adhesion/warping on flat prints

I have finally assembled, calibrated and successfully created my first ever 3D print on my MK3S+. I just have a few beginner, basic questions. first off is a warping issue when printing flat objects for instance the Prusa sample file, when printing after several layers the corners are lifting and not adhering to the smooth steel sheet I am using this being after a thorough cleaning with isopropyl alcohol. the print finally comes loose entirely and the print is has to be aborted. what can be done to counter this? can the bed heat be increased? (if so, is this done in the slicer when creating the G code?) what are my other options, perhaps the glue stick? another basic question is should the filament be unloaded after printing is complete and before shutting off? thats all for now, thanks in advance for any help. Chris

RE: adhesion/warping on flat prints

Hi Chris.

Welcome to the group,

I assume that you are printing with the Silver PLA Filament, supplied with the Printer and that you are using the Smooth PEI Build plate.

Usually these work well together.

In my Experience IPA is a misunderstood solvent.

to be effective on a 3D printer, the build plate needs to be cold, the application fabric needs to be contaminant free and you need to use plenty of IPA.

If you use a previously washed cloth, then there may be traces of Conditioner on the cloth, which the IPA can mobilise and spread evenly across your build plate,

Similarly IPA can take your finger grease and apply it to the build plate. too little IPA can simply spread whatever contaminant you have on the build plate, more evenly across the whole surface,

I prefer to use a new dedicated kitchen sponge with Hot Water and a little Dish Soap, to wash contaminants off the build plate, then I rinse well with plain hot water, and dry immediately with plain paper towels.

the Prusa Mk3 series printers come out of the box, with 3x3 mesh bed levelling, set as default. (this tests 9 points on the build plate)

I prefer to enable 7x7 mesh bed levelling (this tests 49 points on the build plate) whish I consider a better option.

so I suggest that you use 7x7 for your first prints. (enable, using the LCD menu)

Additionally first layer calibration can be difficult to achieve. in my opinion, the Prusa first layer calibration tool, is hard to tune in.

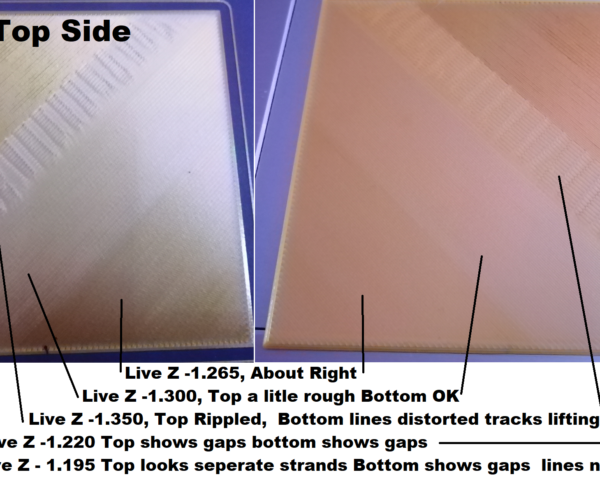

So I prefer to use the 'Life Adjust 'Z' My Way' Process where you use a rectangular patch to tune in the filament squish so that you get a smooth panel of filament with all traces of filament fused together into a single patch.

I will link to the Life Adjust Z My Way thread, below.

there is a test patch for the three most commonly used filaments at the bottom of the first post. however the first layer of the Prusa Logo, can achieve the same effect.

the actual values in the diagram, are peculiar to MY printer, yours will probably be different. Live Z will always be a negative number.

once you have a scrupulously clean build plate, and a good first layer, PLA should adhere very well to your PEI buildplate.

in fact your models may be difficult to remove...

wait for the build plate to cool before trying to remove your models

If the models prove difficult to remove, you can try putting the build plate in the freezer for a couple of minutes. or try dribbling IPA around the base of the model and letting it soak for a while, then remove the model carefully,

For larger models, you can raise the bed temperature a little, (I use 70C) for PLA... this is normally done whilst slicing. (Change the values under the filament settings drop down menu)

if you have a pre sliced model, you c n change the bet temperature from the LCD Display, after the print starts.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

The common reasons for warping/adhesion problems are:

A dirty print-sheet - you've thought of that.

Non optimal first layer Z configuration - if unsure show us the result *on the print bed* : this may be your problem.

Cold drafts or just very cold ambient air.

Incorrect or misapplied seperators or adhesion promotors - you don't need either so rule that out.

There are other that mostly apply to thicker prints but start here.

Cheerio,

RE: adhesion/warping on flat prints

@joantabb - very nicely summarized. This should be a sticky at the top of the forum pages.

Thank you for your attention to detail and incredible patience.

Cheers

RE: adhesion/warping on flat prints

Hey @JoanTabb, thanks for the thorough explanation and for the link to correctly live-configure Z. Getting the nozzle height right is a dark art; that post really helped me!

RE: adhesion/warping on flat prints

My Pleasure

adhesion is the most useful factor in 3D printing...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK