First prints fine (I think) Triceratops fails every time

Thanks for your time folks.

Finished my build yesterday and after going through calibration I thought I had everything set pretty well. (I have z at -1.510 using the zip tie pinda and live z method).

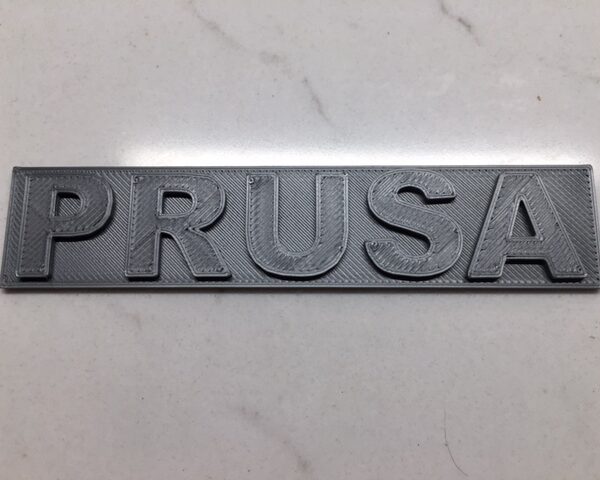

Though I haven't printed in years, I was pretty happy with my prints and how easy the machine is to use after my old Creality CR10S. I printed the Prusa logo plate (normal ), Batarang (stealth), gear thing (stealth) and whistle (stealth), to what I'm calling success(?). I cleaned the plate between all prints with 91% IPA.

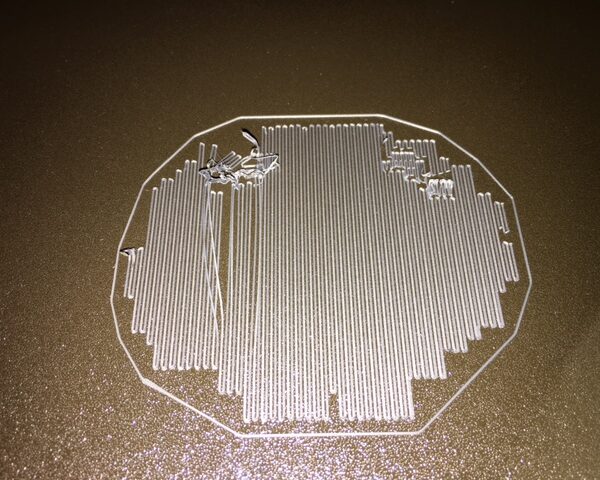

This morning I decided to see how it would do with one of the larger prints and after pulling of the whistle and cleaning above, ran the triceratops at (normal). Total failure twice in a row. Can you help me diagnose? I'm wondering if maybe my success wasn't so good before?

Attempted just minutes after I pulled off the above whistle. The below was my second try. The first was the same.

Is that first layer of the triceratops supports or is all of a sudden my first layer WAY too high for some reason?

Update

Tried printing a benchy. Failed. Dug a little bit, found references to washing with dish soap. Did. Tried printing a file I knew had worked in the past. Failed.

I am now a bit concerned. 😕

Update 2!

Uhm. Then I washed it again, ran the Batarang a third time and printed about exactly as well as the first pictured above. Now I'm not as concerned, but I'm a lot more confused.

Update 3...

So, flush with success, I tried the skull again and got the same failed mess. Ok. Guess I'll wait it out and see if anyone has an idea.

You have (sensibly IMO) been printing progressively difficult prints. Now you have reached the limit of your current settings...

It's hard to be certain from your picture but I suspect your first layer Z setting is a little high, revisit your first layer calibration:

At the end of the calibration you are aiming to print a single layer *sheet*. It should be possible to peel it off in one and fold it without the threads seperating. If it breaks into lines it is too high, not squished enough. If it is a single sheet but with wavy lines or drag marks on it you are too low.

For most people it pays to use 7x7 mesh bed levelling.

Many beginners have problems with the built-in first layer calibration routine. There are alternatives, see this page by a regular poster here: http://projects.ttlexceeded.com/3dprinting_mk3_live_z_calibration.html

and look at this thread: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/

Cheerio,

Live-Z Square 1st attempt

Thanks for the thoughtful response. Below is a picture of my Live-Z sqaure from that link. Bottom right is initial setting after I went through the Prusa stock method. Looks pretty good. I lowered is until it got icky as can be seen, then backed off some until it began looking better. I ended up a *little* lower than I started, but not much. I ended the test at -1.525 down from the -1.51 mentioned above.

As I look closer there IS an area before it goes to hell where it looks like it might be better than where I ended. Should I go again and try to get even closer?

What do you think of the image?

Yes, you passed through your best setting...

Cheerio,

Progress

Alrighty, went through again, settled on -1.53. Guess later on I'll try one of the bigger prints again. Hope I'm not bugging anyone if I come back and share how it goes.

RE: 7x7

Oh, and also switched to 7x7 leveling as well. Thanks for that. Don't see why not really. I mean, some of these prints are 24+ hours. Why shy away from an extra 45 seconds?

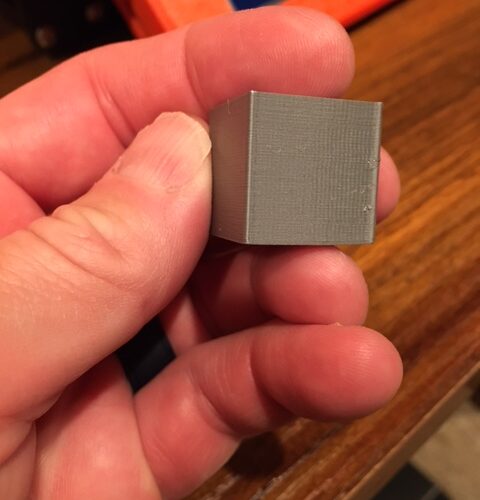

XYZ Cube

Decided to print a calibration cube before doing anything else. Looks better in person than in photos, that's for sure. There are sort of bulges on all the edges between the four XY planes, most pronounced on the left side of the X face. The photo shows that very well. Very little stringing, at least to me. Maybe the Y is a little soft?

Just don't really know what to expect since I haven't FDM printed in a couple of years.

Feel like I should emphasize that the combination of the light, the metallic silver, the camera and the angle of the shot are making this bulge much more pronounced than live, or even to touch, but it's worth noting. I think. Maybe it isn't? Maybe this is just what you get?

Well, crap...

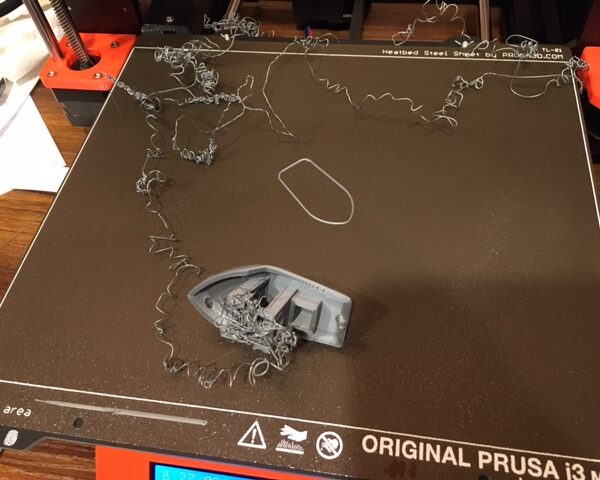

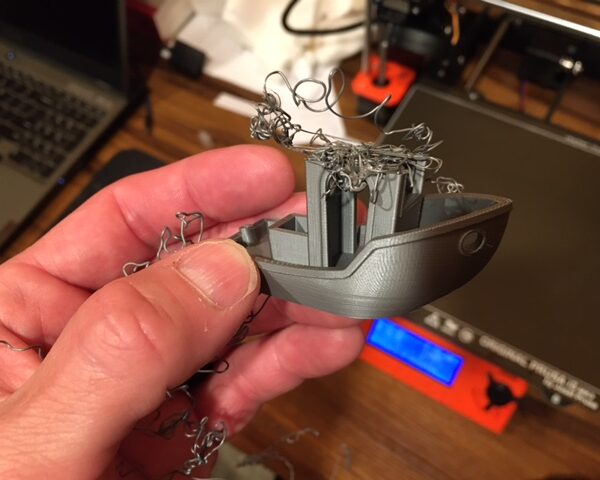

Watched the first few layers print of the benchy. Seemed OK. Came back in an hour or so, still looked good. Watched a movie and came back to find this.

This is becoming fairly frustrating. The CR10S wasn't red hot, but it could print a fricking benchy and cost less than half what this did. I feel like I have first layer nailed down and the build feels tight. The calibration cube looks pretty much fine (to my eyes), but this printer can't seem to reliably span a damned thing. What am I missing here? Filament?

Oh well. To bed.

Benchy is a test object, it is intentionally difficult to print well. The bit you produced looks good, the bottom layer looks OK and there are no signs of major issues.

It failed at the point where curved overhangs tend to warp into the extruder path and put maximum stress on bed adhesion. Very few real life projects do this so your printer is probably OK for run of the mill work.

I would rate that print as good enough for the first month.

Every user builds their printer slightly differently so during the first few weeks of use the printer will run-in and settle its parts together; then you will have to go over the basic maintenance checks, lubricate and recalibrate. Even if you got everything dialled in perfectly today, it would all need re-doing.

Better to settle, temporarily, for a basic working printer and get some useful printing done, make your early mistakes, establish a routine and generally get used to the process. Then when you do your one month service you can take extra care knowing the new settings on your now stable printer are likely to last for several months.

You are printing PLA on a textured bed; it is a little easier to print PLA on a smooth sheet if you have one and PETG on textured but both can work well. The secret is scrupulous cleanliness. PETG then requires a release agent on a smooth sheet (not on a textured) but the underlying sheet must be clean.

Cheerio,

Listen to Diem. The only point I would disagree with him on 🙂 is that its often a lot harder to get pla to stick on the textured bed compared to the smooth one. Especially initially. They seem to take time to 'season' through use.

Beds

Hmm. OK. Didn't know that. Odd that they send you a textured sheet in the box with PLA as the free filament if that's the case. There was a "deal" when I bought the printer for a "free" bed and I either hit the wrong thing or Prusa sent the wrong one because somehow I ended up with two of these textured things instead. Neat. I think it was my "fault" but the description of what was in the box and what was extra was very confusing. Perhaps translation issue?

Now I order a sheet from Czech and wait another two weeks huh?

*sigh*

Grr. Waking up grumpy. 😑

Thanks for your help folks, I appreciate it.

Follow up

Or instead of waiting for that plate should I just switch to PETG? I mean I have half a dozen or so spools of PLA from back in the old days, but they're all at least two years old sitting in their boxes. This stuff goes bad right?

Or... are there quality third party plates that fit the MK3S+ that will work that don't suck?

RE: why not

Or instead of waiting for that plate should I just switch to PETG? I mean I have half a dozen or so spools of PLA from back in the old days, but they're all at least two years old sitting in their boxes. This stuff goes bad right?

Or... are there quality third party plates that fit the MK3S+ that will work that don't suck?

You've got nothing to lose, like others above I only ever use my textured sheet for PTEG and strictly PLA for my smooth PEI plate.

heard the satin is good for both but I don't have one so cant comment.

Had some fun trying to remove some ABA recently off the smooth but that's another story.

Keep in there like the rest of us and your self previously its frustration at times but personally I'm learning from these moments to improve and iron out the issues so they don't occur in the future.

PLA from back in the old days, but they're all at least two years old sitting in their boxes. This stuff goes bad right?

It only goes bad if it gets damp or is left exposed to UV light.

If in boxes it's just damp that matters; if it seems brittle and makes popping sounds when printing - try drying it, there are several threads on here about filament drying.

There is a good chance that it's all still OK or recoverable.

Cheerio,

Flex bed suggestions?

Man is it frustrating sitting here with two identical textured double sided build plates. Grr. I'm having a hell of a time finding smooth surface beds to fit the MK3. Am I missing something? Everything 3rd party seems to be textured or rated poorly. I see the one on the Prusa website but it'll ring me up for another $50 which is a hard pill to swallow considering I thought I was getting one "free" with my $800 printer. Given the above info and reading reviews on Prusa's website, I think it's reckless to include this textured build plate as the default with PLA in the box.

I'll go ahead and order the Prusa if I must, but I'm not necessarily happy about having to do so.

RE: Don’t buy another plate, try PETG first

I’m an absolute beginner to 3D printing and have a new MK3S+ that I built from a kit. I chose Prusa after reading many positive reviews and seeing how large and involved the user community is.

Like you, I ordered the textured powder coated build plate, primarily because of the “ease of use” touted by the manufacturer. I also received a complimentary spool of Prusa galaxy grey PLA filament with my order.

I took plenty of time and care with the build and everything checked out on startup. I had absolutely no idea what a “first layer” was really supposed to look like or feel like, so dialing in the “z” height setting was a mystery. And using the built-in calibration was an exercise in futility.

When I finally figured out (through much trial and error, plus searching this forum) how to get a proper first layer, it was time to try my first print. I used the Prusa logo file that came on the included memory card. Somewhere I read that this was also a good file choice to check your first layer since it just prints a flat rectangle to start. I actually stopped a bunch of prints after the first layer to see if I was getting what I thought I should be getting.

Through all this, i was having constant issues getting the first layer to stick to the sheet. When I let the Prusa logo continue to print, it would invariably warp at a corner after a few layers and then the print head would knock it completely loose and I had to bail out of the print.

I learned about the inherent problems with the textured sheet and PLA in particular on this board. I also learned how to clean the sheet with hot water, a new, unused scotch bright type of sponge, and Dawn dish detergent. I even ran the sheet through my dishwasher in a high temp cycle with sanitizer rinse to try to really degrease it.

After all this, it worked marginally better and I got through the logo print. But only once, then nothing would stick again until I washed the plate with soap and water. Apparently PLA leaves a residue behind that causes problems.

So, long story short, like you, I looked for an alternate build plate without having to spend another $50 for the smooth Prusa plate and wait for shipping to the US. And like you, nothing really struck me as acceptable. So instead, I ordered a spool of PETG from Amazon and the next day I was printing with a material that actually sticks to the build surface and allows me to start printing real parts with success. Bear in mind, ymmv. Some people say they can’t get anything to stick to the powder coated sheet. But it’s worth a try for a $20 roll of PETG. Btw, I bought the Overture brand in several colors and so far it’s been great.

Thanks to all the kind folks on this board who tirelessly respond to the questions that mystify beginners like me. Without @JeffJordan “life adjust Z - my way” calibration files and @bobstro with his deep knowledge and incredible patience (to name just two) I’d be completely lost. I honestly thought I had made a huge mistake and that I would never sort out how to 3D print.

Hang in there, I’m sure you’ll get it sorted. Good luck!