Bed adhesion problem

Hi

I find it next to impossible to get my prints stick to the textured sheet.

It's a brand new printer and sheet. I'm not new to printing but new to Prusa. Have been using BuildTak pei sheets for a few years but first time I try a textured.

First prints with prusament silver pla roll that was supplied with machine was hit & miss printing the test files on the SD card. First layer looked good and skirt was measured near first layer height after calibration.

Moved to Petg that usually sits like glued to pei but no way...

Cleaned plate with dishwash liquid and hot water, still no.

Cleaned with IPA, first print ok. Next and all after , no.

Bottom surface looks really good, just like the printed parts for the machine.

Have tried several Z values from low to high, slowing down, increasing first layer flow and temp.

Nothing seems to do it.

It's working fine first 10 minutes then it gets loose, skirt still sits fine though.

Z hop is set high, 2mm.

Help please...

Have not calibrated the smooth pei yet so don't know if that's better but the textured plate obviously work for others.

Best Answer by JayElectrics:

Once again from computer...

Hi, some of the below steps are against Prusa's recommendations, so use at your own risk (I do).

I found 2 solutions to the Textured Sheet adhesion problem:

1) I bought another gold textured sheet from AliExpress (cheaper, better adhesion). However, the sheet has a different texture.

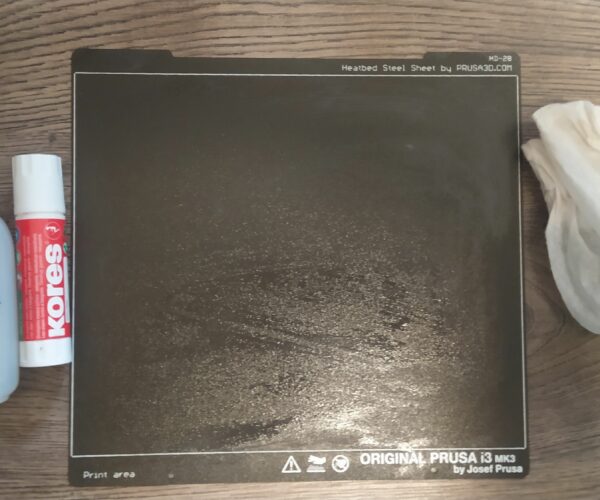

2) I prepare the surface using: Kores GLUE STICK + ALCOHOL(technical) + washed&dry CLEANING/BABY WIPE following these steps:

- I washed the textured print sheet from both sides with water and washing-up liquid, then rinse it with warm water. Dry the sheet using paper kitchen tissues immediately! (Prusa does not recommend using water due to possible development of rust). You never need to repeat this step unless your sheet becomes greasy or dirty.

- Put the print sheet on a clean surface (like table but not the printer!) Apply GLUE STICK using zig-zag lines, not too much - just a few lines (8-12) only to 1 side of the print sheet.

- Spray or pour the ALCOHOL to the center of the print sheet and start spreading it with the (washed and dry) CLEANING WIPE using circular or spiral motion from the center to the edges. You should get a honey/syrup like consistency of the glue. If it starts drying and sticking, put more alcohol. Continue distribution of the glue until you get consistent layer of the sticky liquid over the whole plate. In the end, you can do hatch pattern so the surface looks a bit better to the eye.

- Once the layer is roughly even, check there is no mess on the other (clean) side and you can put the plate (glued side upwards!) on the heatbed and start printing. The alcohol will evaporate almost immediately on the hot bed, long time before it finishes calibration. Mark the glued side by sticker or marker, once it dries, you will hardly notice the layer of glue.

I use this procedure every 1-4 prints, depending on the print size, area used to print and time (it is less sticky after a few days). It solved my issues with small to medium size prints. Some problems persist when printing full height objects (very tall prints). In some situations, increasing the bed temperature by 5-10°C might help a bit.

Please, let me know your thoughts or observations. I hope these tips help you.

Jay

RE: Bed adhesion problem

I got the mk3 cause everyone was raving about the textured sheet. Waited a year to get it, only to have the same results as you.

I can only get PET-G to stick to the textured sheet, and I can only get PLA to stick to the smooth sheet when using certain gluesticks.

RE:

Thanks mate,looks like were in the same boat then.

Tried the smooth pei sheet and it sticks like super glued to it.

RE: Bed adhesion problem

I might have a solution but my post repeatedly crashed when posting. 🙄

RE: Bed adhesion problem

Winners are those who never give up 😉

RE:

Once again from computer...

Hi, some of the below steps are against Prusa's recommendations, so use at your own risk (I do).

I found 2 solutions to the Textured Sheet adhesion problem:

1) I bought another gold textured sheet from AliExpress (cheaper, better adhesion). However, the sheet has a different texture.

2) I prepare the surface using: Kores GLUE STICK + ALCOHOL(technical) + washed&dry CLEANING/BABY WIPE following these steps:

- I washed the textured print sheet from both sides with water and washing-up liquid, then rinse it with warm water. Dry the sheet using paper kitchen tissues immediately! (Prusa does not recommend using water due to possible development of rust). You never need to repeat this step unless your sheet becomes greasy or dirty.

- Put the print sheet on a clean surface (like table but not the printer!) Apply GLUE STICK using zig-zag lines, not too much - just a few lines (8-12) only to 1 side of the print sheet.

- Spray or pour the ALCOHOL to the center of the print sheet and start spreading it with the (washed and dry) CLEANING WIPE using circular or spiral motion from the center to the edges. You should get a honey/syrup like consistency of the glue. If it starts drying and sticking, put more alcohol. Continue distribution of the glue until you get consistent layer of the sticky liquid over the whole plate. In the end, you can do hatch pattern so the surface looks a bit better to the eye.

- Once the layer is roughly even, check there is no mess on the other (clean) side and you can put the plate (glued side upwards!) on the heatbed and start printing. The alcohol will evaporate almost immediately on the hot bed, long time before it finishes calibration. Mark the glued side by sticker or marker, once it dries, you will hardly notice the layer of glue.

I use this procedure every 1-4 prints, depending on the print size, area used to print and time (it is less sticky after a few days). It solved my issues with small to medium size prints. Some problems persist when printing full height objects (very tall prints). In some situations, increasing the bed temperature by 5-10°C might help a bit.

Please, let me know your thoughts or observations. I hope these tips help you.

Jay

RE: Bed adhesion problem

One more VERY IMPORTANT observation I made and forgot to mention:

In my case, it looks like all textured sheets require much thinner 1st layer = Z axis adjustment -0.1 to -0.15mm in comparison to the smooth print sheet. The first layer almost needs to be "ironed into the print sheet" texture. I never had a problem with the smooth print sheet because it tolerates 1st layer inconsistency and much more variation. The textured sheets do not not tolerate high 1st layer nor heatbed level issues!

TIP: I have a small issue with my bed level and had to adjust the slope (my bed is leaning downwards toward the back by +0.2mm). Before the correction, my prints would only stick in the front and separate and the back. Checking and eventually adjusting the bed level correction might be worth a try.

If you print a large single-layer square over the print sheet and examine the texture carefully (eye, caliper), you will see immediately, how precise is your 1st layer...

RE: Bed adhesion problem

Thanks I'll give that a try.

I have a la ready tried the wash and squishing really hard.

The glue and alcohol was new to me so that might be the missing element that turn it to success.

You mention your bed is tilted, is the mesh data available somewhere?

RE: Bed adhesion problem

Yes the glue & alcohol seems to do it 🙂

Just printed 4 identical pieces on the same spot, all fine. Might adjust Z little lower. I measured a 0,3 layer to 0,25 so maybe 0,05 to 0,1mm lower as suggested.

Bottom surface looks great, need to work a bit more on the top but overall very happy with it now.

Printed with 0,3 layer height in AddNorth PETG.

RE: Bed adhesion problem

Yes the glue & alcohol seems to do it 🙂

Just printed 4 identical pieces on the same spot, all fine. Might adjust Z little lower. I measured a 0,3 layer to 0,25 so maybe 0,05 to 0,1mm lower as suggested.

Bottom surface looks great, need to work a bit more on the top but overall very happy with it now.

Printed with 0,3 layer height in AddNorth PETG.