Different line thickness in X and Y axis

Hi all,

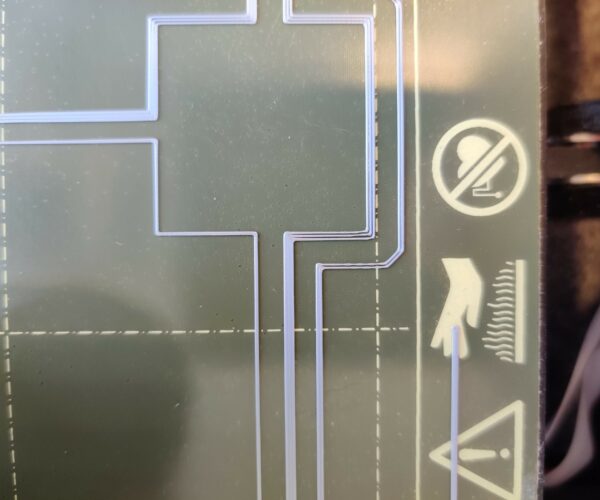

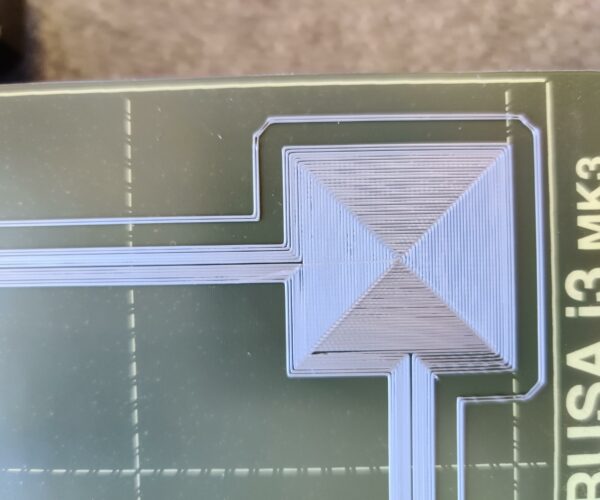

after reading some documents and helps about calibrating I'm trying to calibrate my new MK3S. But I have no idea what to do with this - when printer is moving in X axis, the line is noticeably thicker then when its moving in Y axis. Attaching some photos.

Any ideas what could be wrong? The profile is default PLA from PrusaSlicer. PLA is silver Prusament from printer package.

Thanks. Michal.

PS: I don't known why the pictures are turned by 90 degrees. Don't see any option how to turn them.

RE: Different line thickness in X and Y axis

Your live Z is not nearly negative enough.

Use this thread/guide/part to get it dialled in correctly:

RE: Different line thickness in X and Y axis

More info leading up to this point would be helpful.

This a new printer setup or have you been printing with out issues and it just started doing that?

RE: Different line thickness in X and Y axis

Guessing without much info, check all your belts for right tension, make sure all the belt gears are tight and with the machine off move the X and Y axis making sure they are nice and smooth.

RE: Different line thickness in X and Y axis

Hello again.

I'm so sorry I didn't answer earlier. Last two days was quite busy.

The printer is brand new. It was a building kit. I spend more then two days on assembling on granite surface block. But I'm sure the printer is perfectly assembled as possible.

According to your advise I tune the belt tension a litlle bit, check the smoothness of moving on X and Y axis. I also make another few Z axis calibrations and what was really helpfull, a mesh bed leveling. It makes printed first layer lines much more consistent.

I wish to thank you both for help.

Just one more question - for what for is "Lin. correction" option (after mesh bed levelling) in settings menu? I didn't find anything about it.

Thanks. Michal.