Gap Fills Issue

Hello,

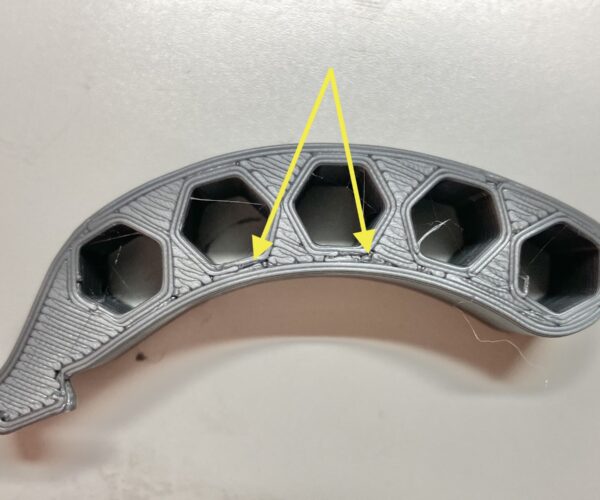

Does anyone know what settings I should change to fill those gaps?. Or at least make it look better

My settings are below.

# generated by PrusaSlicer 2.3.0+ on 2021-05-07 at 15:33:37 UTC

avoid_crossing_perimeters = 0

avoid_crossing_perimeters_max_detour = 0

bed_custom_model =

bed_custom_texture =

bed_shape = 0x0,250x0,250x210,0x210

bed_temperature = 60

before_layer_gcode = ;BEFORE_LAYER_CHANGE\nG92 E0.0\n;[layer_z]\n\n

between_objects_gcode =

bottom_fill_pattern = monotonic

bottom_solid_layers = 4

bottom_solid_min_thickness = 0.5

bridge_acceleration = 1000

bridge_angle = 0

bridge_fan_speed = 100

bridge_flow_ratio = 0.95

bridge_speed = 30

brim_width = 3

clip_multipart_objects = 1

color_change_gcode = M600

colorprint_heights =

compatible_printers_condition_cummulative = "printer_notes=~/.*PRINTER_VENDOR_PRUSA3D.*/ and printer_notes=~/.*PRINTER_MODEL_MK3.*/ and nozzle_diameter[0]==0.4";"nozzle_diameter[0]!=0.8 and ! (printer_notes=~/.*PRINTER_VENDOR_PRUSA3D.*/ and printer_notes=~/.*PRINTER_MODEL_MK(2.5|3).*/ and single_extruder_multi_material)"

complete_objects = 0

cooling = 1

cooling_tube_length = 5

cooling_tube_retraction = 91.5

default_acceleration = 1000

default_filament_profile = "Prusament PLA"

default_print_profile = 0.15mm QUALITY @MK3

deretract_speed = 0

disable_fan_first_layers = 1

dont_support_bridges = 1

draft_shield = 0

duplicate_distance = 6

elefant_foot_compensation = 0.2

end_filament_gcode = "; Filament-specific end gcode"

end_gcode = G4 ; wait\nM221 S100 ; reset flow\nM900 K0 ; reset LA\n{if print_settings_id=~/.*(DETAIL @MK3|QUALITY @MK3|@0.25 nozzle MK3).*/}M907 E538 ; reset extruder motor current{endif}\nM104 S0 ; turn off temperature\nM140 S0 ; turn off heatbed\nM107 ; turn off fan\n{if max_layer_z < max_print_height}G1 Z{z_offset+min(max_layer_z+30, max_print_height)}{endif} ; Move print head up\nG1 X0 Y200 F3000 ; home X axis\nM84 ; disable motors

ensure_vertical_shell_thickness = 1

external_perimeter_extrusion_width = 0.45

external_perimeter_speed = 25

external_perimeters_first = 0

extra_loading_move = -2

extra_perimeters = 0

extruder_clearance_height = 20

extruder_clearance_radius = 45

extruder_colour = ""

extruder_offset = 0x0

extrusion_axis = E

extrusion_multiplier = 1

extrusion_width = 0.45

fan_always_on = 1

fan_below_layer_time = 100

filament_colour = #FF8000

filament_cooling_final_speed = 3.4

filament_cooling_initial_speed = 2.2

filament_cooling_moves = 4

filament_cost = 24

filament_density = 1.24

filament_deretract_speed = nil

filament_diameter = 1.75

filament_load_time = 0

filament_loading_speed = 28

filament_loading_speed_start = 3

filament_max_volumetric_speed = 15

filament_minimal_purge_on_wipe_tower = 15

filament_notes = ""

filament_ramming_parameters = "120 100 6.6 6.8 7.2 7.6 7.9 8.2 8.7 9.4 9.9 10.0| 0.05 6.6 0.45 6.8 0.95 7.8 1.45 8.3 1.95 9.7 2.45 10 2.95 7.6 3.45 7.6 3.95 7.6 4.45 7.6 4.95 7.6"

filament_retract_before_travel = nil

filament_retract_before_wipe = nil

filament_retract_layer_change = nil

filament_retract_length = nil

filament_retract_lift = nil

filament_retract_lift_above = nil

filament_retract_lift_below = nil

filament_retract_restart_extra = nil

filament_retract_speed = nil

filament_settings_id = "Prusa PLA - First_220-70"

filament_soluble = 0

filament_spool_weight = 230

filament_toolchange_delay = 0

filament_type = PLA

filament_unload_time = 0

filament_unloading_speed = 90

filament_unloading_speed_start = 100

filament_vendor = Made for Prusa

filament_wipe = nil

fill_angle = 45

fill_density = 10%

fill_pattern = gyroid

first_layer_acceleration = 1000

first_layer_bed_temperature = 70

first_layer_extrusion_width = 0.4

first_layer_height = 0.25

first_layer_speed = 20

first_layer_temperature = 220

full_fan_speed_layer = 4

gap_fill_speed = 40

gcode_comments = 0

gcode_flavor = marlin

gcode_label_objects = 1

high_current_on_filament_swap = 0

host_type = octoprint

infill_acceleration = 1000

infill_anchor = 2.5

infill_anchor_max = 12

infill_every_layers = 1

infill_extruder = 1

infill_extrusion_width = 0.45

infill_first = 0

infill_only_where_needed = 0

infill_overlap = 25%

infill_speed = 80

inherits_cummulative = "0.20mm QUALITY @MK3";"Prusa PLA";

interface_shells = 0

ironing = 1

ironing_flowrate = 15%

ironing_spacing = 0.1

ironing_speed = 12

ironing_type = top

layer_gcode = ;AFTER_LAYER_CHANGE\n;[layer_z]

layer_height = 0.2

machine_limits_usage = emit_to_gcode

machine_max_acceleration_e = 5000,5000

machine_max_acceleration_extruding = 1250,1250

machine_max_acceleration_retracting = 1250,1250

machine_max_acceleration_x = 1000,960

machine_max_acceleration_y = 1000,960

machine_max_acceleration_z = 200,200

machine_max_feedrate_e = 120,120

machine_max_feedrate_x = 200,100

machine_max_feedrate_y = 200,100

machine_max_feedrate_z = 12,12

machine_max_jerk_e = 4.5,4.5

machine_max_jerk_x = 8,8

machine_max_jerk_y = 8,8

machine_max_jerk_z = 0.4,0.4

machine_min_extruding_rate = 0,0

machine_min_travel_rate = 0,0

max_fan_speed = 100

max_layer_height = 0.25

max_print_height = 210

max_print_speed = 200

max_volumetric_speed = 0

min_fan_speed = 100

min_layer_height = 0.07

min_print_speed = 15

min_skirt_length = 4

notes =

nozzle_diameter = 0.4

only_retract_when_crossing_perimeters = 0

ooze_prevention = 1

output_filename_format = {input_filename_base}_{layer_height}mm_{filament_type[0]}_{printer_model}_{print_time}.gcode

overhangs = 1

parking_pos_retraction = 92

pause_print_gcode = M601

perimeter_acceleration = 800

perimeter_extruder = 1

perimeter_extrusion_width = 0.45

perimeter_speed = 45

perimeters = 2

physical_printer_settings_id =

post_process =

print_host =

print_settings_id = 0.20mm QUALITY @MK3 - Variable Height

printer_model = MK3

printer_notes = Don't remove the following keywords! These keywords are used in the "compatible printer" condition of the print and filament profiles to link the particular print and filament profiles to this printer profile.\nPRINTER_VENDOR_PRUSA3D\nPRINTER_MODEL_MK3\n

printer_settings_id = Original Prusa i3 MK3

printer_technology = FFF

printer_variant = 0.4

printer_vendor =

printhost_apikey =

printhost_cafile =

raft_layers = 0

remaining_times = 1

resolution = 0

retract_before_travel = 1

retract_before_wipe = 0%

retract_layer_change = 1

retract_length = 0.8

retract_length_toolchange = 4

retract_lift = 0.4

retract_lift_above = 0

retract_lift_below = 209

retract_restart_extra = 0

retract_restart_extra_toolchange = 0

retract_speed = 35

seam_position = nearest

silent_mode = 1

single_extruder_multi_material = 0

single_extruder_multi_material_priming = 0

skirt_distance = 2

skirt_height = 3

skirts = 1

slice_closing_radius = 0.049

slowdown_below_layer_time = 15

small_perimeter_speed = 25

solid_infill_below_area = 0

solid_infill_every_layers = 0

solid_infill_extruder = 1

solid_infill_extrusion_width = 0.45

solid_infill_speed = 80

spiral_vase = 0

standby_temperature_delta = -5

start_filament_gcode = "M900 K{if printer_notes=~/.*PRINTER_MODEL_MINI.*/ and nozzle_diameter[0]==0.6}0.12{elsif printer_notes=~/.*PRINTER_MODEL_MINI.*/ and nozzle_diameter[0]==0.8}0.06{elsif printer_notes=~/.*PRINTER_MODEL_MINI.*/}0.2{elsif nozzle_diameter[0]==0.8}0.01{elsif nozzle_diameter[0]==0.6}0.04{else}0.05{endif} ; Filament gcode LA 1.5\n{if printer_notes=~/.*PRINTER_MODEL_MINI.*/};{elsif printer_notes=~/.*PRINTER_HAS_BOWDEN.*/}M900 K200{elsif nozzle_diameter[0]==0.6}M900 K18{elsif nozzle_diameter[0]==0.8};{else}M900 K30{endif} ; Filament gcode LA 1.0"

start_gcode = M862.3 P "[printer_model]" ; printer model check\nM862.1 P[nozzle_diameter] ; nozzle diameter check\nM115 U3.9.3 ; tell printer latest fw version\nG90 ; use absolute coordinates\nM83 ; extruder relative mode\nM104 S[first_layer_temperature] ; set extruder temp\nM140 S[first_layer_bed_temperature] ; set bed temp\nM190 S[first_layer_bed_temperature] ; wait for bed temp\nM109 S[first_layer_temperature] ; wait for extruder temp\nG28 W ; home all without mesh bed level\nG80 ; mesh bed leveling\nG1 Y-3.0 F1000.0 ; go outside print area\nG92 E0.0\nG1 X60.0 E9.0 F1000.0 ; intro line\nG1 X100.0 E12.5 F1000.0 ; intro line\nG92 E0.0\nM221 S{if layer_height<0.075}100{else}95{endif}\n\n; Don't change E values below. Excessive value can damage the printer.\n{if print_settings_id=~/.*(DETAIL @MK3|QUALITY @MK3).*/}M907 E430 ; set extruder motor current{endif}\n{if print_settings_id=~/.*(SPEED @MK3|DRAFT @MK3).*/}M907 E538 ; set extruder motor current{endif}

support_material = 0

support_material_angle = 0

support_material_auto = 1

support_material_buildplate_only = 0

support_material_contact_distance = 0.1

support_material_enforce_layers = 0

support_material_extruder = 0

support_material_extrusion_width = 0.35

support_material_interface_contact_loops = 0

support_material_interface_extruder = 0

support_material_interface_layers = 2

support_material_interface_spacing = 0.2

support_material_interface_speed = 100%

support_material_pattern = rectilinear

support_material_spacing = 2

support_material_speed = 50

support_material_synchronize_layers = 0

support_material_threshold = 55

support_material_with_sheath = 0

support_material_xy_spacing = 50%

temperature = 210

template_custom_gcode =

thin_walls = 1

threads = 8

thumbnails =

toolchange_gcode =

top_fill_pattern = monotonic

top_infill_extrusion_width = 0.4

top_solid_infill_speed = 40

top_solid_layers = 5

top_solid_min_thickness = 0.7

travel_speed = 180

use_firmware_retraction = 0

use_relative_e_distances = 1

use_volumetric_e = 0

variable_layer_height = 1

wipe = 1

wipe_into_infill = 0

wipe_into_objects = 0

wipe_tower = 1

wipe_tower_bridging = 10

wipe_tower_no_sparse_layers = 0

wipe_tower_rotation_angle = 0

wipe_tower_width = 60

wipe_tower_x = 170

wipe_tower_y = 125

wiping_volumes_extruders = 70,70

wiping_volumes_matrix = 0

xy_size_compensation = 0

z_offset = 0

RE: Gap Fills Issue

Why are you posting a list of settings ? Just save your project from slicer using file>save project and zip it up into an archive and attach it here. That way anyone can open it and slice with exactly the same settings you are using and with the model exactly as you have it. It’s the best way to debug issues.

RE: Gap Fills Issue

Line 37.5 is the problem.

j/k ... Neophyl has a point. This isn't a Linux board where 10,000 lines of text is impressive. Save your setup as a project file, .3MF format. Zip the file into an archive. Then drag it to the open forum text box on your browser, the box turns blue to let you upload the file. Zipped files are allowed, bitmaps like jpegs, pngs, but not stl or 3mf, unfortunately.

RE: Gap Fills Issue

Ok, thanks. I wasn’t sure what’s the best way to share.

Here is the project file. Face_Gaps.3mf

Looking forward to your feedback.

RE: Gap Fills Issue

Was that a picture of your bottom layer? If it was, to get those gaps closed, you need to lower your Z until all of the bits are smooth and squished together with no lines showing.

RE: Gap Fills Issue

I'd agree with Dan that its the usual issue with either an improper live z height calibration or your print sheet needs properly cleaning to get rid of all the oils and grease. From your picture you can see where perimeters on the first layer are sticking out into the hexagon holes or otherwise not adhered to the bed.

While personally I would put your first layer height back to the 0.2 default instead of 0.25 that shouldn't really effect adhesion. Also put your first layer back to default too, at least until you sort out your bed adhesion. If you haven't already use the procedure from here to calibrate your first layer

https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/

I printed your part from the attached 3mf and except for flipping it over to remove the overhanging slope and turning off ironing and it printed out fine on my mk3. No gaps in the bottom beyond what I would expect.

A couple of notes on some of your modified settings though -

-Your pla first layer temp is very high. Put it back to defaults. This looks like another attempt to get your first layer to stick properly. More temp can help sometimes but wont fix an underlying problem with live z or oils/greases contaminating your sheet.

-there is zero point in having ooze prevention enabled in your settings as that is for multi extruder setups and so will do nothing for you.

-you might want to reduce your elephants foot compensation down to 0.1 or even 0. While it might mean you have to remove a slight bit post printing the fact its moving those perimeters in closer to your holes and making the gapfill even thinner might help once you have your basic problem under control.

RE: Gap Fills Issue

@dan-rogers

Thanks dan. I will try it out.

RE: Gap Fills Issue

@neophyl

Thank you that is very helpful. I will try adjusting the Z height and follow your suggestions.

Btw, I don’t have an issue with adhesion. It sticks well.

RE: Gap Fills Issue

A couple of things.

First, why did you set support print speed to 100% -- I can't see any reason to do that, not is it helpful.

Second - you've set layer 1 width to 0.40 mm - a very bad idea - and again there is no reason to do that and did I say it is a bad idea?

Third - you've set layer 1 height to 0.25 mm - a very very bad idea - and almost guarantees bad prints.

Oh - and fifth - why set infill so low on that part? 10% will cause problems in strength and interlayer infill.

RE: Gap Fills Issue

And - the fourth was Ooze prevention only works on printers with multiple extruders - which the Mk3 isn't.

There are other settings that don't make sense, so I have to ask why you are changing all these settings? What prompted you to deviate from defaults?

As for Z-offfset - that looks fine to my eye; the issue others are seeing are due to the height being wrong and under-extrusion caused by the wrong width.

RE: Gap Fills Issue

@tim-2

First Regarding the support speed.

That is the default on my end. I didn’t change it. What should it be?

Second - you've set layer 1 width to 0.40 mm - a very bad idea

The gap between the first passes were wide on the first layer. Once I changed the layer width, it brought them together. Maybe that’s also related to the Z being not close enough to the bed.

Third - you've set layer 1 height to 0.25 mm - a very very bad idea

Not really, See attached. Printed with 0.25 layer height and 0.4 layer width.

why set infill so low on that part? 10% will cause problems in strength and interlayer infill.

I know, these are test prints, the final version will be printed with 15% I even printed down to 5%.

fourth was Ooze prevention only works on printers with multiple extruders

I didn’t know. I will reset it to default.

RE: Gap Fills Issue

@rocky79

Yep - that is not a good layer one. You really should use the defaults and you'll save yourself a crap load of pain in the coming weeks and months.

On the other hand, experimenting and learning what doesn't work can also be fun.

RE: Gap Fills Issue

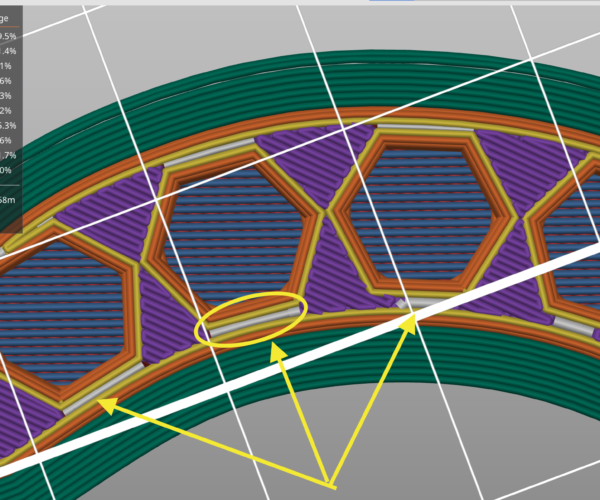

I went back to default settings and I have adjusted the live Z. It still needs minor adjustment.

What do you guys think? I still have gaps here and there.

Is there a way to fill those gaps?

Thanks

Adjusted Layer Height[/caption]

Adjusted Layer Height[/caption]

RE: Gap Fills Issue

Simple answer, no. Sharp corners and crevices will almost always have open spots. By carefully calibrating Linear Advance, and Extrusion Multiplier, you can get closer. But the end point will be overfilled spots and underfilled spots.

Prusa has more to say here:

https://help.prusa3d.com/en/article/linear-advance_2252/

ps: another way to think about it is you are using a round nozzle to fill a square hole, but the filler is not liquid, it's malleable plastic that will never flow into corners.

RE: Gap Fills Issue

As an aside - the PLA you are using has a pigment that flows around in the melt - sorta like metal dust on water. That makes the bright and dark zones you see that accentuate the extrusions. Other filaments don't have this 'feature' and can make rather nice looking parts that don't highlight FFM/FDM printing foibles.

These are typical no effort prints off my printer. Point and shoot using defaults. The lioness required some hand selection of support points, and clean up (wood fiber filament is messy); the nose cone and vise are pretty much slice/print/done - all are copies of other peoples designs.

RE: Gap Fills Issue

@rocky79

Try this

Good Luck

Swiss_Cheese

The Filament Whisperer

RE: Gap Fills Issue

@tim-2

Nice prints. I am using Prusa Filament.

RE: Gap Fills Issue

@swiss_cheese

Thanks for the suggestions. I see the changes you made.

You added top surface ironing. I am only concerned about the first layer, not the top layer.

I also saw you changed the horizontal minimum shell thickness to 0.6mm. How will this affect the first layer gaps?

Thank you