Consistent print problems on part of bed

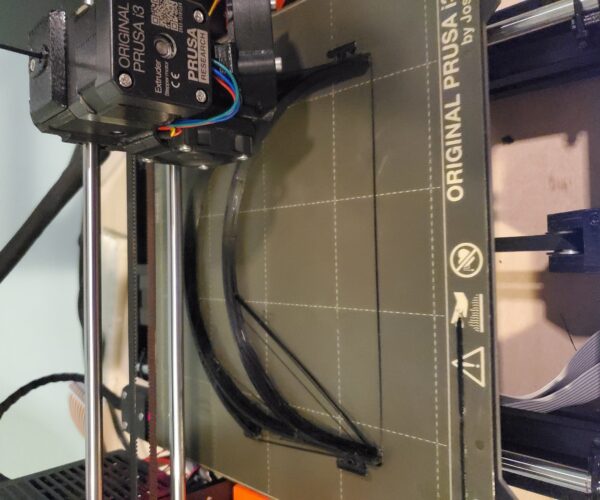

I've been printing a bunch of the face shields and was generally having good luck, but now I'm having a consistent problem where half of the print looks great and the other half looks terrible (see attached image). I'm somewhat new to this so don't have a lot of experience troubleshooting print problems and am not too sure where to start. I reviewed Prusa's resources on remedying common print problems and tried some of their basic things. I cleaned the nozzle with the needle and made sure to thoroughly clean the bed and the hot end of any extra filament, but neither of those things helped.

I assume what I'm seeing is probably a somewhat common problem, but I'm at a loss of what to try next. Any suggestions would be appreciated! Thanks!

RE: Consistent print problems on part of bed

Those bits of material stretched across the brim at the left are extrusions that didn't adhere sufficiently to the underlying layer. As the nozzle moves, they're under tension, so come loose and pull taut like that. Try bumping your temps 5-10C for better inter-layer adhesion at speed. Slowing down will work too, but I assume you're after quick results. You might have to experiment with both.

If you're mass producing, be aware that bed adhesion will go at some point. Give the PEI sheet a wash under hot water with plain dish soap (Dawn or Fairy). Scrub it with a clean paper towel and dry it with another. Avoid touching the print area. Do nothing else and adhesion should be restored.

Good luck. Let us know how we can help.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Consistent print problems on part of bed

@bobstro Awesome, thanks so much! I'll give all this a try! Do you think bed adhesion is the reason it's consistently only happening on the left side of the bed?

RE: Consistent print problems on part of bed

Just a thought, are you using 7x7 Mesh bed levelling? (Available from the LCD Menu)

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Consistent print problems on part of bed

@joantabb

Yes, it runs the mesh bed leveling before each print.

RE: Consistent print problems on part of bed

Update: I increased the nozzle temp and thoroughly cleaning both sides of the print bed with dish soap and then also decided to try using the other side of the sheet. I then tried another print and noticed this shifting/misalignment)happening on the first layer, again only on the left side of the bed.

RE: Consistent print problems on part of bed

Hi Alec, does the mesh bed levelling test 49 different points on the bed?

Have you tried moving the extruder from side to side by hand, if so, is the movement smooth? is there any jerkiness?

did you Lube, your Linear bearings during the build?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Consistent print problems on part of bed

@joantabb

Sorry, I misunderstood your question as I didn't realize there was 7x7 bed leveling in addition to the 3x3. I'm just using the 3x3 bed leveling.

When I move the extruder along the x axis it feels pretty smooth except for at each end (particularly the left end) it feels a little jerky.

I did not lube the bearings during the build. For reference, I've had the printer for a little over a month and haven't used it much up until I started mass producing 25+ face shields in the last week or so.

RE: Consistent print problems on part of bed

I would suggest that you try lubricating the bearings, and switching to 7x7 mesh bed levelling, and see what happens.

Here is a link to the Prusa Maintenance suggestions https://help.prusa3d.com/en/article/i3-printers-regular-maintenance_2072#rods-and-bearings

I am a bit of a renegade... I wash my Build plates (Shock Horror, Ghasp... "that will void your warrantee" the Nay Sayers claim... and worse, I lubed my bearings from Day One on all of my printers, (Except the SL1) the SL1 was a Beta Test machine, so I tested it 'completely as supplied' in line with the beta test requirements. I only made changes that Prusa instructed me to make.

I also replace my heatbed power wires with Flexible Silicone insulated wires so they will last longer than the Prusa supplied wires (I have had two prusa heat bed wires break on me. the new wires have 252 fine conductors instead of 22 conductors in the wires used by prusa)mthe new wires will last a lot longer than the prusa wires.)

I also put Heatsink paste on the heatbreak threads inside the cooling fins(for better cooling), and Coppa Slip on the heatbreak to heater block and nozzle threads, for better heat transfer and so that they are less likely to get gunged with molten filament at a later date,

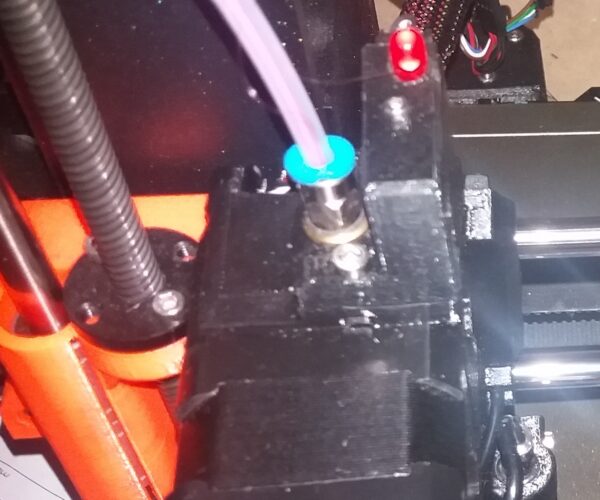

Oh, and I put 5volt LED's on my filament sensors to make it easier to see when they trigger...  this one has the cover off to see how easy the 'Mod' is...

this one has the cover off to see how easy the 'Mod' is...

Best of luck with your printer,

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK