First layer ok, but other layers fail

I've been having a problem with my prints recently. The first layer is okay, but subsequent layers fail to adhere well and are stringy/brittle. I've been printing with PLA Prusament/PLA+ GST3D filaments and using the recommended temperature settings for the nozzle (215C) and heat bed 60C). One observation is that the printer seems to click a lot after the first layer. I understand that printing speed ramps up, but loosening or tightening the idler screw doesn't seem to help the problem. I've adjusted nozzle/bed temperatures, Z-axis height, readjusted the PINDA, slowed down printing speed, but nothing seems to work. Could it be a damaged nozzle or something else? I've only been using the printer for about 2 weeks since assembly.

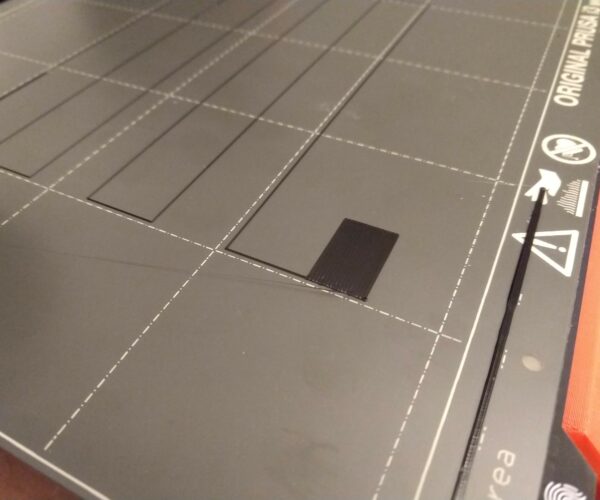

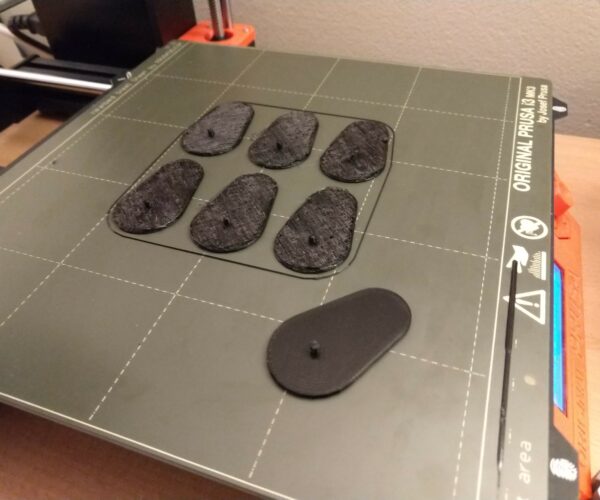

New prints compared to a sample from last week on the same printer. New prints are brittle and layers are diffuse.

New prints compared to a sample from last week on the same printer. New prints are brittle and layers are diffuse.

RE: First layer ok, but other layers fail

It almost looks like the nozzle is scraping against the layer it's laying, and then it's raised up, and then each pass makes it messier and messier. I've had it happen and create a real hairy mess. The first layer looks like it might be too hot. I know you said that you've tested different temperatures etc, but that's all I can think of?

RE: First layer ok, but other layers fail

Time to learn how to do COLD PULL ... there are FAQ's on how best to do this on the Prusa site. Also, next time you get to printing, and you notice underextrusion and clicking (a symptom of a plugged nozzle), unload the filament and inspect the end for any thick stubs. If you see one measure it and report back. 2.2 mm would be bad.

As for brittle prints, some filaments will get brittle if they have absorbed a lot of moisture; but usually with PLA it's benign.

You might also want to invest in a spool of cleaning filament. It can help when changing filament types.

As a PS, watch getting fingerprints on the print sheet - they will come back to haunt you in a very bad way. And no - alcohol doesn't really remove them. Soap and water does.

pps: some day I'll learn to touch type... lol

RE: First layer ok, but other layers fail

I just had the same thing recently. It ended up being a blocked nozzle.

In searching through why my nozzle blocked, I had my filament temperature too low for my setup.

I don't know where I read it but it was here somewhere. The clue to if you have a nozzle blockage is a curve on the slow extrusion. If the leak extrusion is straight, you don't have a blockage. If the extrusion curves back up and sticks to the nozzle, its a blockage.

This is what I did to fix it on my end.

#1 unloaded my filament

#2 increased nozzle temp to 285 for 2 minutes to let anything that will drain out, drain out.

#3 I pushed the needle that came with the MK3s into the hole about 2 cm.

#4 loaded my cleaning filament just to double check.

So far, that was enough to fix it for me without needing the cold pull. I hope it is of some help...