Calibration Advice

Had my MK3s for about a week now and have been printing non-stop. Part quality has been generally good but I could use some advice.

I jumped right in with PLA and made a benchy, followed by a bunch of stuff for my kids. Moved on to some work-related items and then started printing medical PPE stuff. During the switch to PPE, I changed filaments to Prusament PETG. Immediately i started having first layer issues. Nozzle gumming up quickly, what looked like plowing, huge deposits of material upon each retraction. This led to several failures as the excess material would sometimes catch during the next layer via the stuck on PETG on the sides of the nozzle. I spent a LOT of time doing z calibration and got something that I think looks very good. Even then, the plowing and excess deposits persisted. Finally, I just slowed things down BIG time for the first layer and settled on 10mm/s. This allowed me to get through the first layer and then whatever issue I'm seeing didn't make much of a difference in the faster, upper layers.

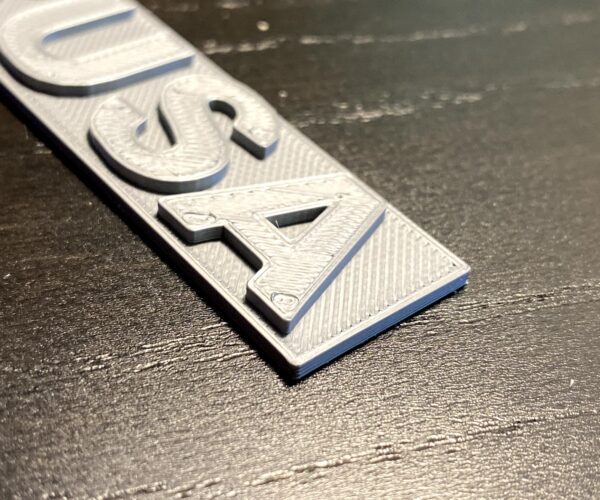

Today, I switched back to PLA and I'm noticing the same "leftovers" at retraction spots. This occurs at every layer. I went ahead and ran a Prusa logo to show this off. The rest of the print looks pretty good to me.

First prints:

The last pic above was printed with PETG (as well as the medical PPE). All the rest was with PLA.

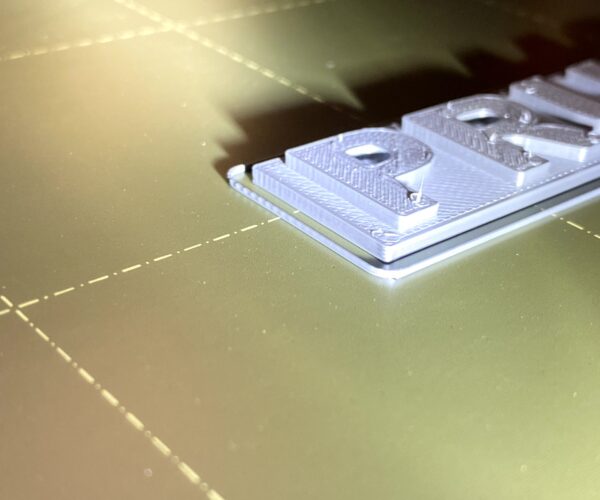

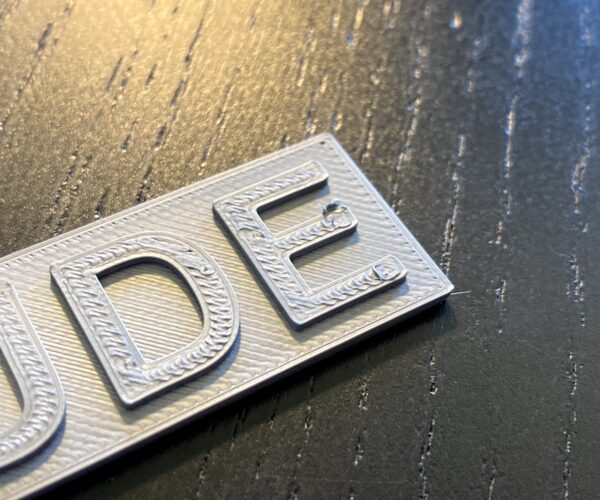

Pictures below are from when I switched back to PLA with the Prusa logo.

These pictures clearly show the deposits that form under retractions. They also show a few weird lines on the bottom surface. I manually caused this by pressing down slightly on the bed during the first layer. I've noticed that there is some vibration in the y-axis during motion changes. It's definitely audible and it I've seen some "slight shakiness" in Y direction lines during printing. These show up well in the skirt loops. I'm curious if my bearings are meh or just need to be tightened. I'll post a video of the vibration next.

Any advice would be greatly appreciated!

RE: Calibration Advice

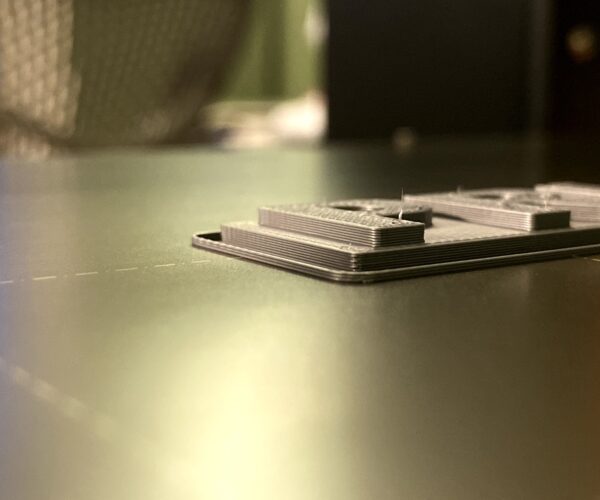

Y-axis issue showing up in y movements. Notice how you can see the vibration wave dissipate in the skirt. The fast movement causes the wave to dissipate over the length of the move. On the actual printed part, the vibration works itself out much quicker due to the lower speed.

RE: Calibration Advice

Video of the vibration. This is at a pretty low speed so you can imagine how much higher pitch/louder it gets during a big print.

RE: Calibration Advice

How to calibratie first layer.

Also clean bed with dish soap, every few prints, and with small print , do it every print.

if you change between different material, also clean with dish soap.

Let us see a picture of your first layer?

RE: Calibration Advice

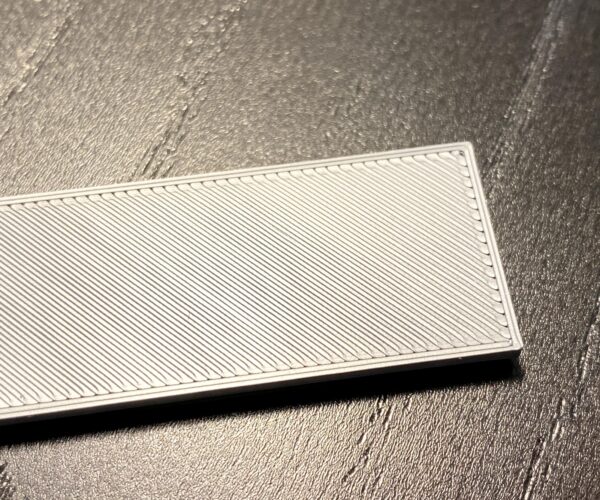

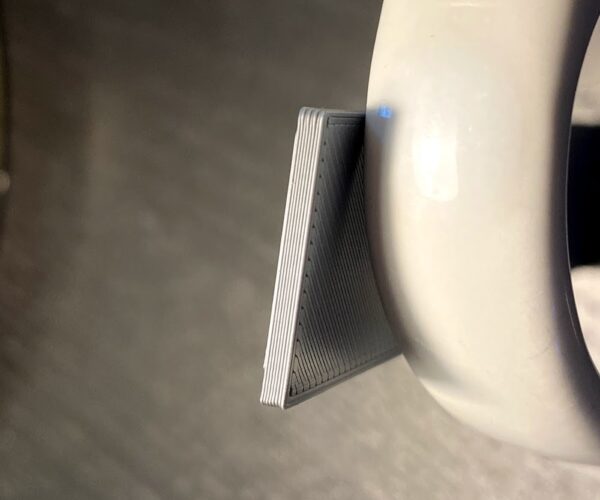

I spent some time today looking at everything I could and figured that it was just extruding too much material. I backed down the extrusion multiplier to 0.9 and made some test prints. Clearly, for this PLA at least, the extrusion multiplier had a massive impact. I tried with blue and orange later today and both of those were a bit under=extruded at 0.9. Had to bump them up mid-print.

Multiplier set to 1.0

Multiplier set to 1.0 (top) and 0.9 (bottom)

The visual cube at 0.9

RE: Calibration Advice

Take several measurements of the actual filament diameter with calipers along 2-3 metres length and then adjust your filament settings to match the real world values. That way the numbers slicer is using to work out the extruding are much more accurate. Basically this should be done at least for every new brand and often for different colours even within the brand.

RE: Calibration Advice

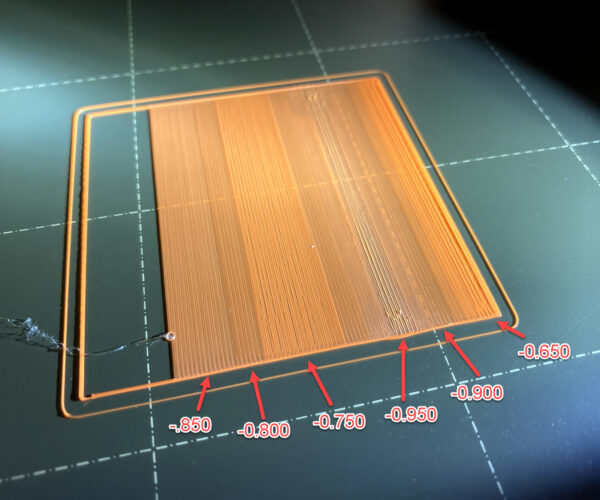

I'm going with -0.850 right now and things are working well. Manually dialing back filament flow (which I assume is the same as extrusion multiplier in PrusaSlicer) is what I'm doing to combat over extrusion on a per filament basis.