Good adhesion during Z-live calibration, breaks loose on build

Situation

- Built MK3S from Prusa Kit

- I'm printing Grey Prusa PLA that came with my kit

- the Live Adjust test sticks well, anything else I try to build eventually gets pulled off the bed by a growing spaghetti blob on the extruder.

- I'm in a relatively cool basement in the NE part of the US with some draft due to a furnace and I'm wondering if that is having any effect.

Steps taken

- I've enable 7x7 bed leveling

- I've washed the Texture PEI sheet with dish soap multiple times.

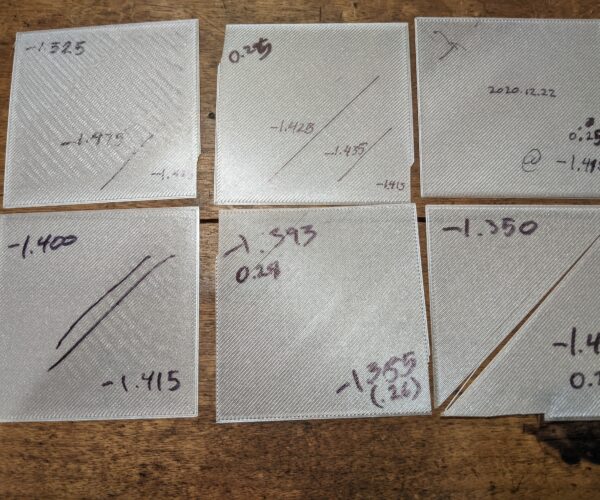

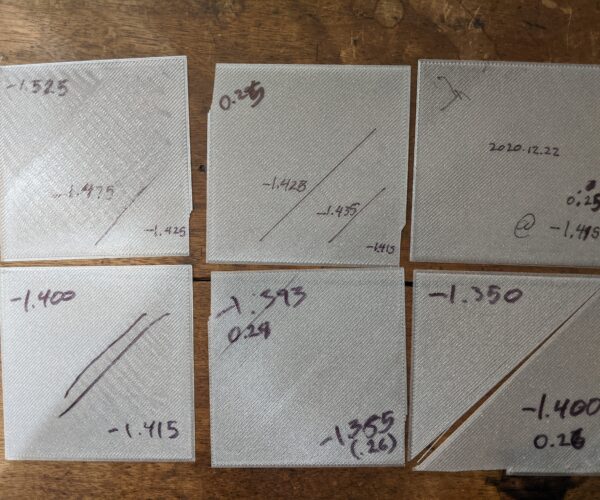

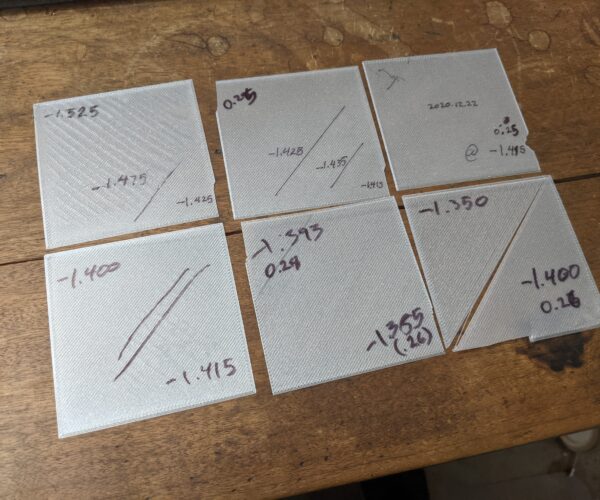

- I've tried to follow the directions from "life adjust Z - my way" to get Live Z correct. Currently -1.400, see below. Measurements in ( ) are thickness using a vernier caliper. (Micrometer is in the barn & I keep forgetting to get it)

- -1.350 is not close enough together an breaks into strands.

- -1.400 to -1.415 seems to be pretty smooth and thing (0.25mm)

- as I go down from there it gets rougher & thicker.

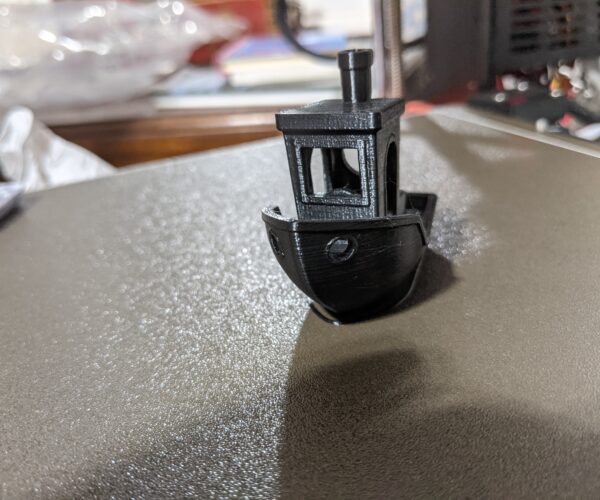

My first Benchy made it 3.5mm before breaking loose, nothing else has made it that far.

Suggestions for next steps to take?

And Merry Christmas to All, 圣诞节快乐,Maligayang Pasko

Ed

RE: Good adhesion during Z-live calibration, breaks loose on build

I prefer the built in option for adjusting the first layer and will look at the amount of "squish" in the bead laid down with a magnifying glass.

I've only used live Z a few times when I first got the printer so others will have to chime in but I have to question if live Z gets saved, I thought it only works for the current print, I thought you have to run the first layer calibration routine or save your current live Z value in the firmware with M commands if you want it to be permanent.

RE: Good adhesion during Z-live calibration, breaks loose on build

Tip: Just to get a print out of the printer I would go into the first layer calibration routine and set the nozzle a little lower than you normally would, "over squish" it a little just to get your first print to stick. If it still pops off with the first layer squished more than normal then you know you need to look at cleaning the bed more.

RE: Good adhesion during Z-live calibration, breaks loose on build

@martys

Re saving live z: according to what I've read elsewhere on this forum, If you have never run a first layer calibration, you are correct, the live z won't be saved.

I should have noted that I've already run the first layer calibration once (actually half a dozen times at least) so my live z settings are being saved in non volatile ram

RE: Good adhesion during Z-live calibration, breaks loose on build

@martys

Re saving live z: according to what I've read elsewhere on this forum, If you have never run a first layer calibration, you are correct, the live z won't be saved.

I should have noted that I've already run the first layer calibration once (actually half a dozen times at least) so my live z settings are being saved in non volatile ram

The above is correct.

The PINDA sensor though is temperature dependent. Its why many of us use customised start gcode in slicer to preheat the printer bed as well as the pinda sensor to a consistent temperature before it does the mesh leveling. I literally do not worry about the first layer anymore.

Personally if I had those live z values I would lower the probe by 0.4-0.6mm to get values around -800 to -1000 (the probe is supposed to work at up to 2mm so 1000 is bang in the middle of its range). Mine are at -854 at the moment after the last time I rebuilt the extruder and it hasnt changed in over 9 months.

Have a look at Bob's website for the details on the pinda preheat startup http://projects.ttlexceeded.com/3dprinting_mk3_pinda_warmup.html Lots of good info on Bob's site besides that too so well worth a read.

If you are getting build up on the nozzle then you may be over extruding. This is cumulative so wont be seen during the first layer calibrations. You would need to actually measure the filament diameter you were printing with, adjust the filament settings to match and then do some extrusion calibration to get that dialed in too.

Drafts could also be a problem, its one reason many use an enclosure, although they can cause their own problems, especially when printing PLA. Just setting up some dust sheets floor to ceiling to section off the printing area would probably help with that though in the basement.

RE: Good adhesion during Z-live calibration, breaks loose on build

Personally if I had those live z values I would lower the probe by 0.4-0.6mm to get values around -800 to -1000 (the probe is supposed to work at up to 2mm so 1000 is bang in the middle of its range). Mine are at -854 at the moment after the last time I rebuilt the extruder and it hasnt changed in over 9 months.

.

To reduce the offset, you need to raise the PINDA, not lower it.

You want the PINDA ~1mm above the nozzle. Easy mistake to make, but moving the right direction saves a bit of time and a bit of hair.

RE: Good adhesion during Z-live calibration, breaks loose on build

If your first layer is to low, your print can come loose(even if it looks good). I was printing pla and nothing worked, first layer was not flat om pei sheet, after going higher it suddenly worked. Do a few test with adjusting the height, and print model.

On powder coated bed, in comparison with pei sheet, you need to go a little lower, then it sticks better.

Clean bed is very important.

Preheat the printer.

Bed temperature 10 higher could help.

On youtube a saw Thomas Sanladerer saying for general 3d printer setting, make the first layer 0.3 height, and the first layer nozzle width wider, how much ? , this could help with first layer, at the moment I did not try this.

Personally I find first layer confusing sometimes, need a lot of adjusting and suddenly it works.

RE: Good adhesion during Z-live calibration, breaks loose on build

Thanks for all the imput.

Short version: Switching to Hatchbox true plack PLA worked and has printed fine.

I'll post photos later, I need to knock off I have an early drive tomorrow.

Thank you for all the advice & suggestions. I'll try to implement it to ensure I have as many things in place to prevent these kinds of issues in the future.

Ed

RE: Good adhesion during Z-live calibration, breaks loose on build

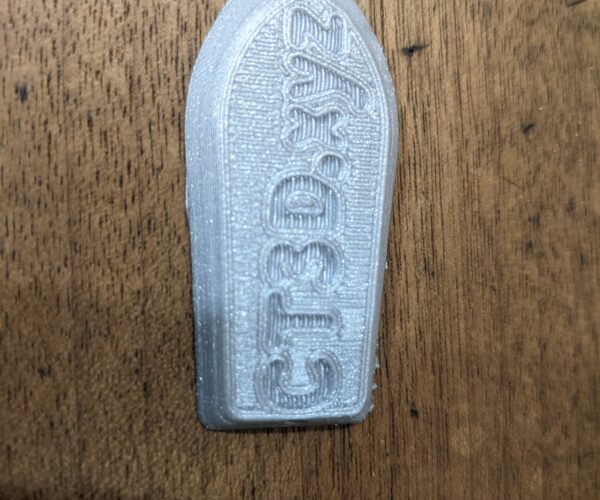

The initial Benchy print started pulling away from the bow after building up about 5-7mm. I could see the bow pulling away and the body start to rock as the extruder passed over the bow and knew that menat it was going to detach.

I washed the bed with dish soap & water and tried again

Got about 2mm before it lost adhesion.

I switched to a new batch of Hatchet Box, PLA true black. (I did not wash the bed, I wanted to change just one variable at time)

Again, I appreciate the suggestions. Very grateful for you taking time to write.

Next, I'm going to see about adding the code suggested and adjusting the PINDA to be a little closer to -1.000

Ed

RE: Good adhesion during Z-live calibration, breaks loose on build

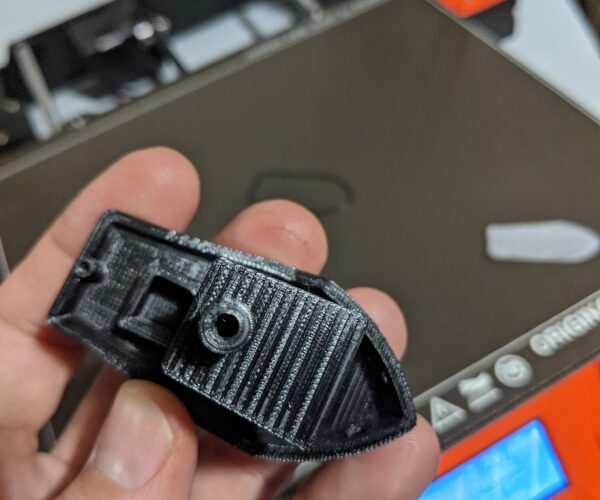

Compare your 2 pictures with the side off the print bed off the benchy, in the silver one you see very big lines(possible to high), the black looks like it is lower.

Possible the silver filament try to print hotter on the nozzle. and make bed 10 degrees hotter.

RE: Good adhesion during Z-live calibration, breaks loose on build

If I look at yout test prints, I think they are too thick.

The tickness should be 0.2 mm, measured in the middle.

The print must also be smooth on the bottom so it must not separate if you take it from the bed.

See my own solution: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/bad-adhesion-printbed/#post-339508

I would recommend to always use a brim and look at the tempetures of the nozzle and bed.

I print at 225° nozzle and 70° for the bed.