Alignment and table adherence

Hi all,

I am a first-time user and I am so happy with my first 3D printer and excited to print. I assembled the MK3S run all the adjustments and printed my first pieces, I could say reasonable good. Was all thick and large bases printers. Then I started printing some thin pieces and noticed a few errors on bed level e adhesion.

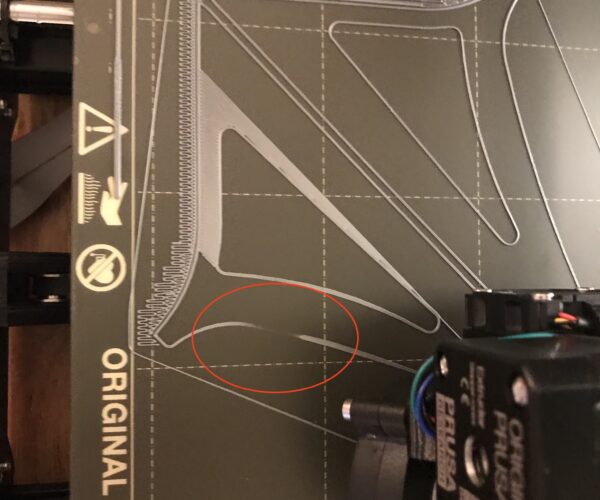

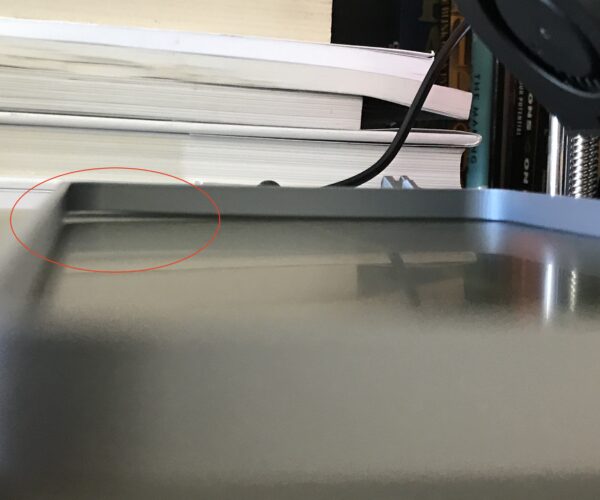

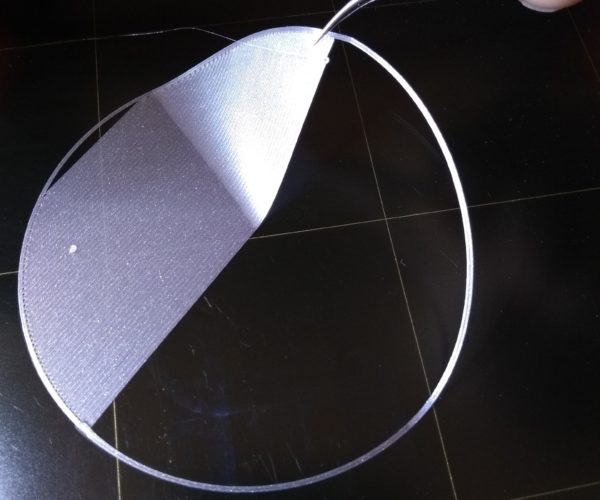

First I noticed that there is a part on the bed that is higher than the rest, but I don't know how to level. (IMG_4689, IMG_4690, and IMG_4700) bu the end result was usable in my shop.

Second I am trying to print a Funnel to my dust collection and the walls are relatively thin, I tried 4x to print, and no adhesion to the bed after a few layers. I look here in the forum and clean with hot water and soap, an abundance of alcohol. I used glue that came with the printer, no success. I don't know what to do. Looks like it warped. (IMG_4733)

I would greatly appreciate any guidance.

Gus

RE: Alignment and table adherence

-Clean bed with dish soap, a few times, and use hot water, and do not toch the bed with your fingers.

-Adjust your first layer to be 100%.

Both are needed to get a 100% sticking to bed.

Use 7x7 bed calibration is a setting in your printer.

Wind, cold wind can warp the model! You can try to print colder or hotter.

Big flat models,

Slower first layer,

more heat in first layer to get more sticking,

more heat in bed could help.

Extra you can use glue, look in forum what you can use, or printer shops.

Test with different filament brand could also help.

RE: Alignment and table adherence

@peter-m26

Thank you, Peter. I am going to clean again and redo the calibration. I tried with glue, but I look for another type of glue that maybe works.

Gus

RE: Alignment and table adherence

The smooth PEI sheet absolutely does not need glue to work very well with PLA. Glue generally makes it worse.

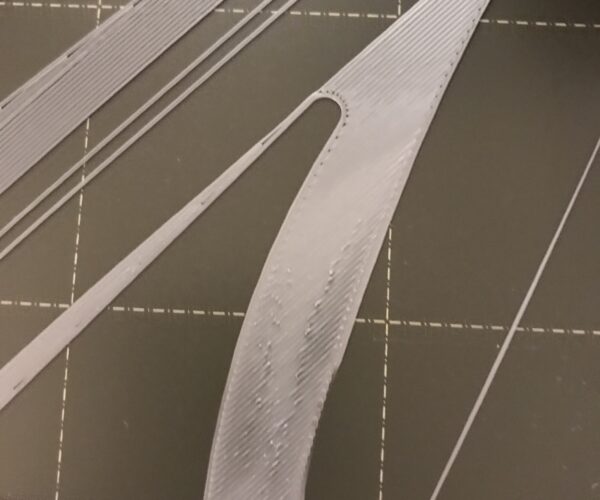

Layer one is key. And it looks like your layer one is much to high. Said another way, your Live-Z calibration needs to go lower. Try printing this cal sheet - the result should be a single sheet of plastic 0.2 mm thick - with no gaps or ridges between tracks.

Also - soap and hot water is the best cleaning method. Easy, cheap, and works every time.

RE: Alignment and table adherence

It also looks like you are not doing a bed level before printing. What slicer are you using?

RE: Alignment and table adherence

@tim-m30

Hi Tim,

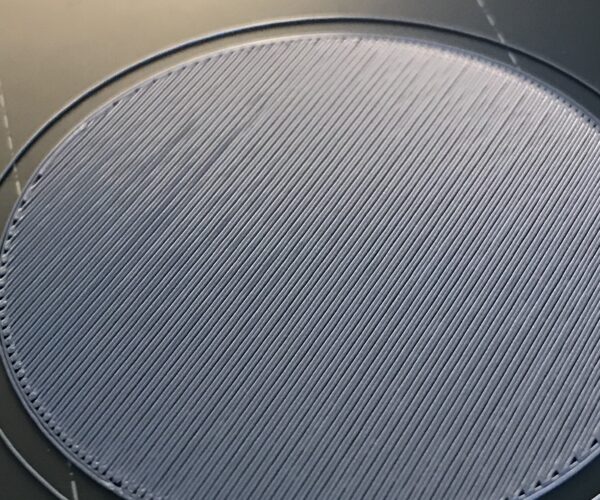

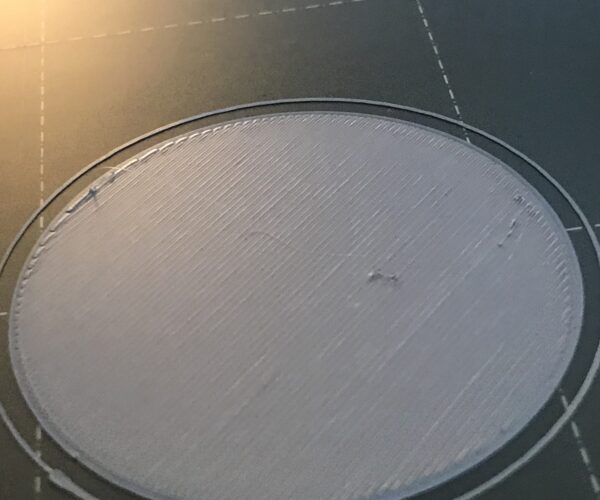

Thank you for the Cal-Circles file, I printed and I am attaching the result (as you said, I need to go lower). The printer every time that starts a new print it does the calibration, that one in 9 points, is that you mentioned?

Thank you,

Gus

RE: Alignment and table adherence

Hi,

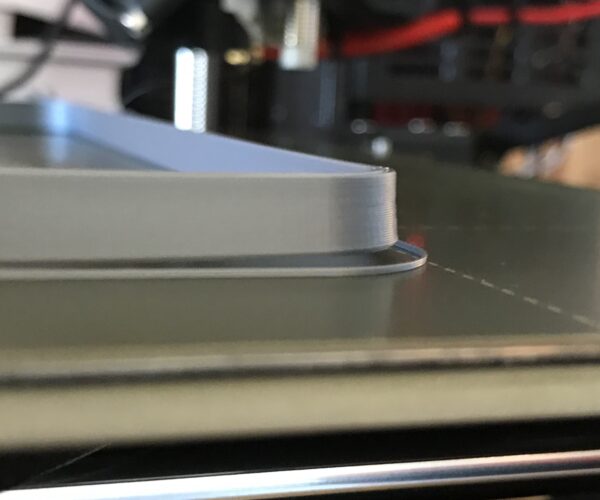

I lowered the Z and reprinted the circle, looks much better than before. But at the edges still looks different than the rest. This could be bed level?

*I tried to update the post above, but my time was expired.

Thank you,

Gus

RE: Alignment and table adherence

Okay - you went a bit too far in the Live-Z adjustment. You need to come up a bit. The circles are large enough you can make the adjustment while you are printing the circle. Adjust 25 um and wait a few seconds to see the result.

You can open the live-z menu by pressing the button and selecting Live-Z ... I think later versions of firmware make it even easier.

And, you should select the 7 x 7 point bed level, not the 3 x 3 level. 7x7 is much better.

RE: Alignment and table adherence

@tim-m30

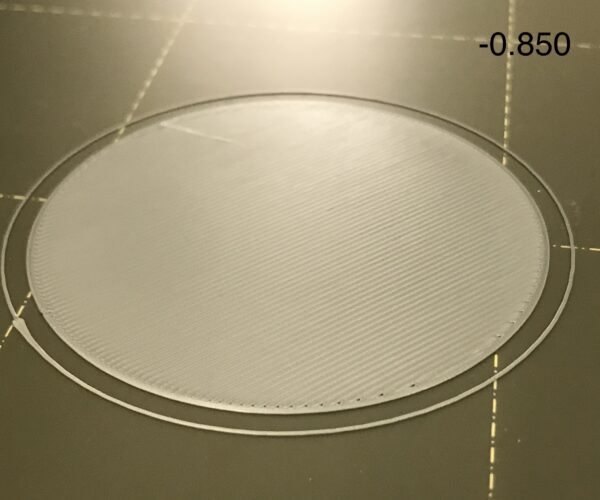

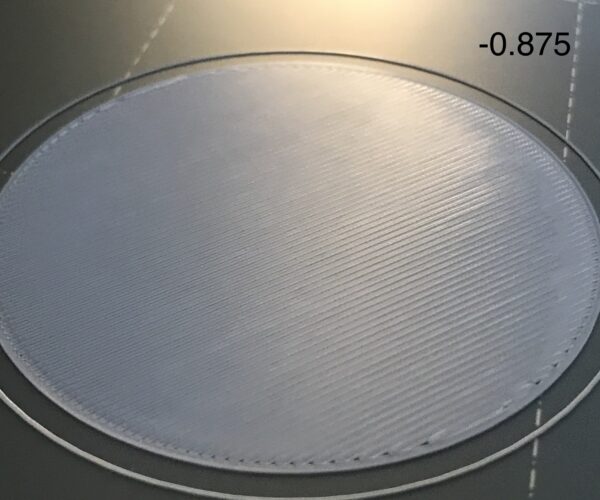

I selected the 7x7 points and did 2 tests with -0.875 and -0.850. My previous configuration was -0.900. I did a -0.825, but I stopped in the middle because it was easy to see that it was too far.

But now, I can't distinguish between .875 and .850. I think .850.

Thanks,

Gus

RE: Alignment and table adherence

And remember that temperature change of the PINDA can cause a 0.025 mm shift all on it's own. That's why I have my startup g-code wait for the PINDA to be 37c when printing.

RE: Alignment and table adherence

@tim-m30

I found this, is the same as you did for yours?

G76: PINDA probe temperature calibration

G76 echo PINDA probe calibration start echo start temperature: 35.0° echo ... echo PINDA temperature -- Z shift (mm): 0.---

I just don't know how to use it.

Thank you,

Gus

RE: Alignment and table adherence

Not mine - I'm not aware the Mk3 firmware allows the use of "echo" commands. And G76 isn't anything you'd call during printing.

In Slicer - under Printer Settings: Custom G-code, Start G-code: replace what's there with this: then save as a new Printer Profile (e.g., MK3-custom).

Here's my startup gcode, in it's entirety.

M115 U3.7.1 ; tell printer latest fw version

G90 ; use absolute coordinates

M83 ; extruder relative mode

; M104 = set hot end temp

; M109 = wait for hot end temp <Sxxx and Rxxx interchangable>

; M140 = set bed temp

; M190 = wait for bed temp <Sxxx ignores too hot, and Rxxx waits for heats or cools as needed>

; cool down PINDA

M106 S255 ; turn on fan

M104 S0 ; turn off nozzle heat

M140 S0 ; turn off bed heat

M860 S35 ; wait until PINDA is less than 35C

M106 S0 ; turn off fan

; preheat nozzle to a low temp, get plastic mushy before driving into the bed with G28

M140 S[first_layer_bed_temperature] ; set bed temp

M109 R175 ; wait for extruder temp

M190 R[first_layer_bed_temperature] ; set & wait for bed temp

G28 W ; home all without mesh bed level

; soak PINDA then level

G0 X50 Y50 Z1 F3000; this is a good PINDA heating position

M860 S37.5 ; wait until PINDA is >= 35C in winter, 37.5C spring/fall, 40C summer

G80 N7 R5; mesh bed leveling

; heat to extrude temp

G0 X0 Y-3.0 Z10 F3000; this is a good nozzle heating position

M109 R[first_layer_temperature] ; set & wait extruder temp

; purge

G1 Y-3.0 Z0.20 F1000.0 ; go outside print area

G92 E0.0

G1 X1.0 Y-1.0 E0.5 F500.0 ; scribble 1

G1 X1.0 Y-3.0 E0.5 F500.0 ; scribble 1

G1 X2.0 Y-1.0 E0.5 F500.0 ; scribble 2

G1 X2.0 Y-3.0 E0.5 F500.0 ; scribble 2

G1 X3.0 Y-1.0 E0.5 F500.0 ; scribble 3

G1 X3.0 Y-3.0 E0.5 F500.0 ; scribble 3

G1 X60.0 E9.0 F1000.0 ; intro line

G1 X100.0 E12.0 F1200.0 ; intro line

G1 X97.0 F2000.0 ; wipe left

G1 X105.0 F3000.0 ; wipe right

G92 E0.0

M221 S{if layer_height<0.075}100{else}95{endif}

; end Printer Start gcode

RE: Alignment and table adherence

@tim-m30

Awesome, thank you! I will try it.

RE: Alignment and table adherence

Posted by: @tim-m30

Here's my startup gcode, in it's entirety.

...

Hi Tim-- if I use your custom start code, is it ok to leave these default commands at the end?

; Don't change E values below. Excessive value can damage the printer.

{if print_settings_id=~/.*(DETAIL @MK3|QUALITY @MK3).*/}M907 E430 ; set extruder motor current{endif}

{if print_settings_id=~/.*(SPEED @MK3|DRAFT @MK3).*/}M907 E538 ; set extruder motor current{endif}

RE: Alignment and table adherence

I've never used those commands - must be something in recent firmware I have yet to use. So yeah, I can't see any reason to not include them if they are in the standard Prusa printer profiles. And I just looked now that I just installed 3.9.1 ... and yes, I'll be adding them to my start code.