First Project, spool jam and other issues

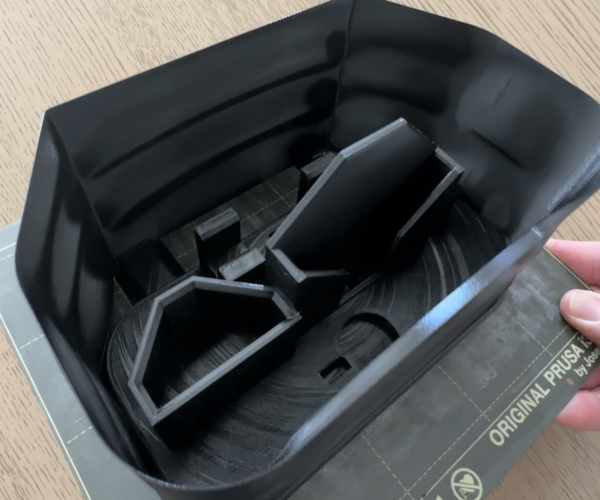

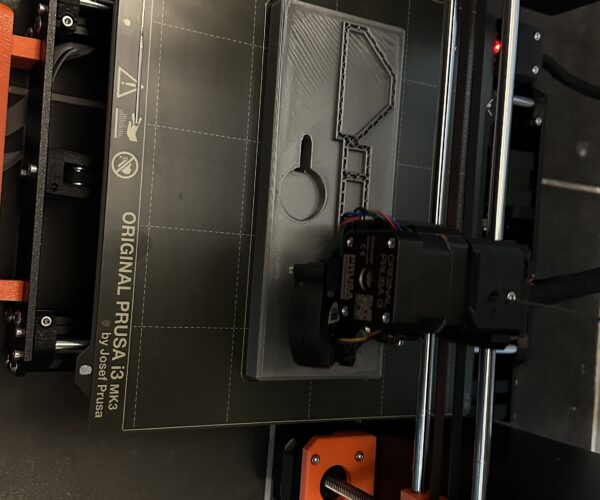

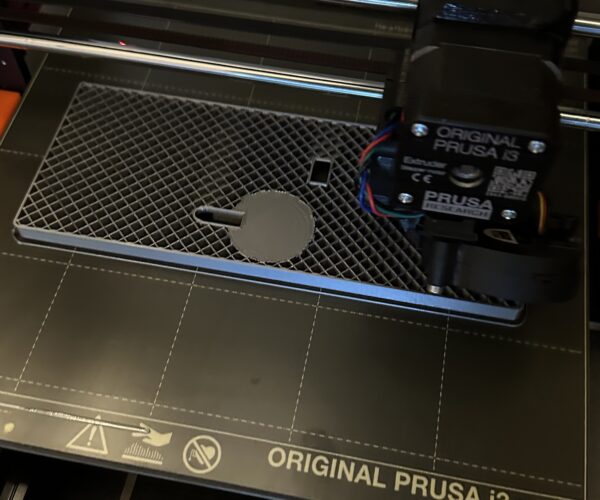

Hello, I am new to 3d printing. I have a MK3S+, printed a few things I got from this site, including the filament guide in the pics. I went for my first project I designed, and the spool jammed right before it finished. I printed this as a draft 0.30, as it was my first design I tried. I see some artifacts in the top layer [near the trapezoid shape you see the diagonal lines falling though] , I was using the standard infill. I was wondering, can anybody help: how do I make sure the spool will not jam like this? is there a better guide to print? Also, what about the top layer (it looks like it was about to fall though in the corner). Thank you for your help, I am sure you all have seen this before. It still fit great, but just need some refinements before printing a final. Thank you for any help.

Best Answer by RandyM9:

The issue you’re having with the top surfaces in the corners is due to the part losing adhesion from the build plate at the corners and warping upwards. The upper layers become over-compressed because the part is arcing upwards towards the hot end.

Start by reading the very thorough reply right below the OP in this thread. This will help you to insure you have a properly dialed in Z height and a squeaky clean print sheet. Once you master these two parameters, your 3D prints will begin to improve.

If you’re still having adhesion issues there are a variety of methods to try including increasing the bed temp, lowering the first layer print speed, or using an adhesion booster / release agent such as glue stick, Layerneer, Magigoo, hairspray, or whatever. Search the forums, there’s plenty of advice on this topic.

And, fwiw, I’ve not had to re-spool a roll of filament yet. Maybe I’m just lucky, but I’m also careful to keep track of the filament end whenever I change rolls. Good luck.

Cheers

RE: First Project, spool jam and other issues

Congrats on your printer acquisition and welcome to the forums.

Generally speaking, it’s rare, but not unheard of, to come across a spool of filament with a tangle from the factory. In most cases, it’s ‘user error’ whereby one loses track of the end of the filament while loading or unloading the roll and that loose end finds its way under an adjacent loop. It may take a while to reveal itself, as in your case.

However the tangle occurred, the only way to positively assure it doesn’t cause another print failure is to manually unspool the roll and re-spool onto an empty holder. I know, a royal pita but what can you do?

Fwiw, your filament guide looks (to my eye, from your pics) like it’s adding unnecessary tension to your extruder. Here’s a link to an alternate that may give you better results. I’ve used a version of this print for a long time with good luck.

looks https://www.printables.com/model/5165-prusa-mk3-filament-guide

Cheers

RE: First Project, spool jam and other issues

Thank you! I will try the new guide. Is re-spooling something you do often? I hadn't thought of re-spooling being necessary but it makes sense. What about the weak corner in picture 3? How it is shwoing the lines like it is falling through? How do I avoid that? thank you for your help.

RE: First Project, spool jam and other issues

The only time I've encountered a jam in this manner is when I've not put away a partial spool with care. In those cases it was really only the first few winds that needed to be re-wound as the rest of the spool was fine.

I guess I'll knock on wood that I don't encounter this problem from a factory wound spool.

Aaron

RE: First Project, spool jam and other issues

The issue you’re having with the top surfaces in the corners is due to the part losing adhesion from the build plate at the corners and warping upwards. The upper layers become over-compressed because the part is arcing upwards towards the hot end.

Start by reading the very thorough reply right below the OP in this thread. This will help you to insure you have a properly dialed in Z height and a squeaky clean print sheet. Once you master these two parameters, your 3D prints will begin to improve.

If you’re still having adhesion issues there are a variety of methods to try including increasing the bed temp, lowering the first layer print speed, or using an adhesion booster / release agent such as glue stick, Layerneer, Magigoo, hairspray, or whatever. Search the forums, there’s plenty of advice on this topic.

And, fwiw, I’ve not had to re-spool a roll of filament yet. Maybe I’m just lucky, but I’m also careful to keep track of the filament end whenever I change rolls. Good luck.

Cheers

It's almost imposible for a new roll of filament to include a tangle - the manufacturer would have to remove a part filled spool from the spooler, invert a loop and then finish to fill ...

Keep control of the end, never let it fly loose or, if you do, unreel a few turns until you are sure there are no crossings and then rewind.

And as @randym9 has written, a thoroughly clean print sheet and accurate first layer 'Z' calibration will fix your adhesion and poor top layer problem.

Cheerio,

RE: First Project, spool jam and other issues

Like diem said, tangled filament is user induced, basically no way that happens during production.

To fix it, respectively make sure it‘s ok: take of a few dozen loops of filament from the spool over the side edge and than wind it back on the spool and make sure you are not letting go of the end. If you do: repeat.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: First Project, spool jam and other issues

ah! good eye. I didn't even notice that. thanks for the link,also, it was helpful. I tried a second time and ran across the same issue. My first layer was dis-bonding during the final stages of the infill printing, even with glue stick. My best guess is that the grid pattern (the long fast runs) were contracting and causing tension. On my third attempt, I was successful. I used the gyroid infill, slowed the infil speed down to 60mm instead of 80, and the top layers where chords instead of straight. I also added brim and a draft shield. This is probably overkill but I wanted to see some success and this time it worked. I'm sure I can tune things a bit for speed/quality but at least I got a funcitonal print out of it!

RE: First Project, spool jam and other issues

even with glue stick.

Glue stick is a release agent. It‘s not increasing adhesion. It‘s used to make models come off easier not stick better. If you are printing PLA on the smooth PEI it is counterproductive to use glue stick. If you encounter adhesion problems you need to check your first layer calibration and clean the surface properly. On tall objects with small bottom surface it‘s also a good idea to use non crossing infill (like gyroid) to reduce the stress on the adhesion.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: First Project, spool jam and other issues

Prusa seems to advertise different.

Glue is a great, easy-to-use tool to increase adhesion. It also creates a protective separation layer. No need for glue specially made for 3D printing. You can use a basic (PVA-based) glue stick. This is supplied with the printer. From our experience, it is not needed when printing PLA, but may it be advisable when printing:...

Glue is a great, easy-to-use tool to increase adhesion. It also creates a protective separation layer.

Even Prusa make mistakes. The second sentence is correct, gluestick is a seperator, essential when printing flex filaments, useful for PETG although there are better alternatives in that case.

For your functional bottom plate cubic infill is likely to give the best rigidity and dimensional stability.

Cheerio,

RE: First Project, spool jam and other issues

@ryan-zierman that‘s not very helpful. The OP had adhesion issues, than used glue stick, which did not solve the issue, I pointed out why that is - because it is not supposed to do that when printing PLA on the smooth PEI. Regardless of what „Prusa advertises“ somewhere, they do say that in their documentation: https://help.prusa3d.com/materials

If PLA does not stick well on the smooth PEI: check the first layer calibration and clean the surface, because PLA sticks very well on the smooth PEI sheet.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE:

@ryan-zierman that‘s not very helpful. The OP had adhesion issues, than used glue stick, which did not solve the issue, I pointed out why that is - because it is not supposed to do that when printing PLA…”

I am the OP.

’Then’ the glue stick solved my adhesion issues, as advertised. Maybe environment, maybe not. It worked great though.

Thank you.

It probably wasn't the glue stick itslf but the washing action of spreading it. You will do better with dishwashing detergent and plenty of HOT water.

Cheerio,

RE: First Project, spool jam and other issues

Thanks for correcting me re glue stick as adhesion booster. Blindly parroting Prusa instructions. Will be more mindful in future.

Cheers

RE:

It probably wasn't the glue stick itslf but the washing action of spreading it.

Or the fact that glue stick adds material onto the PEI and by that effectively reduces the distance to the nozzle, like an increased z-height would. The underlying problem is still not solved, but it seems to be better with glue stick.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!