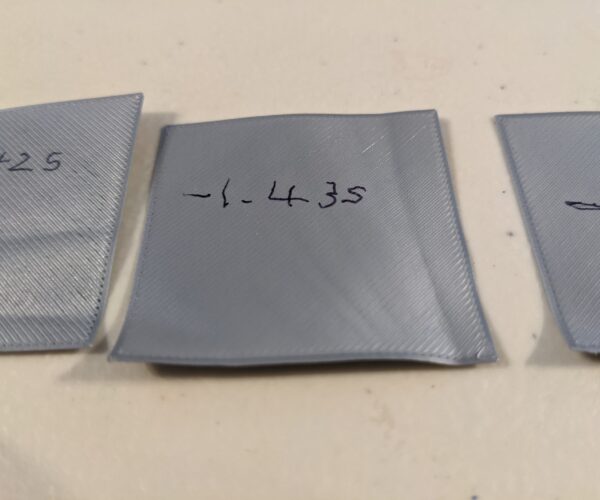

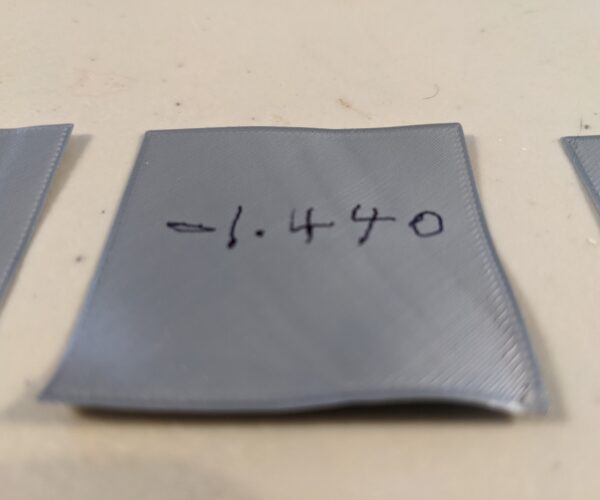

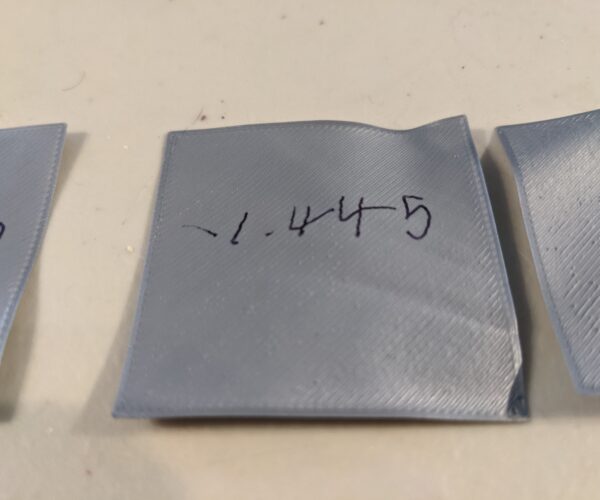

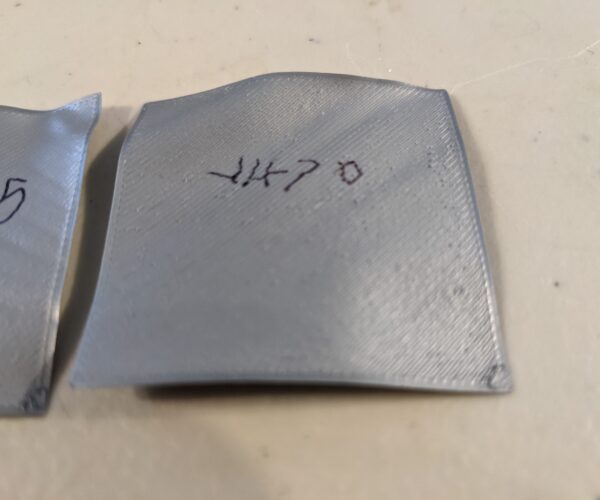

I finished assembling my Prusa i3 mk3s+ yesterday. I went through the wizard and everything passed, all axis are perpendicular. I have been having issues with my prints adhering to the print bed, so I have been spending more time trying to get the correct first layer calibration. Attached are some first layer squares I have been printing.

In the manual I read that gaps between the lines means the nozzle is too high, but ridges between the lines means the nozzle is too low. I see gaps at -1.425, -1.435 but no ridges. At -1.440 I start to feel ridges with my finger, -1.445 the the ridges are much more pronounced and -1.470 is obviously too low.

I currently have my printer set to -1.438 since it's between the square where I could see gaps and the first square where I could feel the ridges with my finger.

However, my prints are not adhering to the print bed. I have scrubbed the print bed with 99% isopropyl alcohol before printing.

Is the problem with my first layer calibration, or should I look elsewhere for the problem?

Thanks,

David

RE: New Printer, First Layer Calibration and Adhesion

Hi,

I finished assembling my Prusa i3 mk3s+ yesterday. I went through the wizard and everything passed, all axis are perpendicular. I have been having issues with my prints adhering to the print bed, so I have been spending more time trying to get the correct first layer calibration. Attached are some first layer squares I have been printing.

In the manual I read that gaps between the lines means the nozzle is too high, but ridges between the lines means the nozzle is too low. I see gaps at -1.425, -1.435 but no ridges. At -1.440 I start to feel ridges with my finger, -1.445 the the ridges are much more pronounced and -1.470 is obviously too low.

I currently have my printer set to -1.438 since it's between the square where I could see gaps and the first square where I could feel the ridges with my finger.

However, my prints are not adhering to the print bed. I have scrubbed the print bed with 99% isopropyl alcohol before printing.

Is the problem with my first layer calibration, or should I look elsewhere for the problem?

Thanks,

David

Hello and welcome to the Prusaforum!

You will find numerous discussions about your problem here in the forum. A good entry e.g. here: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/

You might also consider installing this bed modification: https://forum.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles/prusa-mini-silicone-bed-leveling-mod/

I would clean the printing plate with a good degreasing detergent and rinse with plenty of hot water. Then dry with a lint-free cloth. If necessary, finish with IPA.

Finally, perform a life z-adjust.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: New Printer, First Layer Calibration and Adhesion

If your prints don't stick to the bed - clean the bed with soap and water and then only handle the edges. Finger oil is your enemy and IPA just spreads it around. Textured sheet is NOT for PLA until you are really good at first layer. If using a clean smooth sheet and the prints are not sticking, you are still too high on your live Z.

RE: New Printer, First Layer Calibration and Adhesion

Hi everyone. Thanks for the response.

I adjusted the layer height to -1.450 and washed the sheet with dish soap + hot water, and then again with alcohol. I have now had three successful prints, with just alcohol washing between prints.

David

RE: New Printer, First Layer Calibration and Adhesion

If your prints don't stick to the bed - clean the bed with soap and water and then only handle the edges. Finger oil is your enemy and IPA just spreads it around. Textured sheet is NOT for PLA until you are really good at first layer. If using a clean smooth sheet and the prints are not sticking, you are still too high on your live Z.

Hey,

What Dan said finally caused me to do some more research. I didn't know there was different textured vs smooth print sheets. I fully understand now!

Because I'm in Canada and didn't want to deal with import taxes and/or duty I ordered my printer kit from Voxel Factory. The fast shipping was also a bonus. When ordering from Voxel Factory it comes with a textured sheet, but it mentions I could email them to get a smooth sheet. I didn't do any of that because I didn't do the research on what sheet I needed, so I ended up printing PLA on a textured sheet.

I am mostly successful with printing PLA on the textured sheets now. I wash the sheet with dish soap, I put a 10mm brim on most of my prints, I lowered the z axis a little more than I think I would need to on the smooth sheet, and I raised the print bead temperature to 70 degrees. It seems to be working okay for the short term.

I placed an order for a smooth print sheet and once it arrives I hope I can do away with most of the short term fixes.

At the end of the day I'm glad I managed to successfully assemble the printer and get some good prints out of it! Thanks Prusa and thanks everyone who responded to my thread.

David

RE: New Printer, First Layer Calibration and Adhesion

@david-payne

Hi David,

One more thing to note when your smooth sheet arrives - the sheets are all different thicknesses - so you will need a live Z setting for each sheet (some people say for each side of a sheet, but that is not my experience). The printer has a feature that allows you to store different live Z values for different named sheets - you can have a half dozen different sheets with stored live Z's if you like (there are today only 3 prusa sheet types, but you can have as many sheet profiles in the printer as you like (practical limits apply). The sheet profiles are accessed from the control menu on the printer - and are not a part of the slicer.