Horizontal Circles not round

Hi there,

currently I am printing a bunch of hose adapters/angles. They all have the same inner and outer diameter and all got printed well. (About 12 pieces already)

But now I have one specific stl file which is always elliptical, therefore the hoses won't fit in. I printed it now already 4 times, always the same!

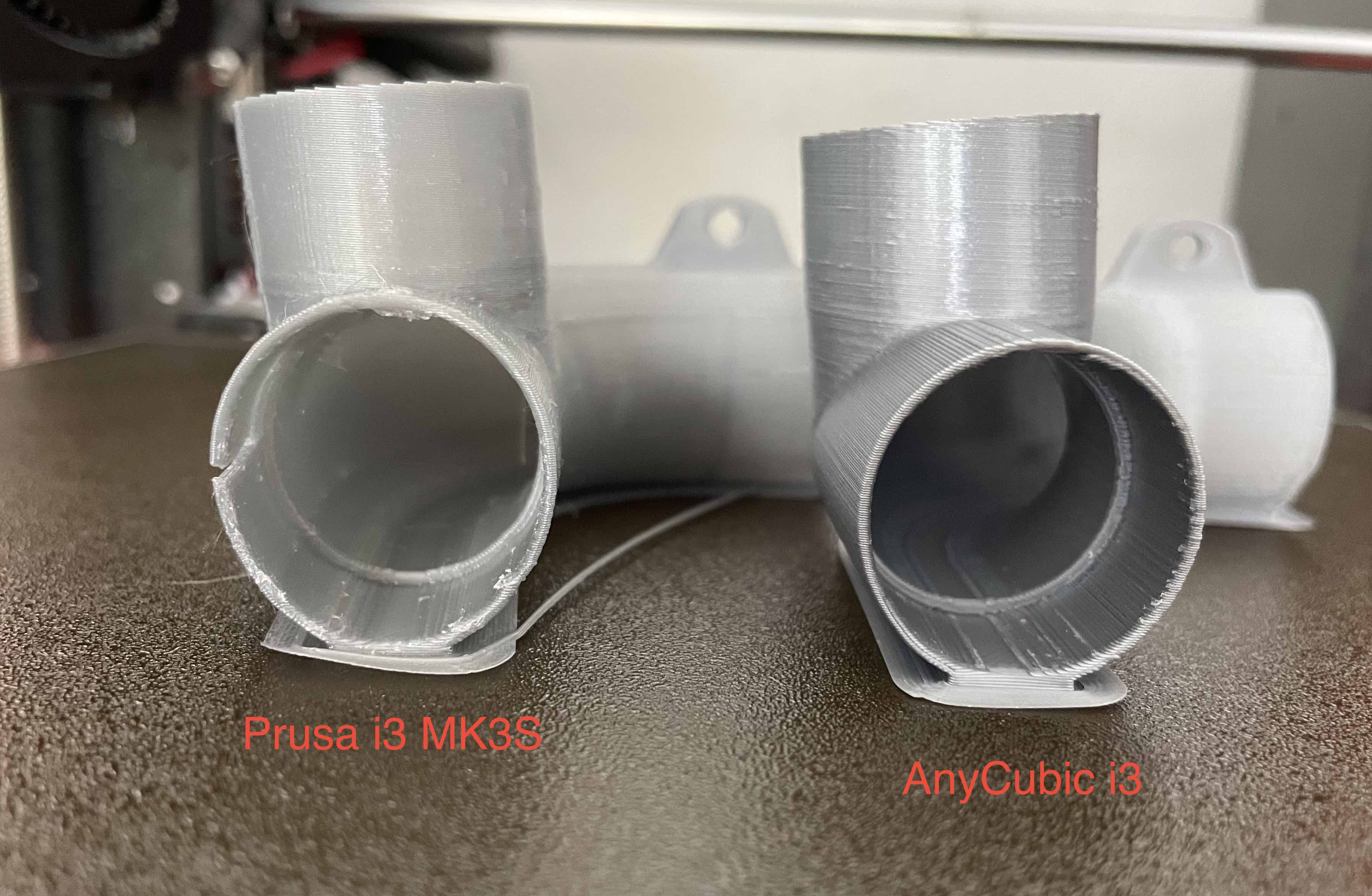

I tried already PrusaSlicer and Cura 4.9, different layer heights, always the same problem. So I thought it may be the stl file itself, so I tried printing it with my old AnyCubic but there it turns out round, the hoses fit in....

What could be the problem with my Prusa printer? Belt tension looks good, and if I print older stl files they still turn out great. So I guess it is not a hardware problem, more of software related?

On the picture left is the Prusa-print, and as you can see it broke already because I tried to push in the hose. Anycubic on the right is still good though.

RE: Horizontal Circles not round

Not round can be caused by your selection of layer height. Some models cannot be printed true to dimension if the layer heights do not add up correctly. For instance. .3mm draft, can only print true for specific hole/shape sizes ... first layer is .2mm, then add .3mm so you can get true shape at .5mm, .8mm, 1.1mm, 1.4mm, 1.7mm, 2mm, 2.3, 2.6, 2.9, 3.1, 3.4, 3.7, 4 ... and so on. If you want true take the layer height into account.

RE: Horizontal Circles not round

Post the part so we can see how you are trying to print.

How to save and upload a project

As for the notion you can't print dimensionally accurate objects using certain layer heights: if that were true 75% of my prints are then mistakes and somehow broke that 'rule.' If a part is round, it should print round, minus any layer resolution issues (think stacking bricks). In your part, one possible issue is maintaining wall thickness, then you also need to ensure good interlayer adhesion.

ps: as an aside, the orientation of the part is not helpful to make it strong - you are placing the weakest parts of the print in the most stressed areas. I wouldn't expect it to survive normal use.

RE: Horizontal Circles not round

Hi there, thank you for your answers.

I attached the project file.

Regarding layer heights, I tried printing it now wit 0.15 - 0.2 and 0.3. Same result.

Further I printed already 12 pcs with the exact same diameter, and all turned out round. Just this one file. And as I said, if I print exactly this file with another printer, it turns out round as well...

@ Tim: how would you place it on the bed then? (The print should not take to long because I need many of them :/ )

RE: Horizontal Circles not round

how would you place it on the bed then? (The print should not take to long because I need many of them :/ )

The part is inherently weaker in the horizontal plane between the layers. Usually it's posssible to rotate a part to take advantage of the greater strength along the lay of the filament. In this case there are equally vulnerable sections in X, Y and Z directions so the strongest orientation would be to rotate by 45 degrees in both X and Y, (not Z) so that at least some of the stress is vectored along the lay. This would require support.

Cheerio,

RE: Horizontal Circles not round

@tim-2

Try printing a few parts of different heights on the same bed. The printer doesn't adjust layer height to meet your dimensions. For dimensional accuracy to the .1 mm resolution, you need to print in .1mm resolution or some layers. For example, try printing a 1mm thick pinda adjuster in .3mm draft. The default .2mm first layer means you will get a part that is shorter than you expect. Try it.

RE: Horizontal Circles not round

@tim-2

Try printing a few parts of different heights on the same bed. The printer doesn't adjust layer height to meet your dimensions. For dimensional accuracy to the .1 mm resolution, you need to print in .1mm resolution or some layers. For example, try printing a 1mm thick pinda adjuster in .3mm draft. The default .2mm first layer means you will get a part that is shorter than you expect. Try it.

It isn't me having the issue - so replying to me makes no sense ... lol.

RE: Horizontal Circles not round

@patrickm

It looks like the part is designed for small FDM layers. Or perhaps even SLA style printing. Not exactly a great candidate for a Mk3 for anything except a fun and challenging print.

I'd go with a minimum 0.1 mm layers, perhaps use variable heights, and some support inside won't hurt. I suspect the non-circular issue is the fact there are unsupported perimeters collapsing.

Strength issues are what Diem has said. Aligning the part so that it can fracture along the layer boundaries is not the best way to print it - and the foot being on that axis suggests it was designed to print in that orientation - which leads me to think the part was designed for some other process.

And Dan has gone off the deep end 🙂 thinking layer one heights affect part accuracy that way. Height resolution is whatever the layer thickness is. .05, to 0.30 ... So the part can only be that accurate. It will still be round, symmetrical, etc. Just the printed height tolerance is now +/- (layer/2). If the part should be 51.55 mm, printed at 0.1 mm, it will be printed 51.50 or 51.60 mm, depending on the mood of the slicer - it might be smaller by 0.05 or larger by 0.05 mm. The layer 1 height of 0.2 mm doesn't play into this.